Temporary prestressing device for segment prefabricated assembled beam

A prefabricated and prestressed technology, applied in the field of bridge structure construction, can solve the problems of inconsistent position of temporary tension pedestals, improper plugging of channels, easy water seepage, etc. The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

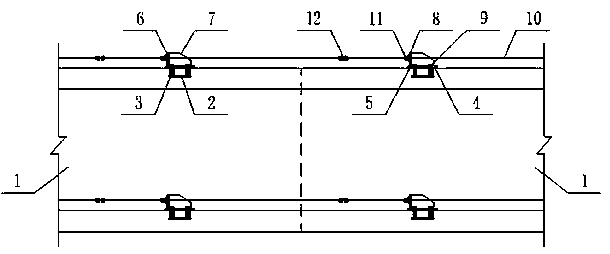

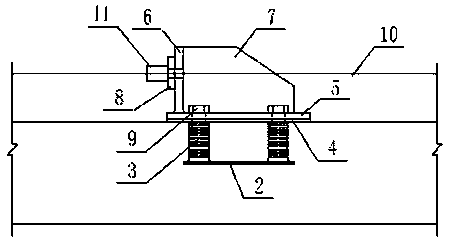

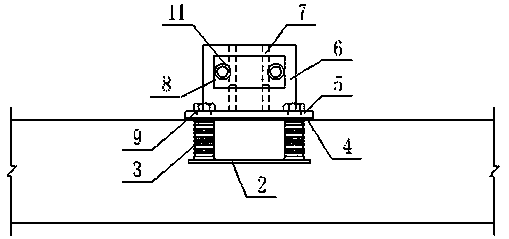

[0031] Such as Figure 1~4 As shown, a temporary prestressing device for segmental prefabricated assembled beams includes adjacent spliced prefabricated segments 1, and the prefabricated segments 1 are provided with temporary tensioning pedestals, and the temporary tensioning pedestals include The anchor plate 6 passes through the temporary prestress 10 , and the temporary prestress 10 is anchored to the anchor plate 6 through nuts 12 .

[0032] A rib 7 is arranged on the back of the anchor plate 6 , and a bottom plate 5 is arranged at the lower ends of the anchor plate 6 and the rib 7 .

[0033] The prefabricated segment 1 is a prefabricated segment of a concrete beam, and a positioning steel plate 2 and a sleeve 3 are pre-embedded in the prefabricated segment 1. A sleeve 3 is arranged on the positioning steel plate 2, and a sleeve 3 is formed in the sleeve 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com