Impurity removing and winding device for processing coated fabrics

A fabric and coating technology, which is applied in the field of textile processing, can solve the problems of vibration and falling of fabrics, complicated ways of taking off the reel, etc., and achieve the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, when placing the fabric roll, first pass the cylinder shaft through the through hole in the middle of the fabric roll, and then place the cylinder shaft on the semicircular holes of the two pillars 14, so that the fabric roll is just placed in the gap between the two pillars 14 Then insert the post at the bottom of the auxiliary block 15 into the slot on the pillar 14, then insert the locking lever 16 from the side, and upwardly pull the puller at one end of the locking lever 16 to lock and fix.

Embodiment 2

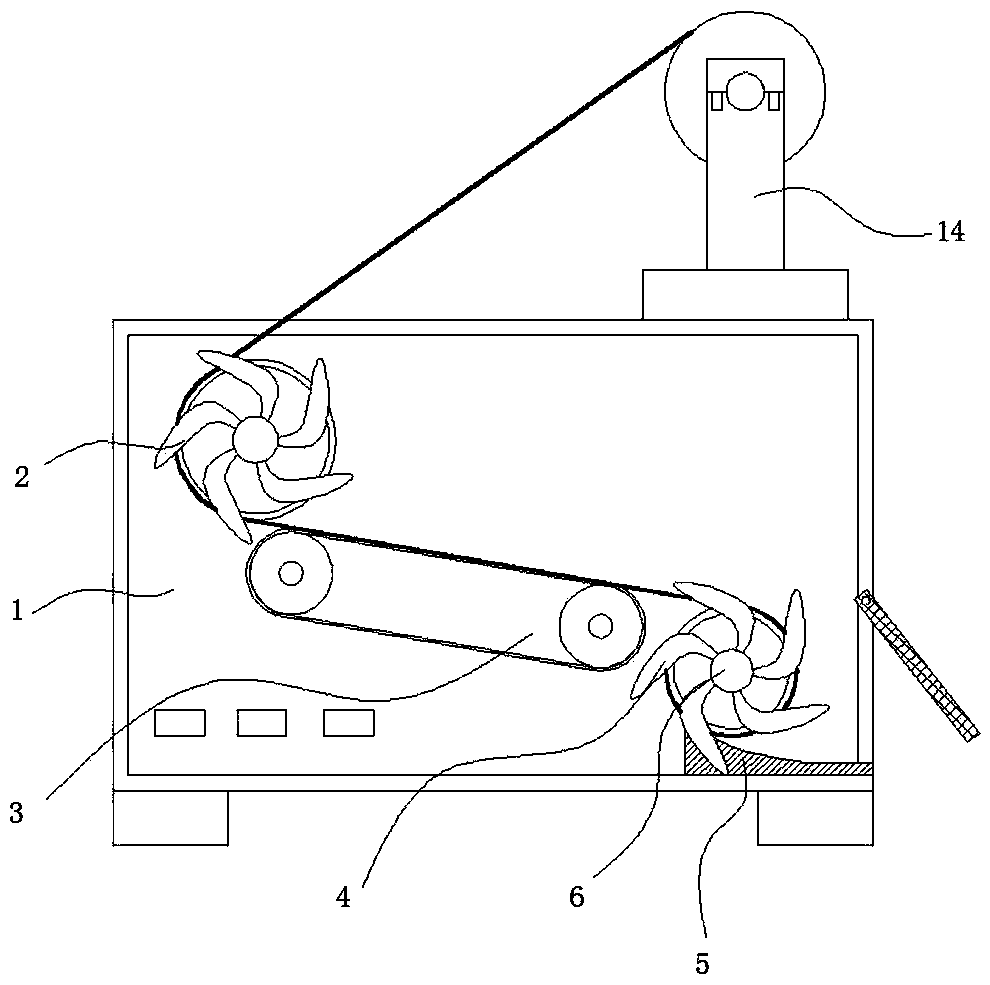

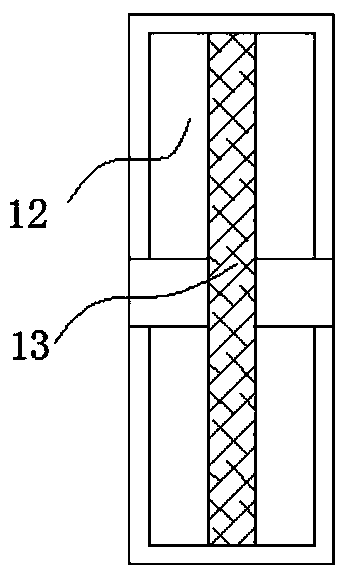

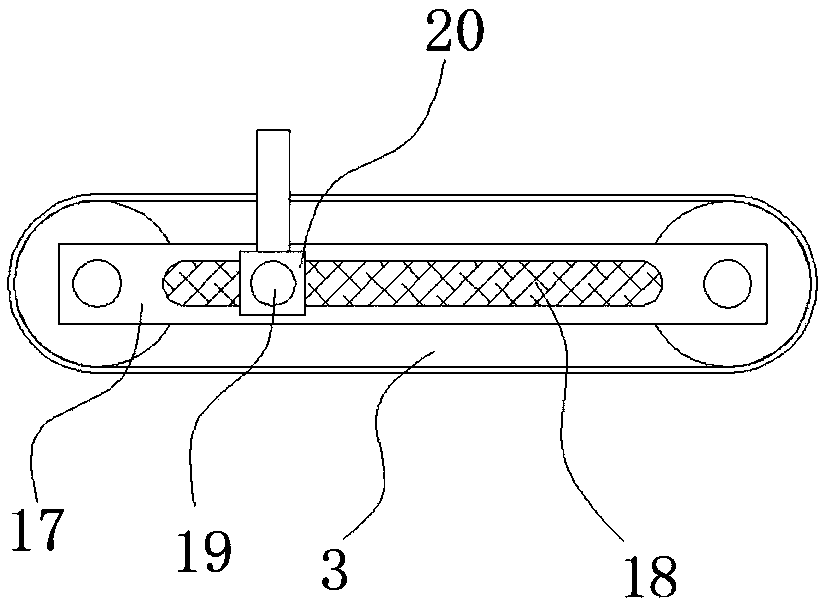

[0029] Embodiment two, when winding, first manually press one end of the fabric figure 1 Wrap it around the reel as shown and wind it around once, then press the two switches on the left side to make the conveyor belt 3 start to rotate clockwise. Slide back and forth to the right and then to the left, and at the same time, the rotating motor starts to drive the fixed shaft 6 to rotate clockwise. The hole is limited to only rotate horizontally, and will not shake due to the connecting block. The fixed shaft 6 drives the second limiting