Device and method for hydraulically measuring concrete demoulding performance

A technology for demoulding performance and concrete, which is applied in the field of hydraulic measuring devices for concrete demoulding performance, can solve the problems of inability to realize precise control and monitoring of air pressure changes, time-consuming and labor-intensive operations, complex equipment and cost, etc., to save time and energy, Overcoming expensive equipment and improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

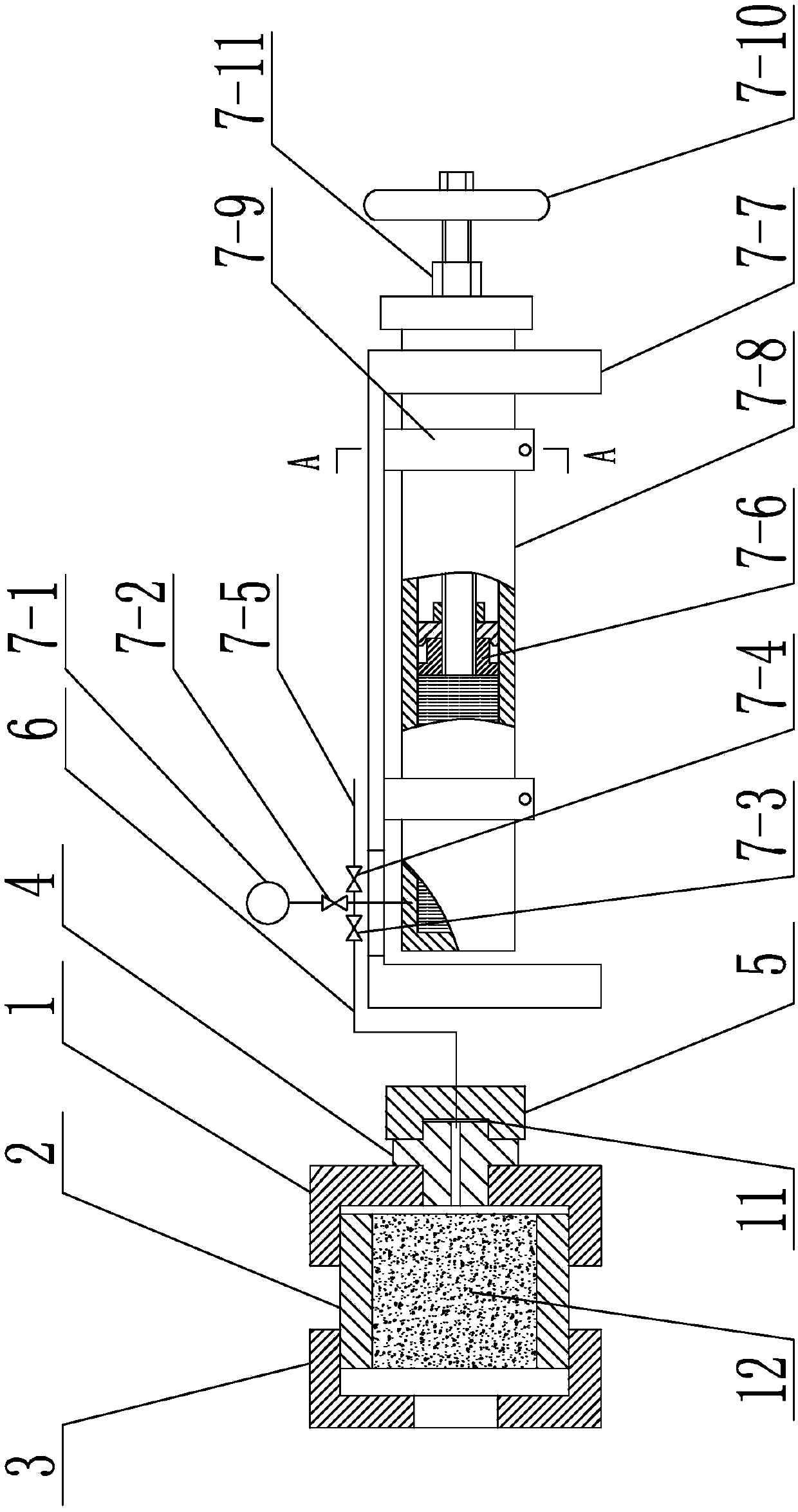

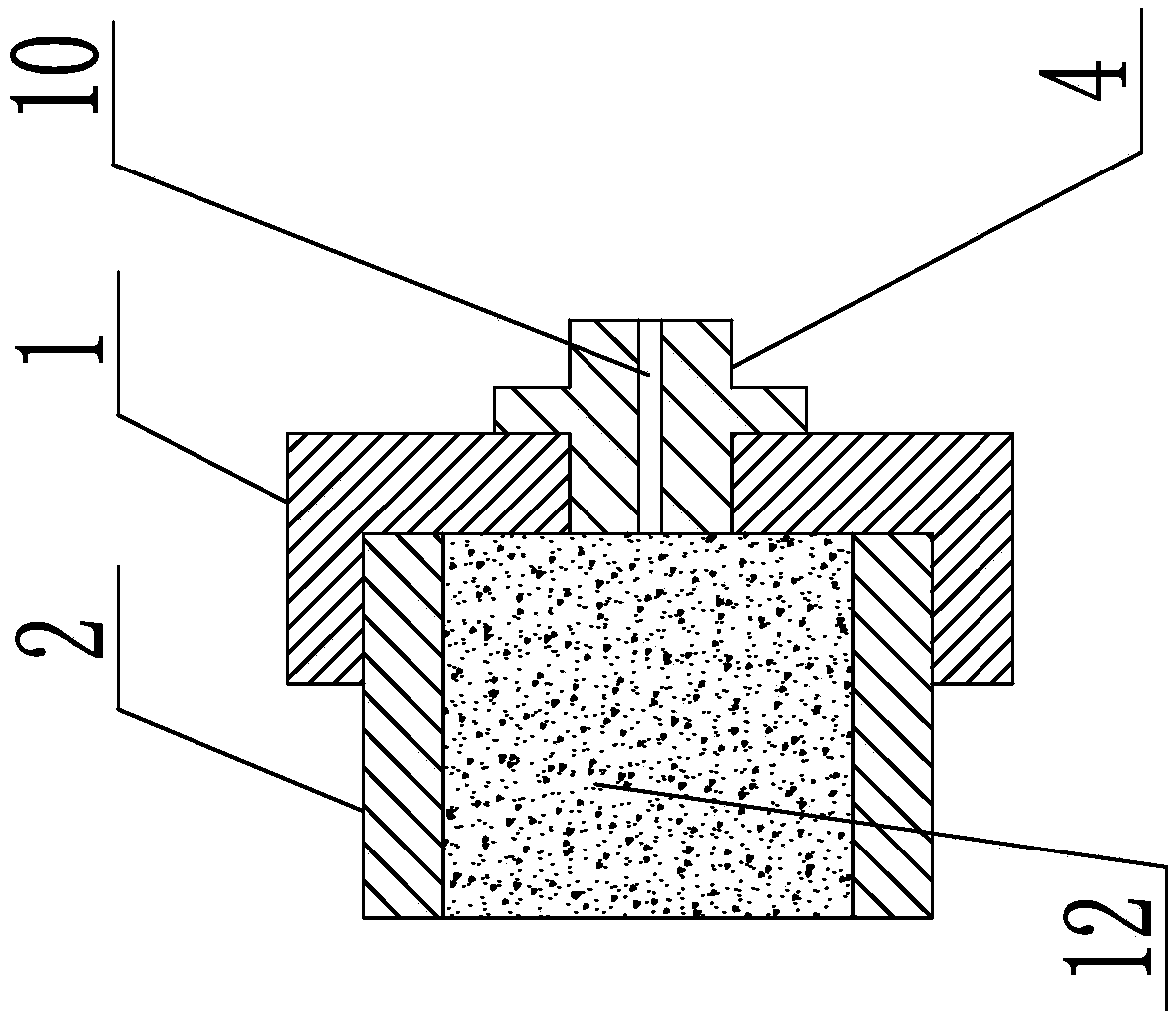

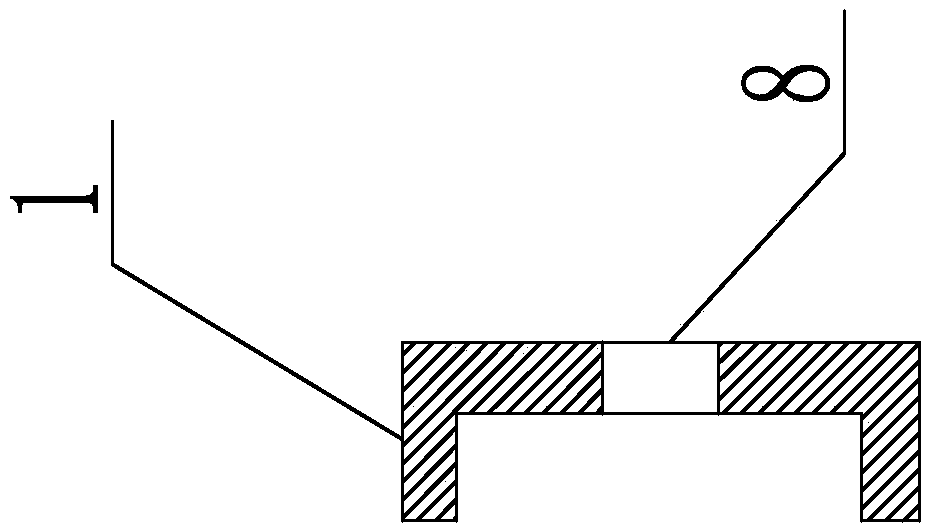

[0028] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5Describe this embodiment, this embodiment includes first installation cover 1, concrete mold 2, second installation cover 3, middle piece 4, connecting pipe 6 and hydraulic pump, described first installation cover 1 and second installation cover 3 vertical Arranged side by side, the concrete mold 2 is arranged between the first installation cover 1 and the second installation cover 3, the two ends of the concrete mold 2 are detachably connected with the first installation cover 1 and the second installation