Rock microwave fracturing testing device based on true triaxial loading

A test device and true three-axis technology, applied in microwave heating, instruments, teaching models, etc., can solve the problems of affecting construction progress, increasing construction costs, and consuming single-knife cutter rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

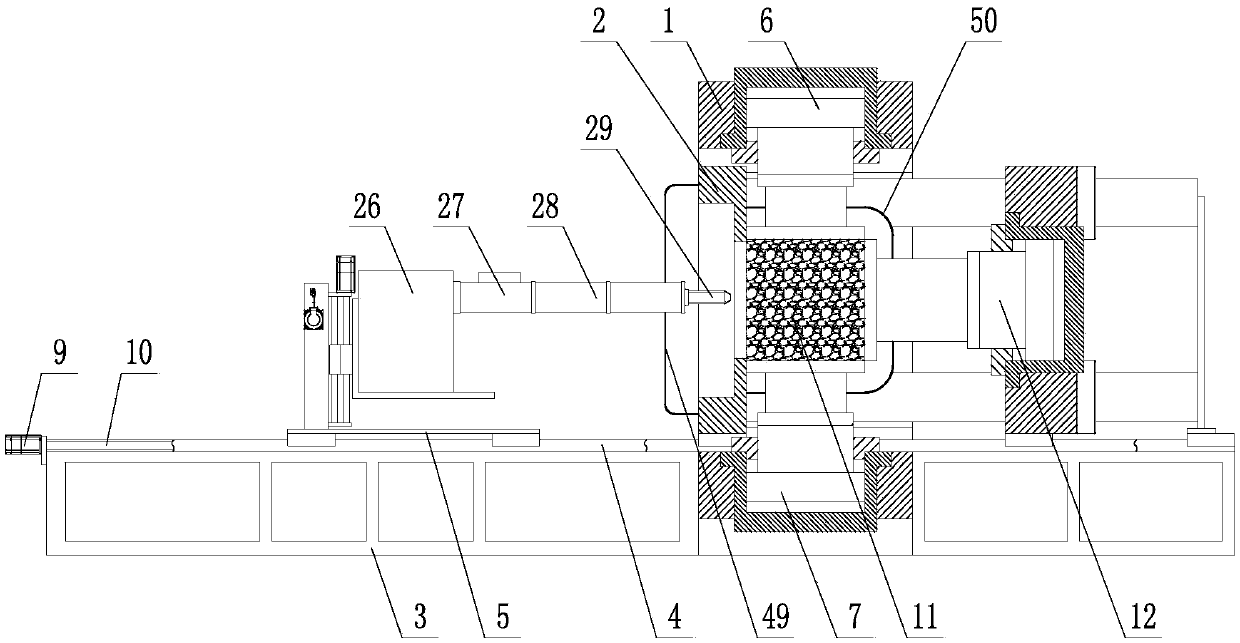

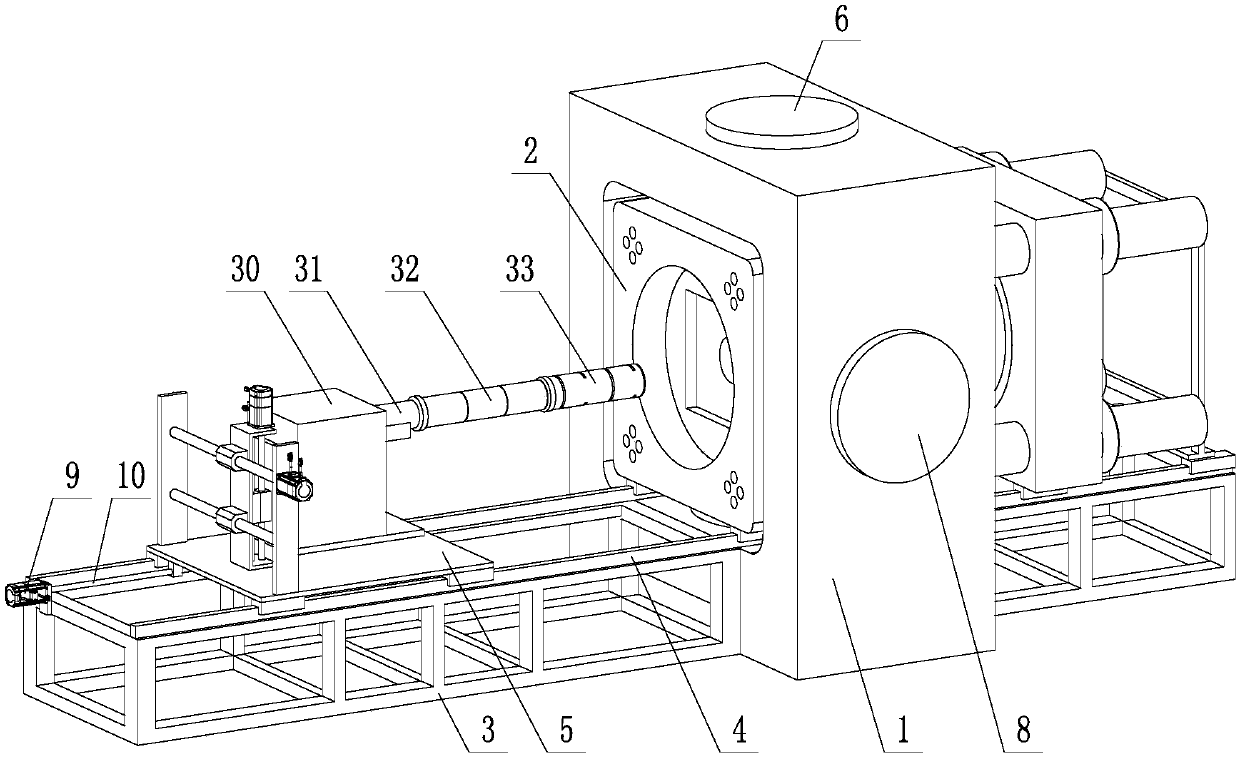

[0038] Such as Figure 1-13 As shown, a rock microwave fracturing test device based on true triaxial loading includes a true triaxial loading assembly and a microwave radiation fracturing assembly; the true triaxial loading assembly includes a fixed loading frame 1 and a movable loading frame 2 , base 3, track 4, slide table 5 and two-degree-of-freedom mobile frame; the fixed loading frame 1 adopts a square structure, and the middle space of the fixed loading frame 1 is a rock sample loading cavity; The fixed loading frame 1 directly above the sample loading chamber is provided with a first Z-direction actuator 6, and the fixed loading frame 1 directly below the rock sample loading chamber is provided with a second Z-direction actuator 7. The fixed loading frame 1 on the left side of the rock sample loading chamber is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com