Efficient mixing system for well cementing operation

A mixing system and cementing technology, which is applied to wellbore/well components, control devices, liquid batching supply devices, etc., can solve the problems of low operation efficiency, small mixing displacement, and inability to achieve continuous operation, and achieve convenient and practical operation. , Overcome the effect of reduced mixing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

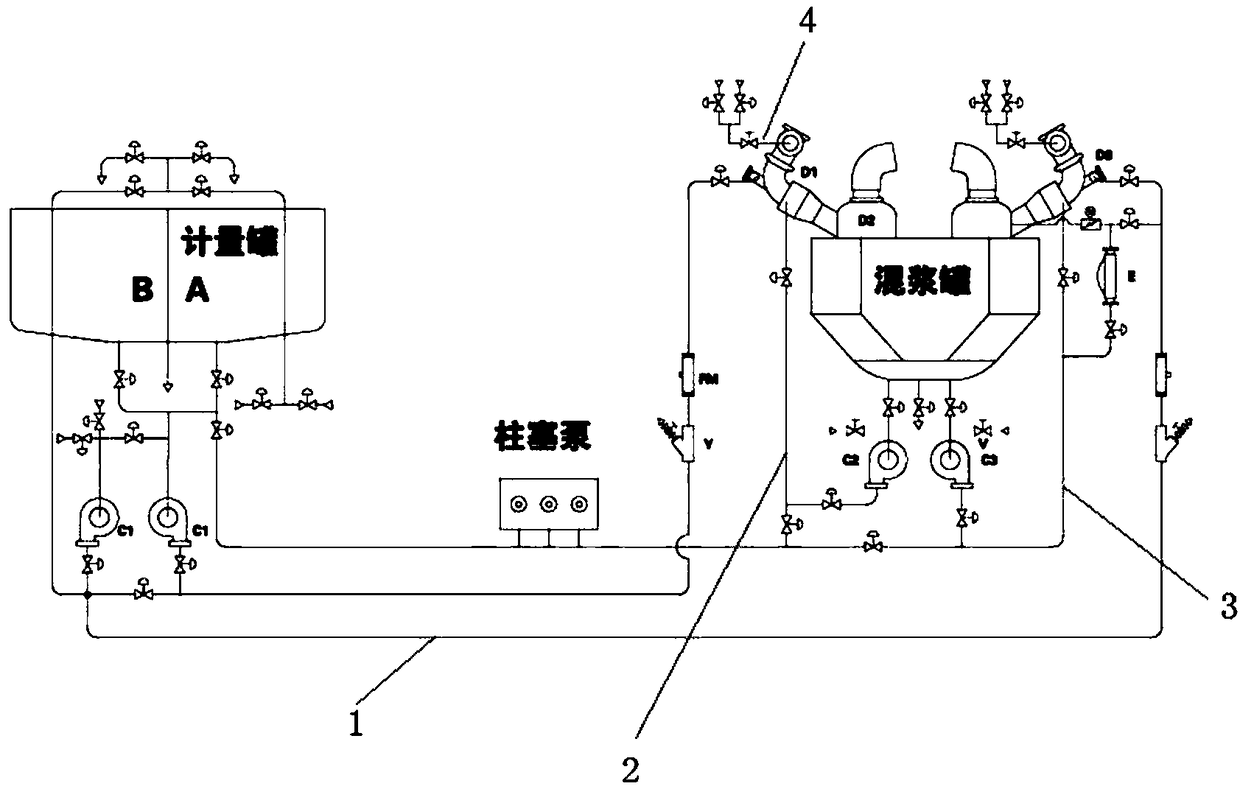

[0026] Such as figure 2 As shown, a mixing system for high-efficiency well cementing operations includes metering tanks, clean water pipes combined into 1, ash loading pipes combined into 4, high-energy mixer D3, mud mixing tanks and mud pipes combined into 3, and the mixing tanks are connected with Two high-energy mixers D3, the entrance of the mixing tank is connected to the diffusion box D2, the diffusion box D2 is connected to the high-energy mixer D3, the output of the high-energy mixer D3 is imported into the mixing tank from the diffusion box D2, and the mud pipes are aggregated into 3 Connect the density control system E in series. There are two diffusion boxes.

[0027] The clean water pipes are aggregated into 1 and equipped with a jet centrifugal pump C1, a Y-shaped filter Y and a clean water flow meter FM. The clean water flow meter FM can display the flow of clean water. According to the displayed clean water flow, the flow can be adjusted according to the desig...

