Double-component modified polyether sealant and preparation method thereof

A technology of silane-modified polyether and sealant, which is applied in the field of sealant, can solve the problems of short operation time, long curing cycle of sealant, affecting the construction and use of sealant, etc., to prolong the operation time and shorten the curing cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a method for preparing the two-component modified polyether sealant described in the above technical solution, comprising the following steps:

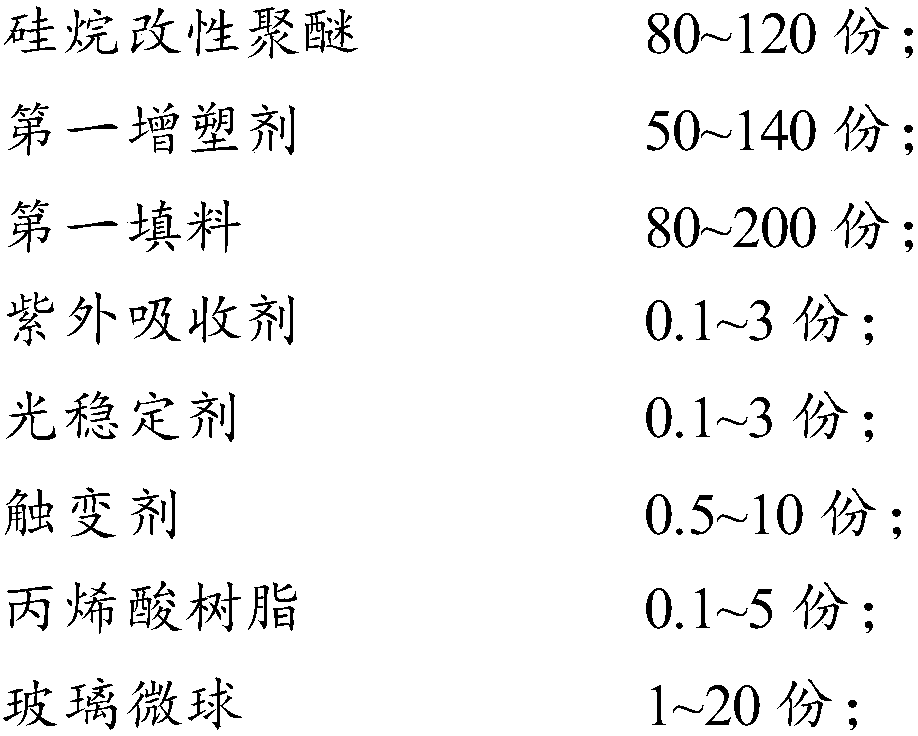

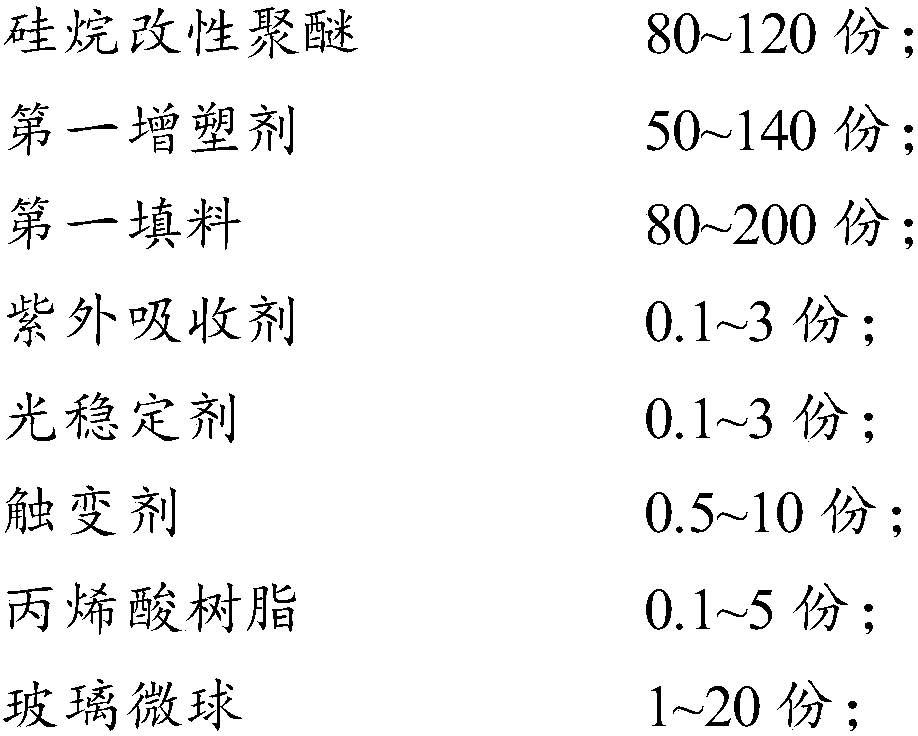

[0060] a) After mixing and heating silane-modified polyether, first plasticizer, first filler, ultraviolet absorber, light stabilizer and thixotropic agent, adding acrylic resin and glass microspheres to obtain material A;

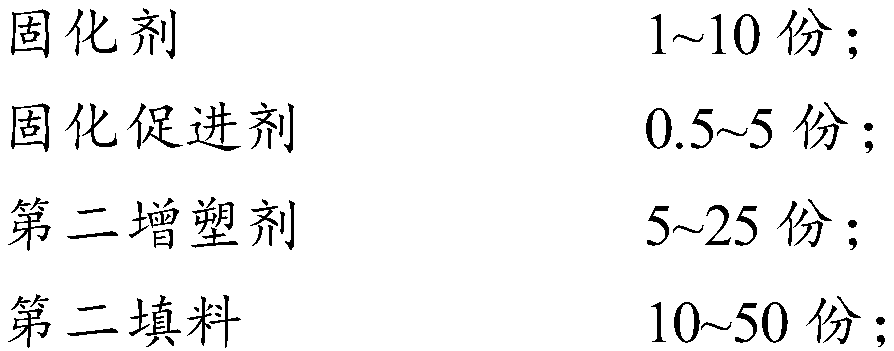

[0061] mixing the curing agent, the curing accelerator, the second plasticizer and the second filler to obtain material B;

[0062] b) Mixing the material A and material B to obtain a sealant.

[0063] Wherein, the silane modified polyether, the first plasticizer, the first filler, the ultraviolet absorber, the light stabilizer, the thixotropic agent, the acrylic resin, the glass microsphere, the curing agent, the curing accelerator, the second plasticizer The type, amount and source of the agent and the second filler are consistent with those described in the above-ment...

Embodiment 1

[0073] Raw materials: 100 parts of silane modified polyether S510H, 100 parts of the first plasticizer diisononyl phthalate, 165 parts of the first filler heavy calcium, 3 parts of ultraviolet absorber UV326, 3 parts of light stabilizer 292, thixotropic 10 parts of polyamide