Ejection-drive closed-loop backflow pulse-type transonic wind tunnel flow field control method

A closed-loop control and control method technology, applied in the direction of electric fluid pressure control, fluid pressure control, non-electric variable control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

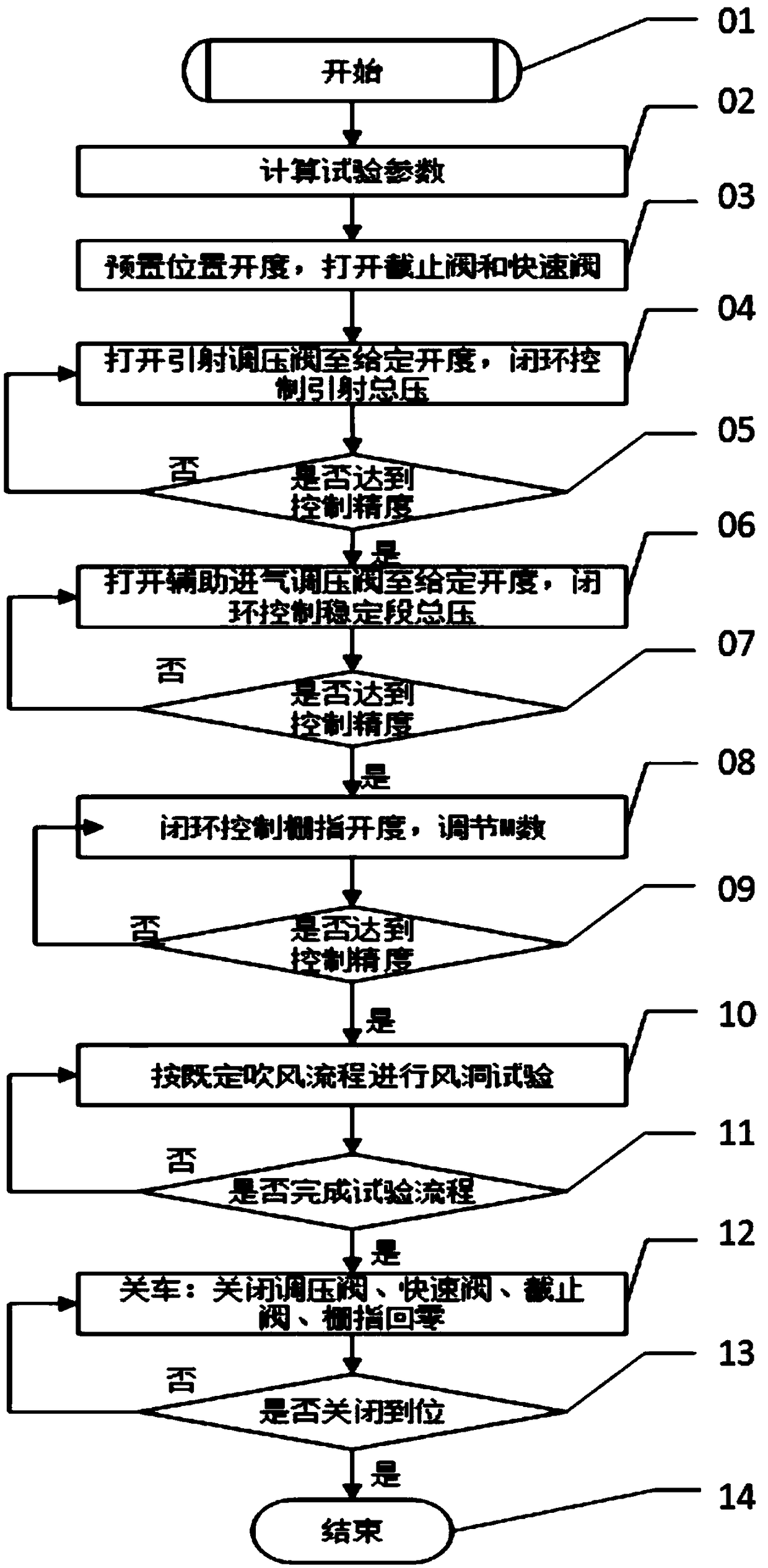

[0070] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0071] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

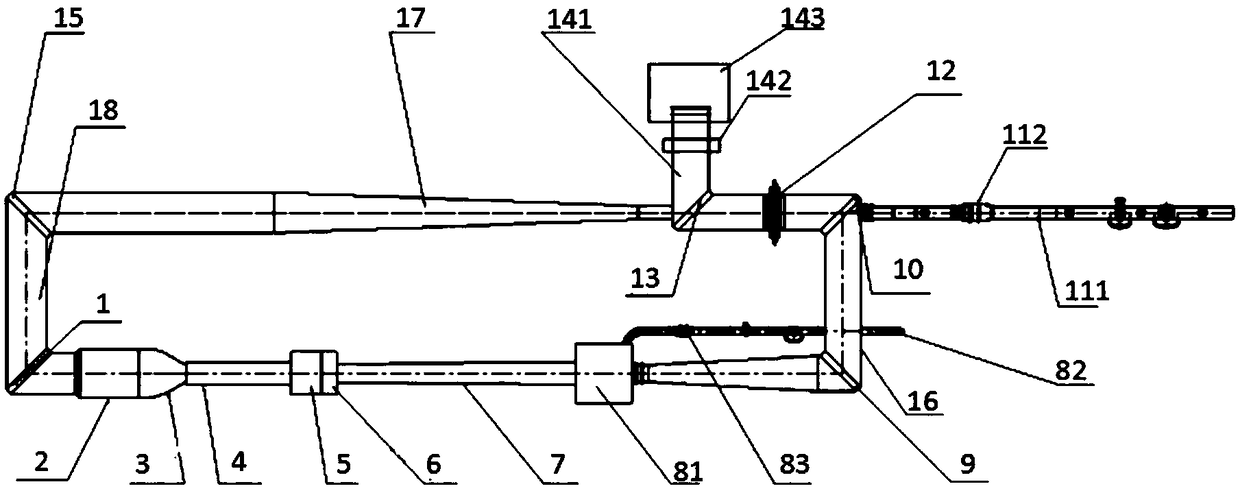

[0072] figure 1 It is a schematic diagram of the aerodynamic profile of the wind tunnel related to the present invention, such as figure 1 As shown, the wind tunnel includes: return pipeline; fourth corner section 1, stable section 2, contraction section 3, nozzle section 4, test section 5, bracket section 6, diffuser section 7, injection 8, the first corner section 9, the second corner section 10, the auxiliary air intake system 11, the backflow regulating valve 12, the fifth corner section 13, the exhaust system 14 and the third corner section 15;

[0073] Wherein, the ejecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com