Articulated self-propelled raise-boring machine

A raise drilling rig, self-propelled technology, applied in rotary drilling rig, impact drilling, rotary drilling and other directions, can solve the problems of affecting drilling accuracy, high requirements for underground tunnels, large turning radius, etc. Hole accuracy, improve ground passability, and reduce the effect of turning radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

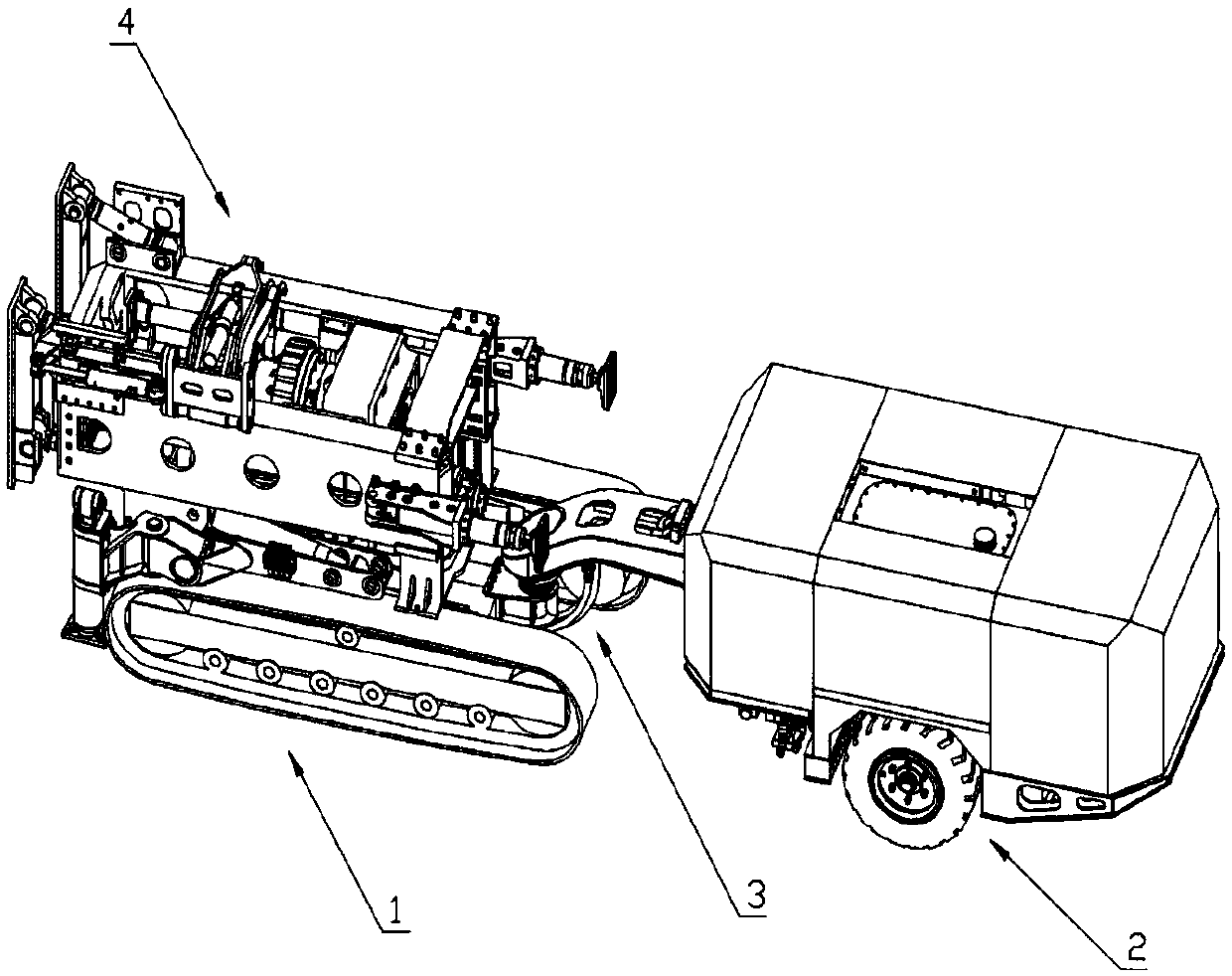

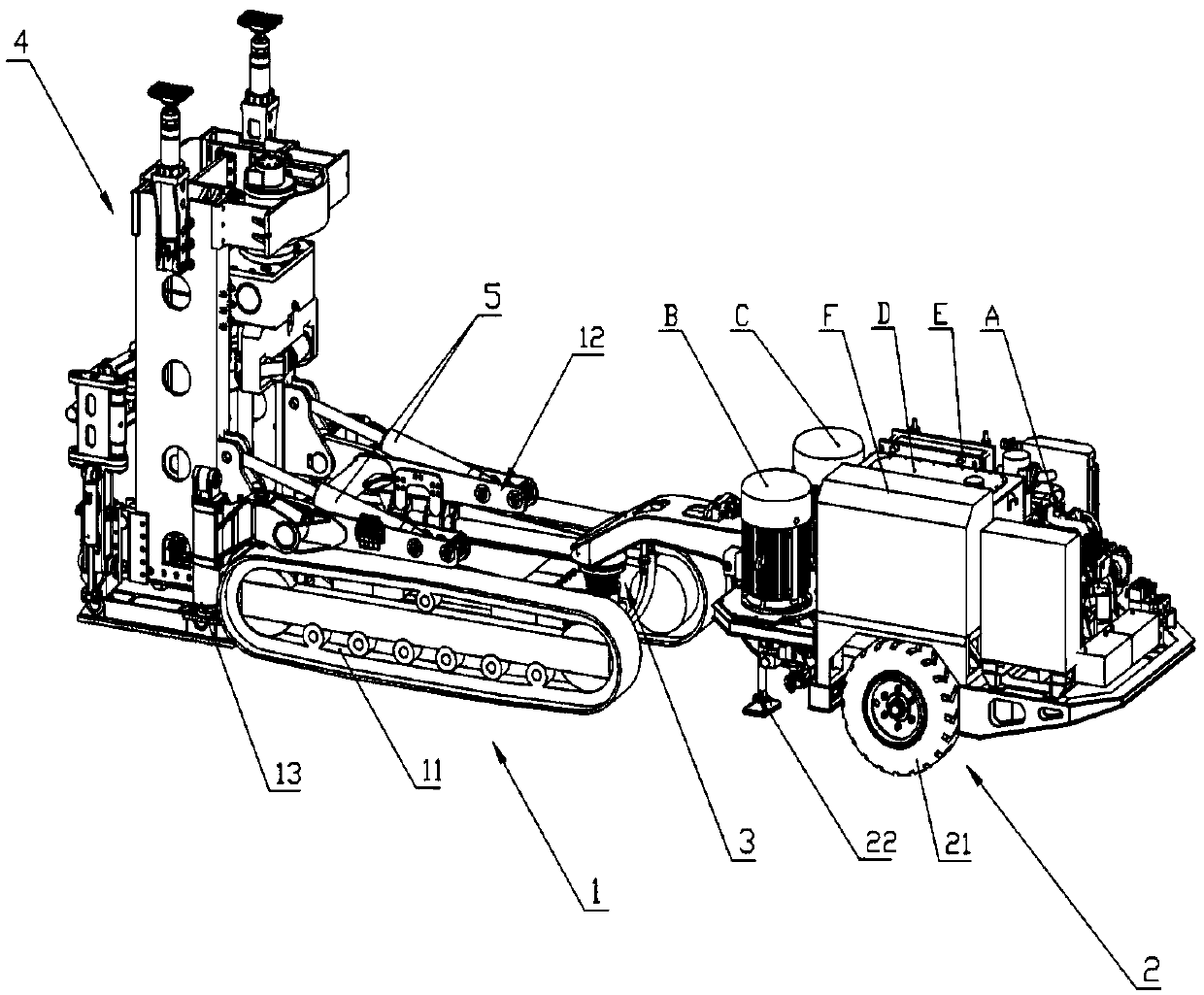

[0037] Such as figure 1 , figure 2 As shown, the articulated self-propelled raise drilling rig provided in this embodiment includes a front frame 1 , a rear frame 2 , a floating hinge mechanism 3 and a main engine assembly 4 .

