Optical unit and optical unit with 3-axis shake correction function

An optical unit and optical element technology, applied in optics, instruments, cameras, etc., can solve the problems of large driving force and large power consumption, and achieve the effect of reducing tolerance, reducing power consumption, and suppressing image defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

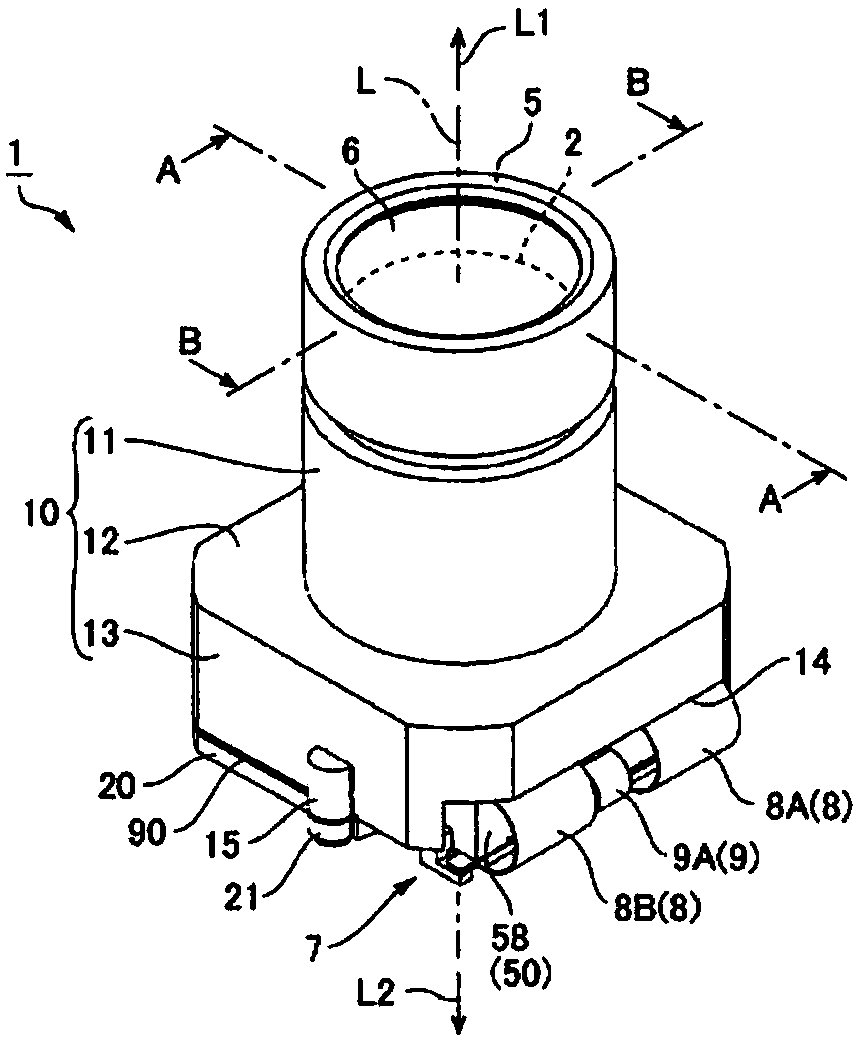

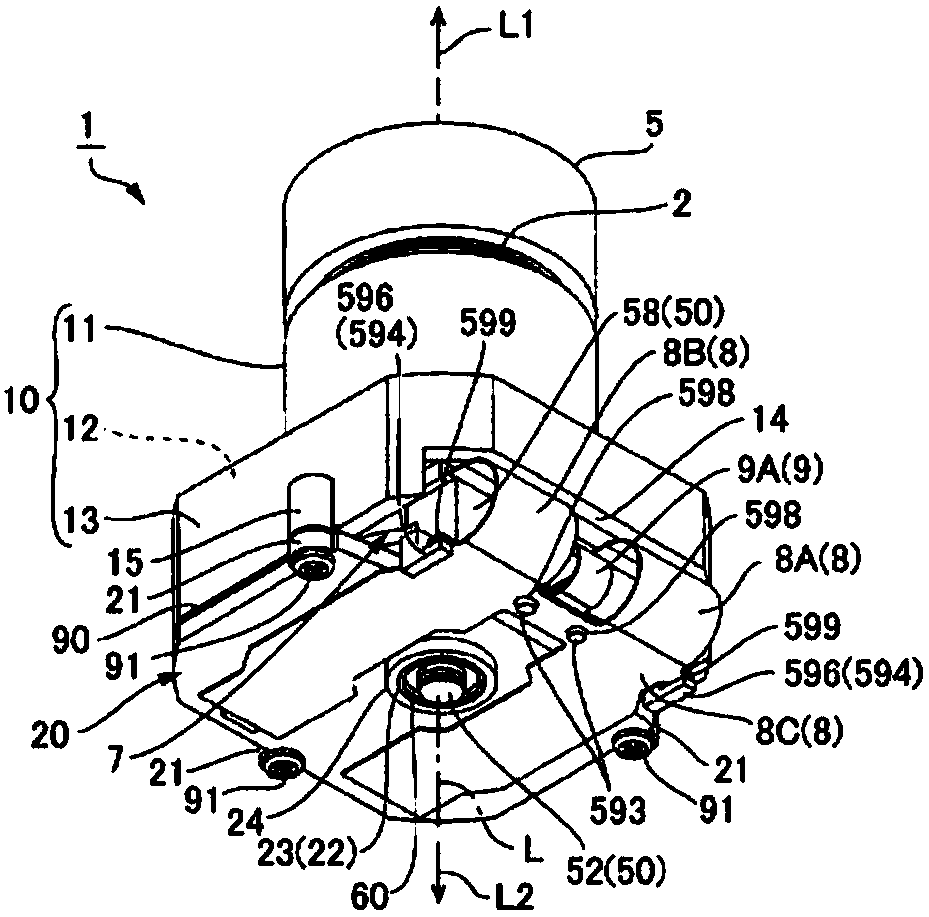

[0163] Hereinafter, embodiments of the optical unit 1 to which the present invention is applied will be described with reference to the drawings. In this specification, the symbol L is the optical axis of the optical unit 1 , the L1 direction is the object side in the optical axis L direction, and the L2 direction is the opposite object side in the optical axis L direction.

[0164] Fig. 1 (a) and Fig. 1 (b) are the perspective views of the optical unit 1 to which the present invention is applied, Fig. 1 (a) is the perspective view observed from the subject side L1, Fig. 1 (b) is the perspective view from the reverse subject Perspective view from side L2. in addition, figure 2 , image 3 It is a sectional view of the optical unit 1 of Fig. 1(a) and Fig. 1(b), figure 2 It is the A-A sectional view of Fig. 1 (a), image 3 It is a B-B sectional view of Fig. 1(a). As shown in FIG. 1(a) and FIG. 1(b), the optical unit 1 includes a lens unit 2, a lens holder 10 as a holder memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com