Sound-proof building board

A technology for building panels and sound insulation layers, applied in the field of building panels, can solve the problems of poor sound insulation effect, high construction strength, no sound insulation and fireproof wall panels, etc., and achieve the effects of prolonging service life, improving stability and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

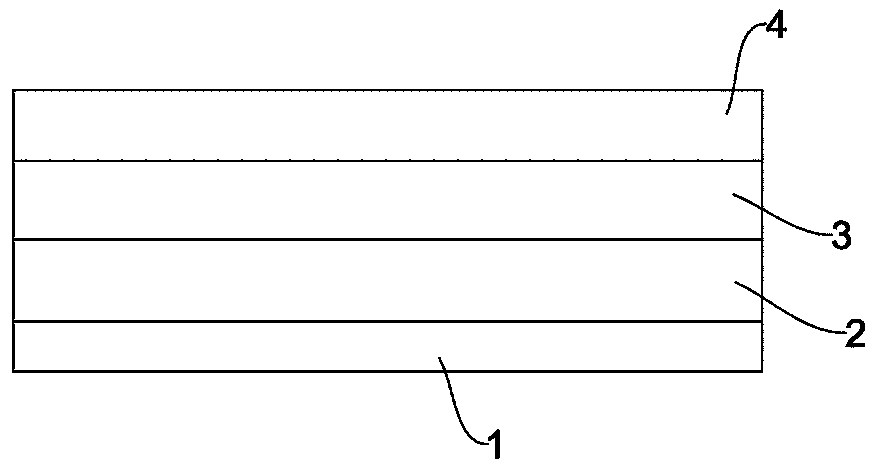

[0027] Such as Figures 1 to 4 The shown sound-insulating building board includes a substrate layer 1 , a first sound-insulating layer 2 , a second sound-insulating layer 3 and a panel layer 4 sequentially from inside to outside. In the present invention, the panel layer is coated with a waterproof and wear-resistant coating.

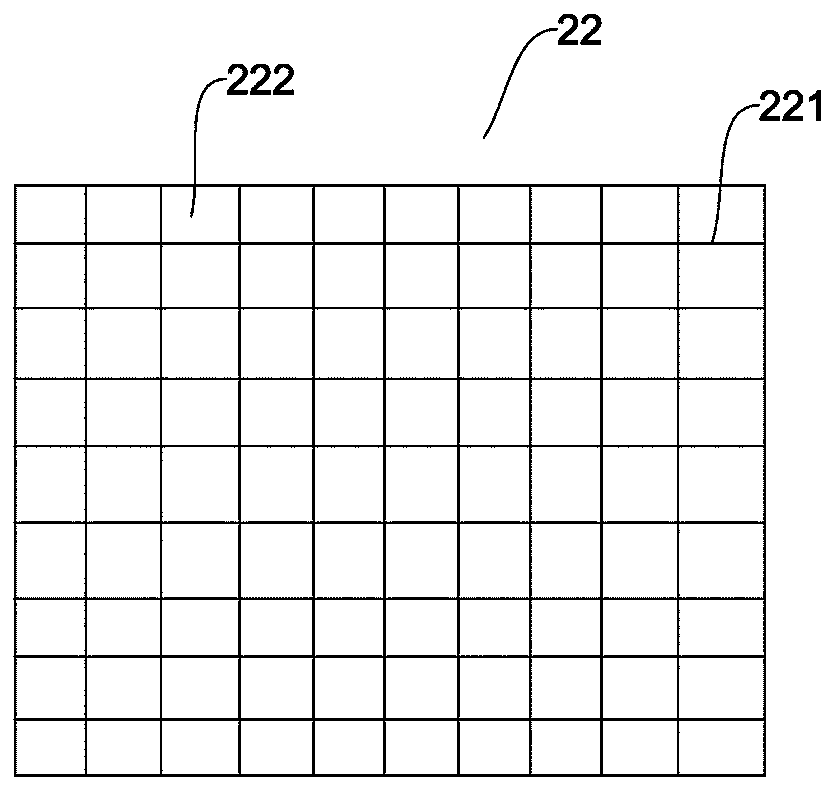

[0028] The first sound insulation layer 2 sequentially includes the first sound insulation cotton layer 21, the glass fiber mesh cloth layer 22 and the second sound insulation cotton layer 23 which are closely attached from the inside to the outside. The design of the first sound insulation layer, on the one hand, the first sound insulation The cotton layer and the second sound-insulating cotton layer have the function of heat insulation, and the glass fiber mesh cloth layer has the function of heat preservation, so that the alternation of cold and heat inside and outside can be reduced. In winter, the indoor heat is not easy to go out; in summer, the ...

Embodiment 2

[0033] Such as figure 1 , 3 , 6, 7 shows a kind of sound insulation building board, which includes substrate layer 1, first sound insulation layer 2, second sound insulation layer 3 and panel layer 4 in order from inside to outside. In the present invention, the panel layer is coated with a waterproof and wear-resistant coating. The difference from Example 1 is:

[0034] The sides of the first sound-insulating cotton layer 21 and the second sound-insulating cotton layer 23 close to the glass fiber mesh layer 22 form a plurality of protrusions 5 toward the glass fiber mesh layer 22, and the protrusions 5 can be inserted into corresponding hollow parts. 222. On the one hand, the protrusions are placed in the hollowed out part and fit together, which can strengthen the strength of the glass fiber mesh cloth layer to a certain extent, and improve the strength of the first sound insulation cotton layer; In the case of the sound insulation quality of the sound insulation cotton,...

Embodiment 3

[0038] Embodiment 3: as image 3 , 5 A sound-insulating building board shown in 7 includes a substrate layer 1 , a first sound-insulating layer 2 , a second sound-insulating layer 3 and a panel layer 4 sequentially from inside to outside. In the present invention, the panel layer is coated with a waterproof and wear-resistant coating. The difference from Example 2 is:

[0039] The hollow part 222 is provided with sound-insulating filling particles. When producing the first sound insulation layer, first cover the glass fiber mesh cloth layer on the first sound insulation cotton layer or the second sound insulation cotton layer, and then fill the hollow part with some porous sound insulation filling particles, such as ceramics and bentonite, and then cover Another layer of sound-proof cotton is pressed to form the first sound-proof layer. This operation can further improve the effect of sound insulation, and also improve the thermal insulation effect of the glass fiber mesh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com