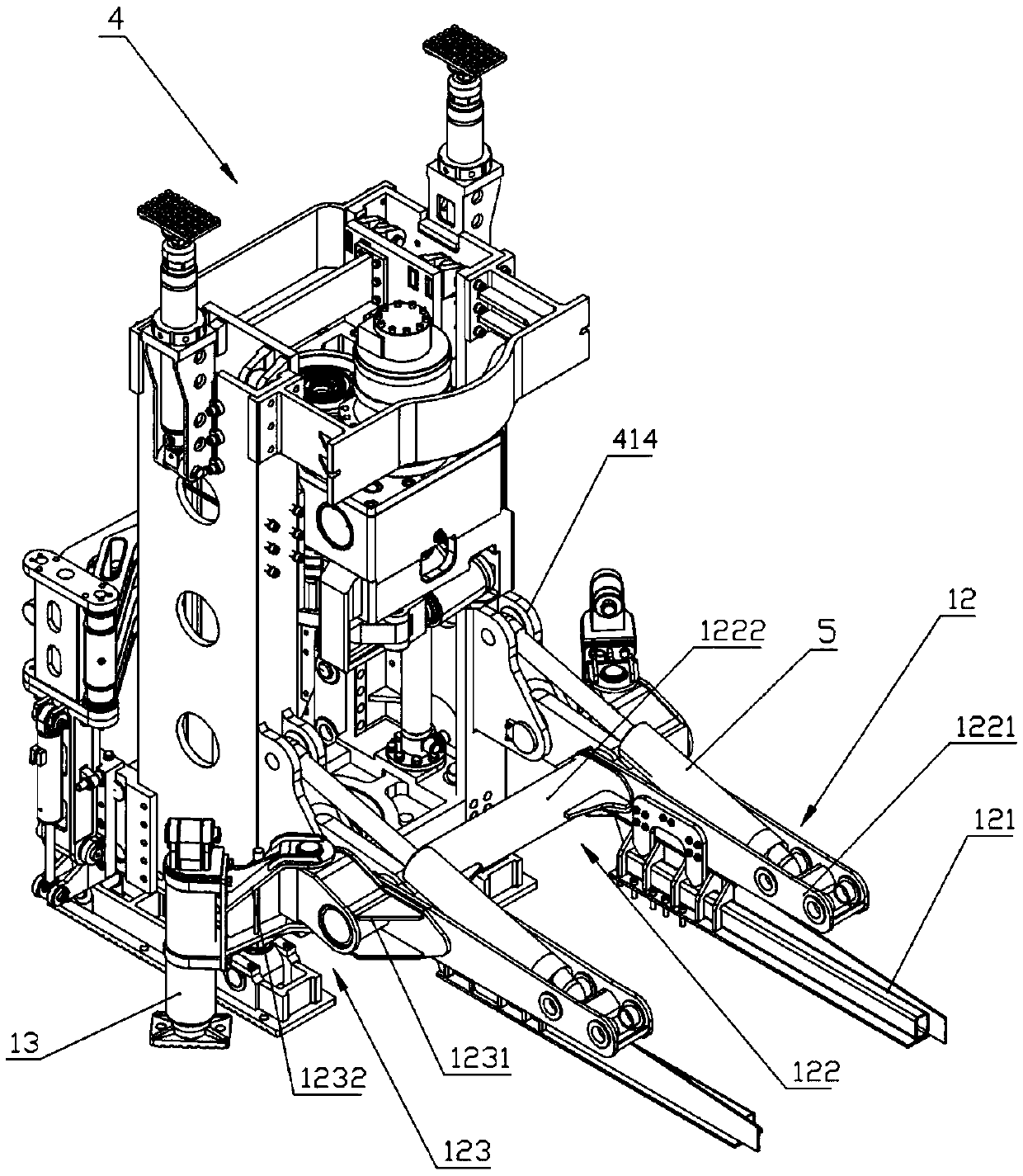

[0038] The front frame 1 includes a crawler chassis 11 , a floating frame 12 and a front leg 13 .

[0039] Such as image 3 , Figure 4As shown, the floating frame 12 includes a base frame 121 , a suspension beam frame 122 and a leg mounting assembly 123 . Underframe 121 has a pair, is symmetrically arranged on it with respect to the center plane of the width direction of crawler chassis 11; Suspension beam frame 122 comprises a pair of suspension beams 1221 that are arranged directly above the underframe and the strengthening beam 1222 that connects two suspension beams as a whole, suspension beam It includes a pair of side plates and a center plate; one end of the center plate is provided with a hinge hole, the hinge hole is a long hole, the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com