Aviation product production process execution management system

A production process and management system technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve the problems of ineffective segmentation, opaque material management, waste, etc., and achieve the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The aviation product production process execution management system proposed by the present invention will be described in more detail below in conjunction with the schematic diagram, wherein a preferred embodiment of the present invention is shown, it should be understood that those skilled in the art can modify the present invention described here, and still realize the present invention Beneficial effects of the invention. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

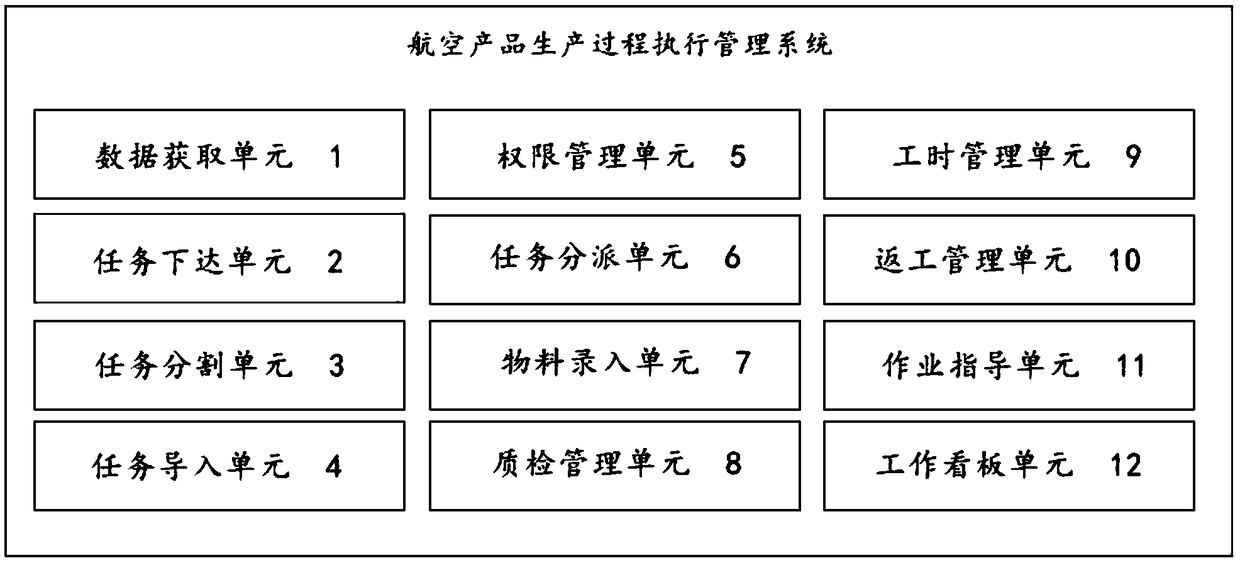

[0026] Such as figure 1 As shown, the aviation product production process execution management system proposed by the present invention can optimize production scheduling, shorten downtime and wait for materials, and can grasp the production status of production work orders on time, provide on-time delivery rate, and provide on-time delivery rate to management and planning layers. Product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com