cover 3 respectively, the concrete mold 2 is provided with concrete 12, one end of the middle piece 4 passes through the first installation cover 1 and communicates with the concrete 12 in the concrete mold 2, and the other end of the middle piece 4 communicates with the oil outlet of the hydraulic pump through the connecting pipe 6.

[0029] Adding the second insta...

specific Embodiment approach 2

[0035] Specific implementation mode two: combination figure 1 , figure 2 and image 3 To illustrate this embodiment, first place the concrete mold 2 vertically, screw its lower end with the first installation cover 1, and connect the internal thread of the first through hole 8 with the external thread of the middle piece 4, and assemble the concrete mold 2 Add a layer of plastic film to the bottom of the concrete mold 2, apply a release agent on the inner wall of the concrete mold 2, then fill the concrete mold 2 with fresh concrete 12 that meets the requirements of the standard, and place it under standard curing conditions for at least 24 hours of maintenance; After completion, after the upper end of the concrete mold 2 is screwed to the second installation cover 3, the concrete test mold 2 is placed horizontally, and the first installation cover 1 is unscrewed so that the distance between the first installation cover 1 and the lower end of the concrete mold 2 is 5 ~ 10mm...

Embodiment 1

[0038] Embodiment one: the concrete mold 2 is a steel pipe, its inner diameter is 200mm, the radius R=100mm, the height H is 200mm, and the diameter of the first through hole 8 is 50mm. First, the concrete mold 2 is vertically placed, and its lower end is connected with the first installation The cover 1 is threaded, the internal thread of the first through hole 8 is connected with the external thread of the middle piece 4, and a layer of plastic film is added to the bottom of the assembled concrete mold 2 to ensure that the concrete 12 does not enter the first hole in the middle piece 4. A through hole 10 and isolation concrete 12 are in contact with the first installation cover on the end face, then apply a release agent on the inner wall of the concrete mold 2, then fill the concrete mold 2 with fresh concrete 12 that meets the requirements of the standard, and place the Curing under standard curing conditions for at least 24 hours; after the curing is completed, the upper e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com