Cutting device for carton production

A cutting device and carton technology, applied in packaging, papermaking, transportation and packaging, etc., can solve the problems of cumbersome installation and disassembly of cutting blades, inconvenient adjustment of cutting distance, and reduced cutting quality, so as to achieve convenient disassembly, replacement and convenient cutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

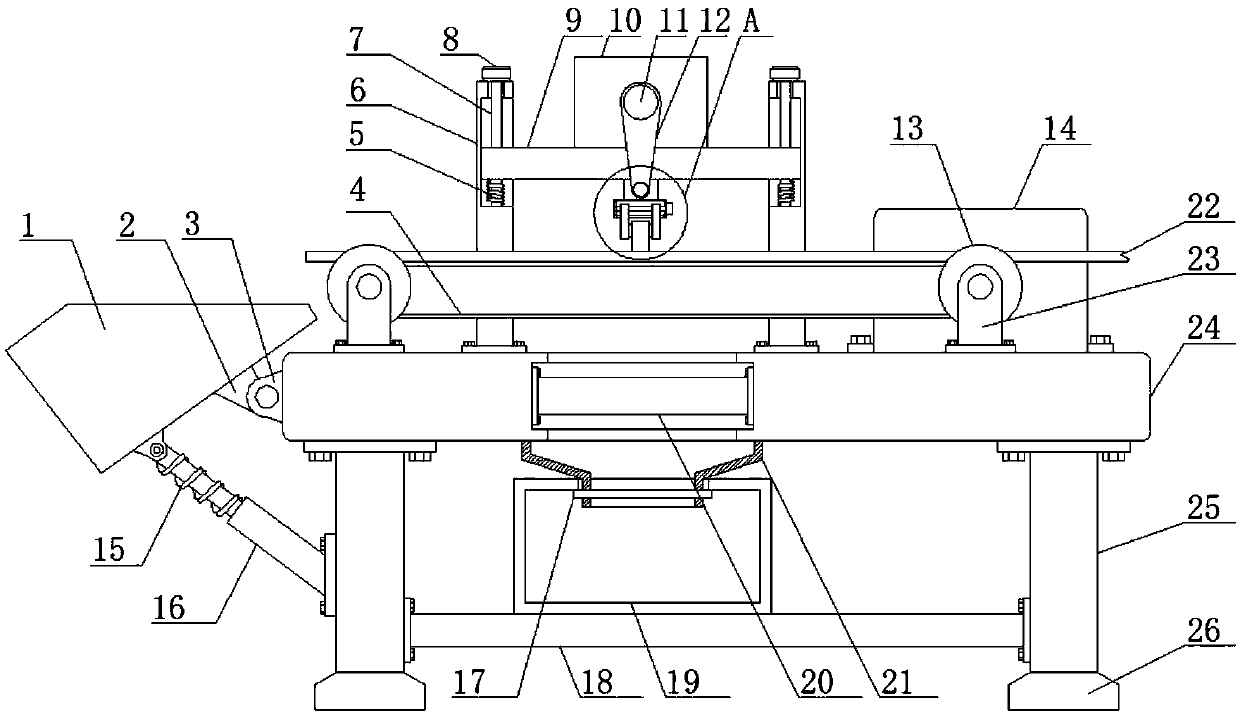

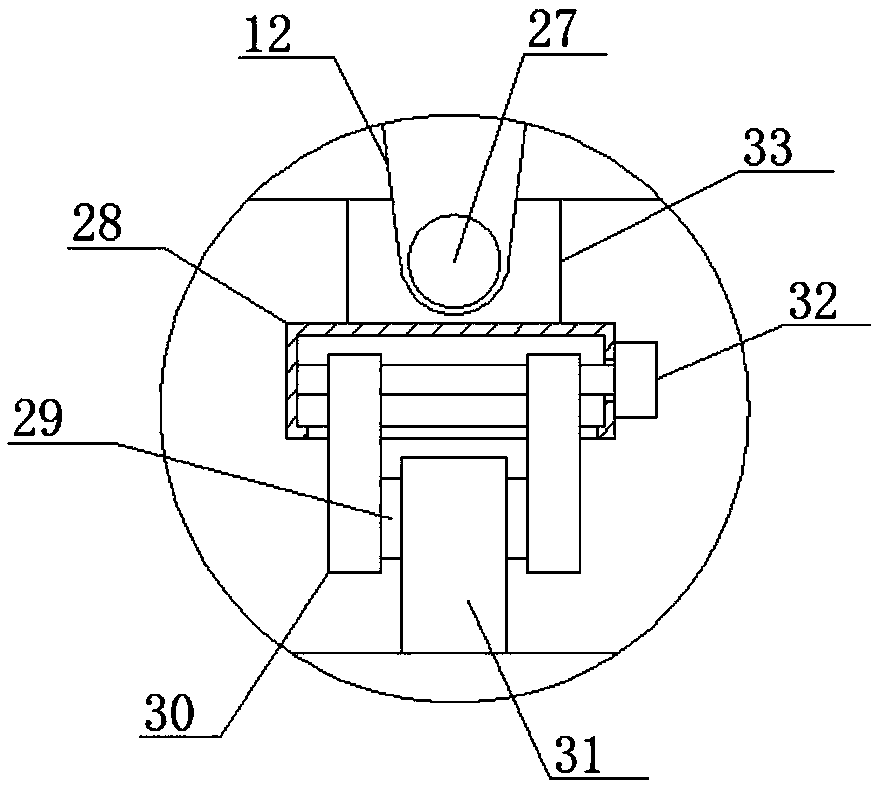

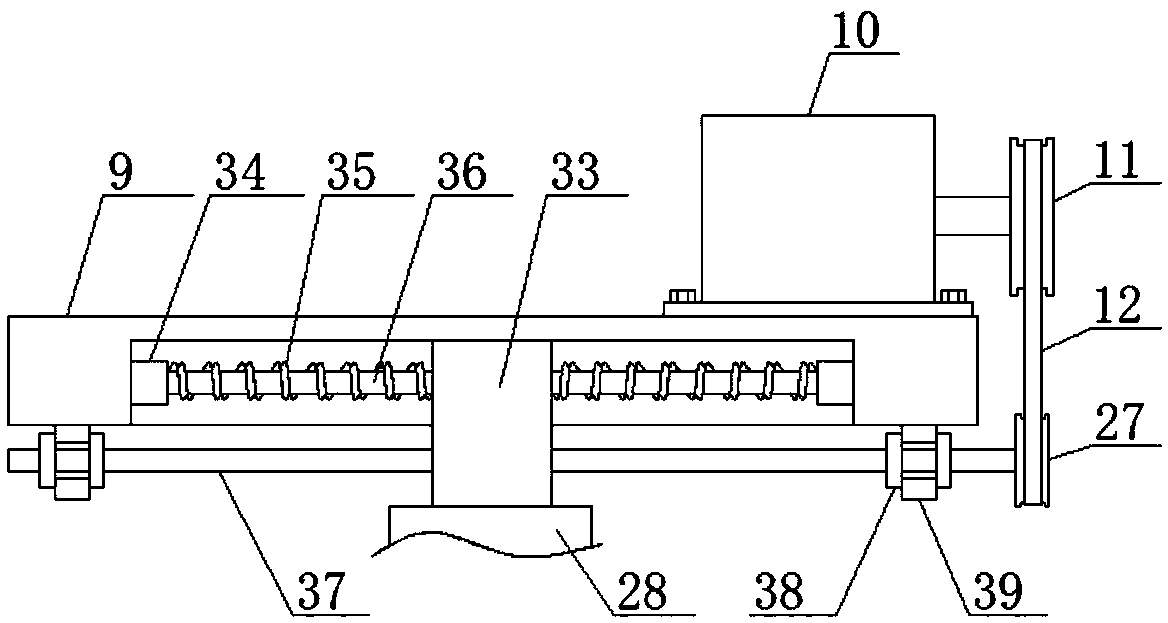

[0030] refer to Figure 1-3 , a cutting device for carton production, including a workbench 24, two support plates 25 are symmetrically fixed on the lower end of the workbench 24, a horizontal plate 18 is fixed between the two support plates 25, and a dust collecting plate is arranged on the upper end of the horizontal plate 18. Case 19, the upper end of dust collection box 19 is communicated with sealing cover 21, and the upper end of sealing cover 21 and the lower end side wall of workbench 24 are offset, and the inside of workbench 24 is provided with storage tank, and turbo fan 20 is fixed in the storage tank, and the work Both sides of the table 24 are provided with openings communicating with the storage slot, and the turbo fan 20 is located directly above the sealing cover 21, and the paper scraps generated in the cutting process are sucked by the turbo fan 20 to absorb the paper scraps and pass through the sealing cover 21. The cover 21 enters the dust collection box 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com