wheel 4 to rotate clockwise. The second limiting wheel 4 is close to the winding drum, and the fixed shaft 6 It is also inserted in the through hole in the middle of the winding drum, so that under the action of the fixed shaft 6 and the second limit wheel 4, the winding drum is driven to rotate clockwise together, and the winding drum continuously tears the fabric from the fabric roll. The roulette groove 13 of the roulette 12 passes through th...

Embodiment 3

[0030] Embodiment 3, when the reel is replaced, when the reel is full of fabrics, press the two switches on the most side to suspend the work of the conveyor belt 3, the sliding bolt 19 and the fixed shaft 6, open the right side baffle and use scissors to Cut the fabric, and stick the fabric on the winding drum with adhesive tape, then press the switch on the right side, so that the drive motor drives the drive blocks 11 on both sides to slide to both sides along the slide bar, and the drive block 11 drives the connecting rod 10 to Moving outward, the connecting rod 10 drives the linkage rod 8 to pull the first mounting block 7 outwards, and the first mounting block 7 drives the fixed shaft 6 through the connecting block to draw out of the middle through hole of the reel, when the driving blocks 11 on both sides respectively When sliding to the two ends of the slide bar, press the switch to pause, at this time the fixed shafts 6 on both sides are also pulled away from the reel,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com