A sensor capable of reducing errors and its measuring method

A sensor and error technology, applied in the field of sensors, can solve the problems of difficulty in determining whether the voltage signal corresponds to the real pressure value, the incomplete coincidence of the loading line and the unloading line, and the low accuracy of the pressure signal, so as to avoid uncertain problems and have a simple structure. , the effect of a large measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

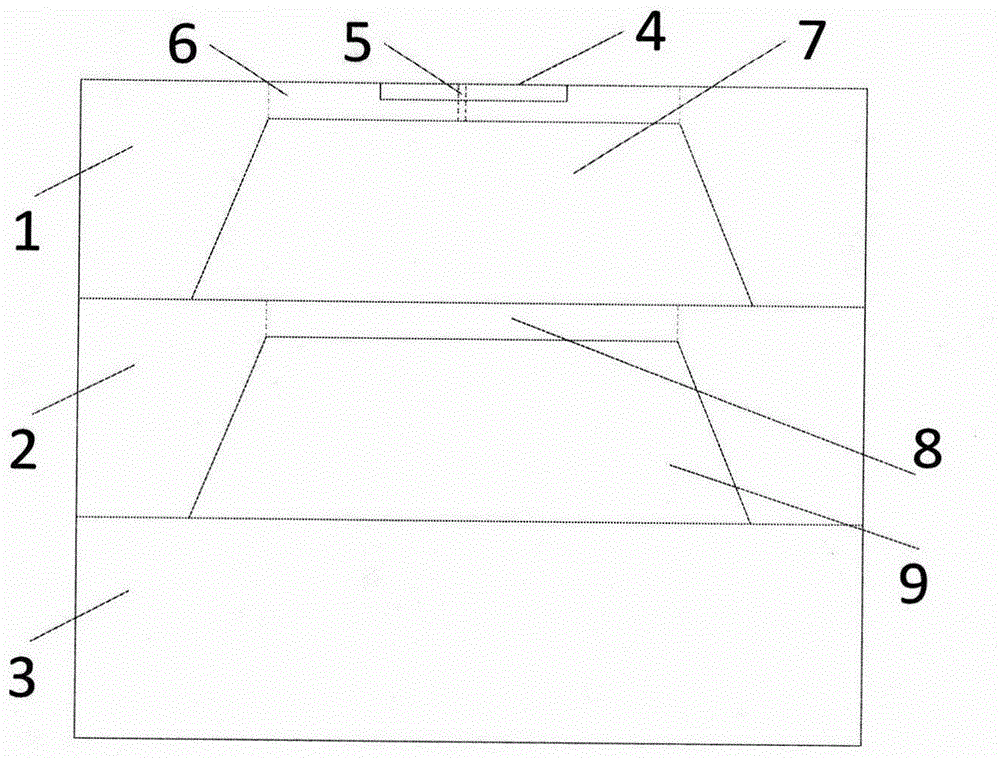

[0009] Control attached figure 1 , the sensor consists of a first substrate 1, a second substrate 2, a third substrate 3, a heating resistor 4, a through hole 5, a diaphragm 6 of the first substrate, a cavity 7 of the first substrate, a diaphragm 8 of the second substrate, The cavity 9 of the second substrate is formed. Wherein the first substrate 1 is connected with the second substrate 2, the second substrate 2 is connected with the third substrate 3, the cavity 9 of the second substrate is located at the junction of the second substrate 2 and the third substrate 3, and the cavity is a closed vacuum Cavity: The cavity 7 of the first substrate is located at the junction of the first substrate 1 and the second substrate 2, and the through hole 5 connects the gas in the cavity 7 of the first substrate with the outside air.

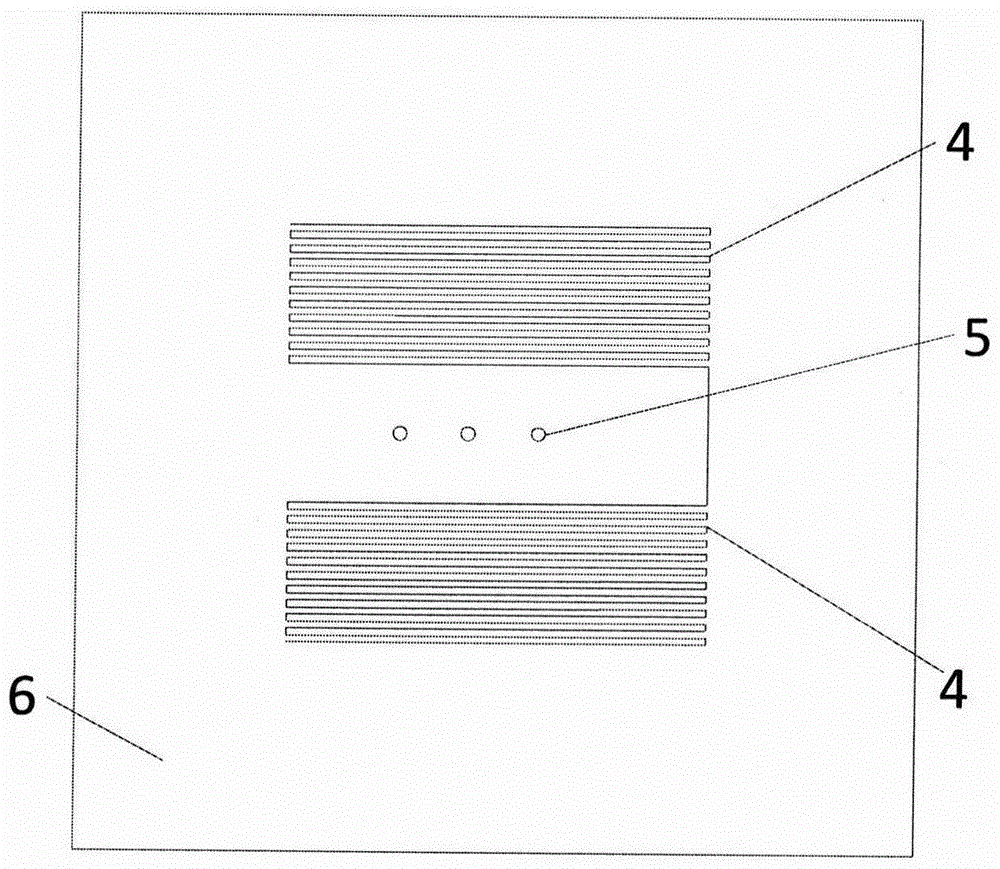

[0010] control figure 2 The diaphragm 6 of the first substrate has a heating resistor 4 and a through hole 5, and the heating resistor 4 is placed at bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com