Mixing device for various microbeads

A mixing device and microbead technology, applied in the directions of roads, road repairs, roads, etc., can solve the problems of uneven mixing of glass microbeads, difficult to control the spreading amount of glass microbeads, etc., so as to improve the reflection or continuous reflection effect, and the structure is simple. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] like Figures 1 to 3 As shown, a variety of bead mixing devices in this embodiment include: a variety of bead mixing devices, including: a pre-mixer 1, a mouthpiece 2 and a spreading device 3, the pre-mixer 1 is a tubular structure, The inside of the pre-mixer 1 is provided with a helical piece, the upper end of the pre-mixer 1 is the inlet of glass beads, the lower end of the pre-mixer 1 communicates with the upper ends of several sub-mouths 2, and the lower end of the sub-mouths 2 is connected to The entrance of the spreading device 3 is connected;

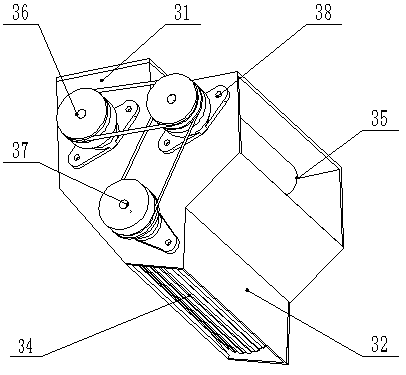

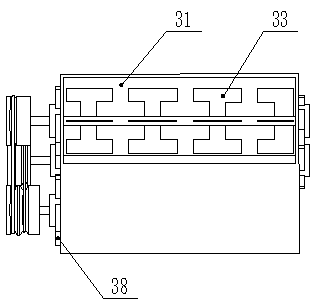

[0023] Described sowing device 3 comprises: stirring chamber 31, sowing chamber 32, blade wheel 33, sowing shaft 34, speed-regulating motor 35, first transmission wheel 36 and second transmission wheel 37, and described agitation chamber 31 and sowing chamber 32 all It is a cavity with upper and lower ends open and sealed around. The lower end of the stirring chamber 31 communicates with the upper end of the spreading ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com