Embodiment 2

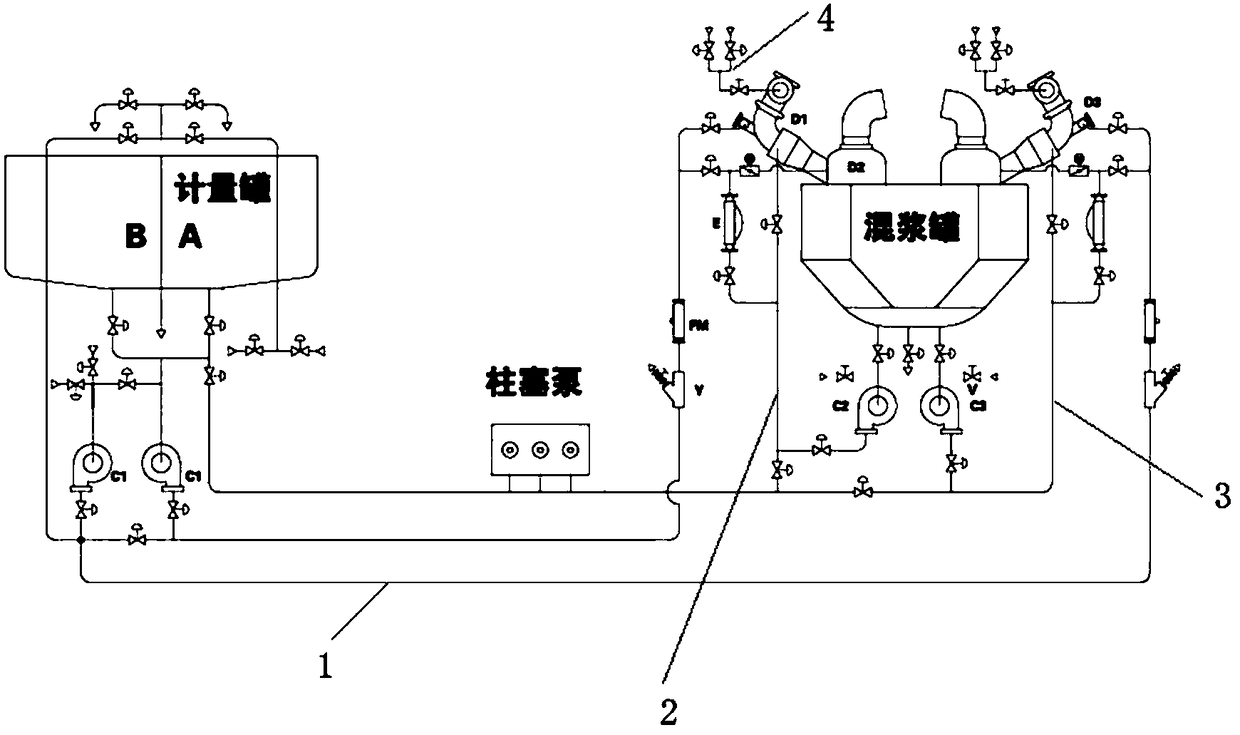

[0034] like image 3 As shown, a mixing system for high-efficiency well cementing operations includes metering tanks, clean water pipes combined into 1, ash loading pipes combined into 4, high-energy mixer D3, mud mixing tanks and mud pipes combined into 3, and the mixing tanks are connected with Two high-energy mixers D3, the entrance of the mixing tank is connected to the diffusion box D2, the diffusion box D2 is connected to the high-energy mixer D3, the output of the high-energy mixer D3 is imported into the mixing tank from the diffusion box D2, and the circulation manifold 2 and the mud pipe are combined into 3, which are all connected in series with a density control system E, and there are two diffusion boxes.

[0035] The clean water pipes are aggregated into 1 and equipped with a jet centrifugal pump C1, a Y-shaped filter Y and a clean water flow meter FM. The clean water flow meter FM can display the flow of clean water. According to the displayed clean water flow, ...

Embodiment 3

[0042] like Figure 4 As shown, a mixing system for high-efficiency well cementing operations includes metering tanks, clean water pipes combined into 1, ash loading pipes combined into 4, high-energy mixer D3, mud mixing tanks and mud pipes combined into 3, and the mixing tanks are connected with Two high-energy mixers D3, the entrance of the mixing tank is connected to the diffusion box D2, the diffusion box D2 is connected to the high-energy mixer D3, the output of the high-energy mixer D3 is imported into the mixing tank from the diffusion box D2, and the mud pipes are aggregated into 3 Connect the density control system E in series. The diffusion box is one.

[0043] The clean water pipes are aggregated into 1 and equipped with a jet centrifugal pump C1, a Y-shaped filter Y and a clean water flow meter FM. The clean water flow meter FM can display the flow of clean water. According to the displayed clean water flow, the flow can be adjusted according to the design requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com