Industrial wastewater purification system for lithium battery

A technology for industrial wastewater and purification systems, applied in multi-stage water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as increasing costs, achieve the effects of preventing pollution, reducing procedures, and strong impact load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

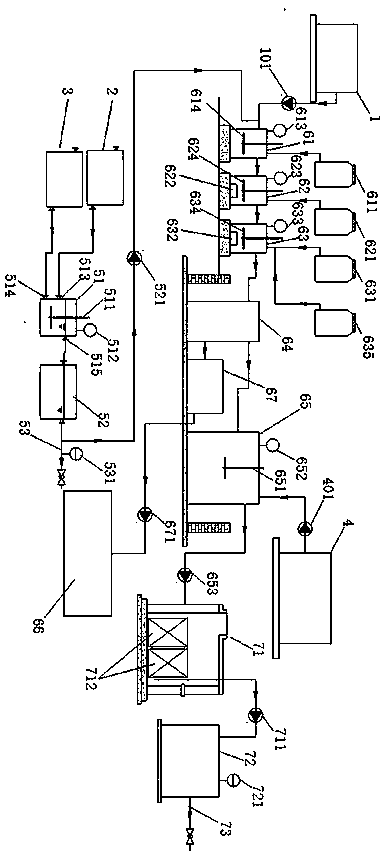

[0035] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0036] Such as figure 1 As shown, a lithium battery industrial wastewater purification system includes an acid-base neutralization unit, a coagulation flocculation sedimentation unit, a facultative membrane biological reaction unit, and a lithium battery production wastewater storage tank 1, an alkaline wastewater storage tank 2, an acidic wastewater storage tank Tank 3, domestic wastewater storage tank 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com