wax, 5 parts of propane trimethylol triacrylate resin, 20 parts of glass microspheres (20-120 μm); 3 parts of curing agent 2-ethylhexanoic acid tin (Ⅱ), curing accelerator triethylene dodeca 0.6 parts of amine, 10 parts of the second plasticizer diisononyl phthalate, and 20 parts of the second filler kaolin.

[0074] Preparation: Put the silane-modified polyether, the first plasticizer, the first filler, the ultraviolet absorber, the light stabilizer and the thixotropic agent into the double planetary mixer and stir evenly, heat it to 70°C for 1 hour, and evacuate to Remove water at -0.09~-0.01MPa, then cool down to 40°C, add resin and glass microspheres, stir evenly under vacuum to obtain material A. Put...

Embodiment 2

[0076] Raw materials: 100 parts of silane-modified polyether S520H, 100 parts of the first plasticizer diisooctyl phthalate, 165 parts of the first filler nano-calcium carbonate (particle size ≤ 120nm), 1 part of ultraviolet absorber UV320, photostable 1 part of agent 765, 3 parts of thixotropic agent hydrogenated castor oil, 3 parts of propane trimethylol triacrylate resin, 10 parts of glass microspheres (20-120 μm); 3 parts of curing agent dibutyltin dilaurate, 12 parts of curing accelerator 0.6 parts of primary alkyl amine, 6.4 parts of the second plasticizer di-isooctyl phthalate, and 20 parts of the second filler heavy calcium.

[0077] Preparation: Put the silane-modified polyether, the first plasticizer, the first filler, the ultraviolet absorber, the light stabilizer and the thixotropic agent into the double planetary mixer, stir evenly, heat to 80°C for 1 hour, and vacuumize to Remove water at -0.09~-0.01MPa, then cool down to 40°C, add resin and glass microspheres, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com