Cleaning and drying and automatic merging equipment for expansion-broken crank connecting rod

A crank connecting rod and breaking technology, which is applied in lighting and heating equipment, cleaning methods using liquid, drying, etc., can solve the problems of low efficiency, disordered sequence of cap end and rod end, and inability to match cap end and rod end and other issues to achieve the effect of improving efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

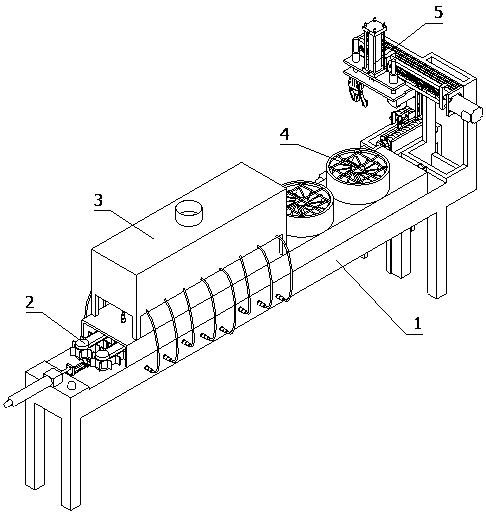

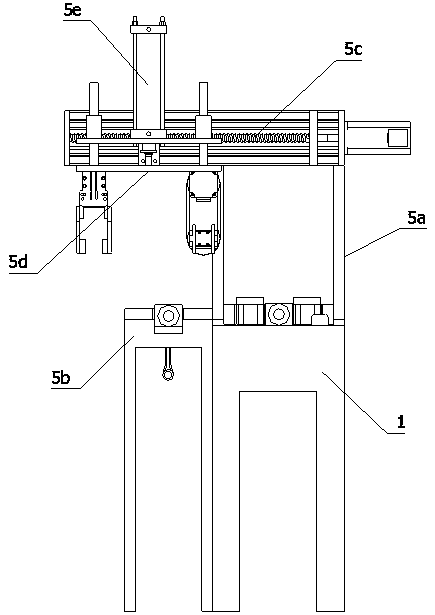

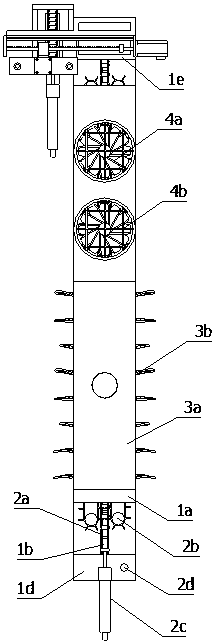

[0023] refer to Figure 1 to Figure 11 It can be seen that the cleaning, drying and automatic merging device for the broken crank connecting rod provided by the present invention includes a table 1 and a transmission device 2 installed on the table 1, a cleaning device 3, a drying device 4 and an automatic merging device 5; The transmission device 2 includes a guide rail 2a distributed along the direction from the head to the tail of the table 1 and used to place the cover end and the rod end of the pop-off crank connecting rod 6, and to drive the cover end and the rod end along the guide rail 2a from The head of the table 1 moves to the driving device 2b at the tail, the cleaning device 3 and the drying device 4 are installed above the head and the tail of the table 1 respectively, and the transmission device 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com