Construction lifter control system

A construction elevator and control system technology, applied in elevators, elevators in buildings, transportation and packaging, etc., can solve the problems of mechanical locks with loud noise, construction elevators parked at the leveling position, and single function, to avoid collisions. effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] refer to figure 1  ̄ figure 2 , a construction hoist control system of the present invention is characterized in that it includes:

[0056] PLC1: for logic control;

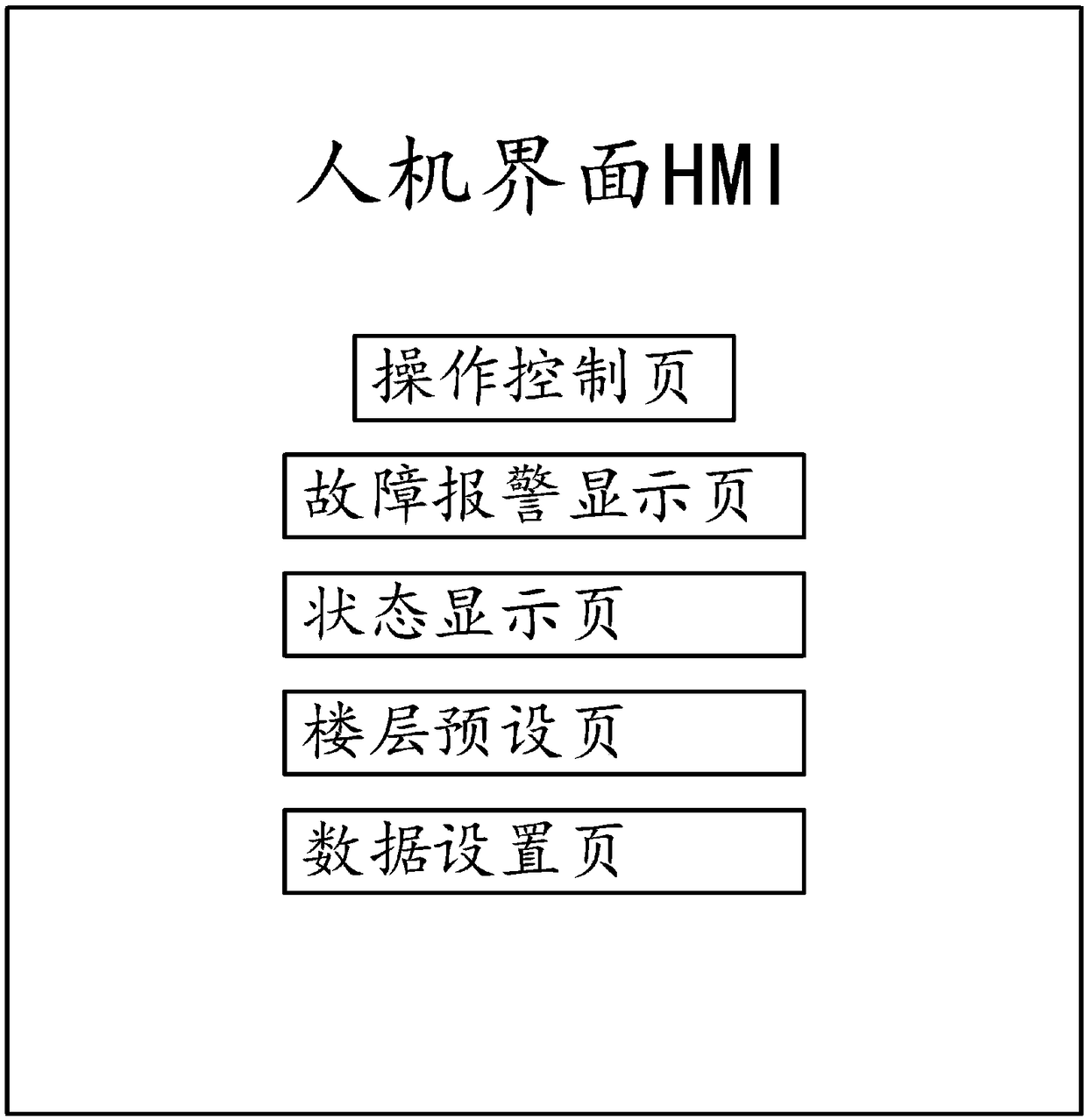

[0057] Human-machine interface HMI2: used for command and data input, status indication and fault indication;

[0058] Encoder 3: used to detect the height of the lift;

[0059] Inverter 4: used to control the running speed and running direction of the motor;

[0060] Motor 5: used to drive the movement of the elevator;

[0061] Control handle 6: used to manually operate the lift;

[0062] Electric lock switch 7: used to switch between manual operation mode and automatic leveling operation mode;

[0063] The PLC1 is electrically connected to the human-machine interface HMI2, the encoder 3, the frequency converter 4, the control handle 6, and the electric lock switch 7 respectively; the frequency converter 4 is electrically connected to the motor 5; Switch the operation mode of the elevator to manual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com