Quality detection device of seamless steel pipe and detection method

A technology for seamless steel pipes and detection devices, which is applied to measurement devices, optical devices, optical testing of flaws/defects, etc., can solve the problems of difficult algorithm maintenance and high hardware costs, and achieve high precision, high detection speed and detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

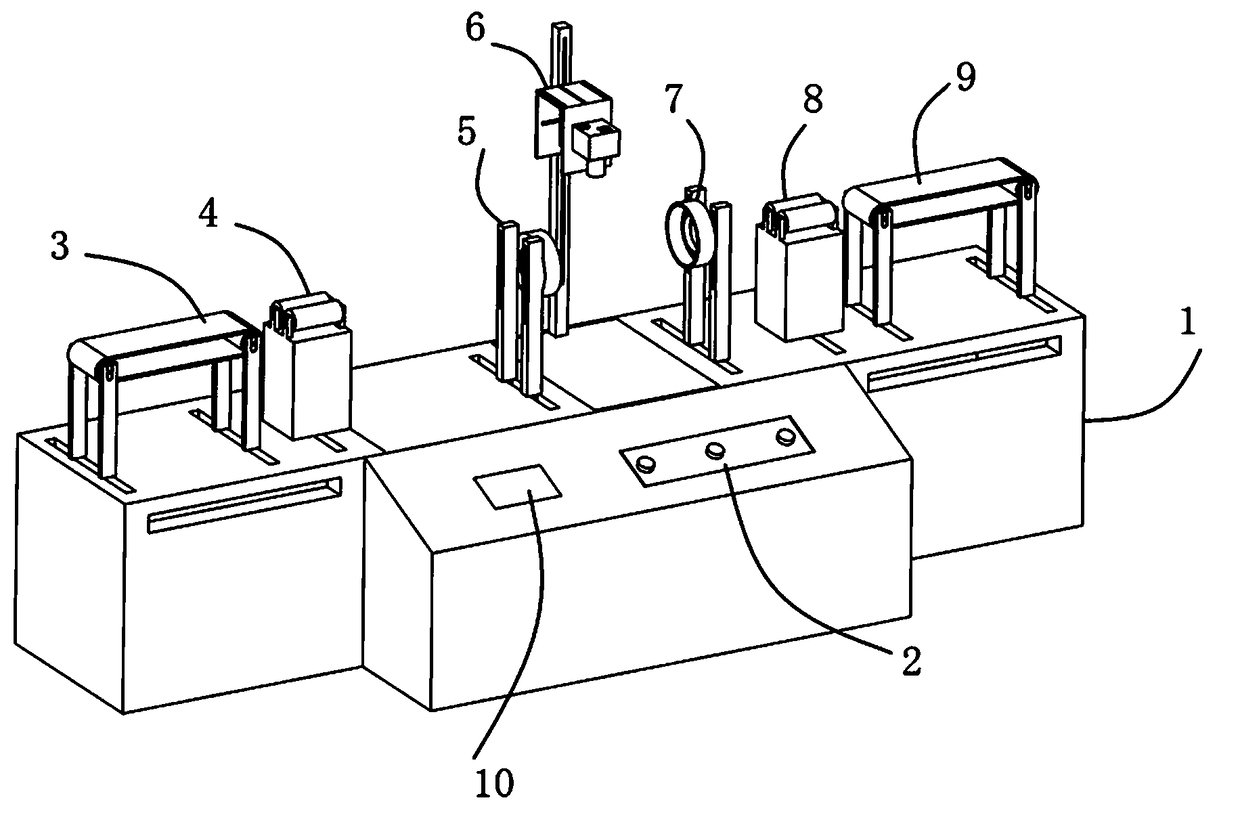

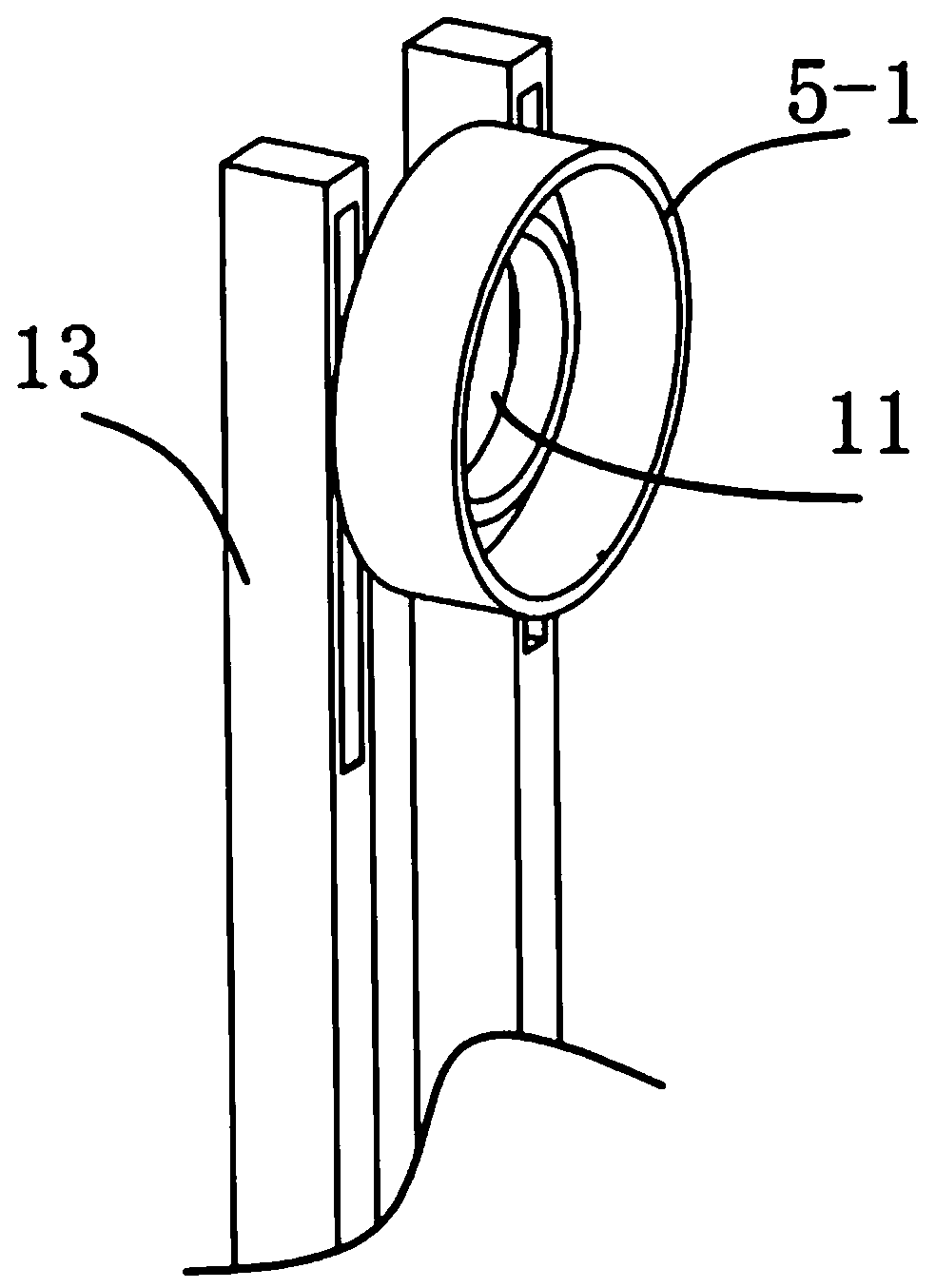

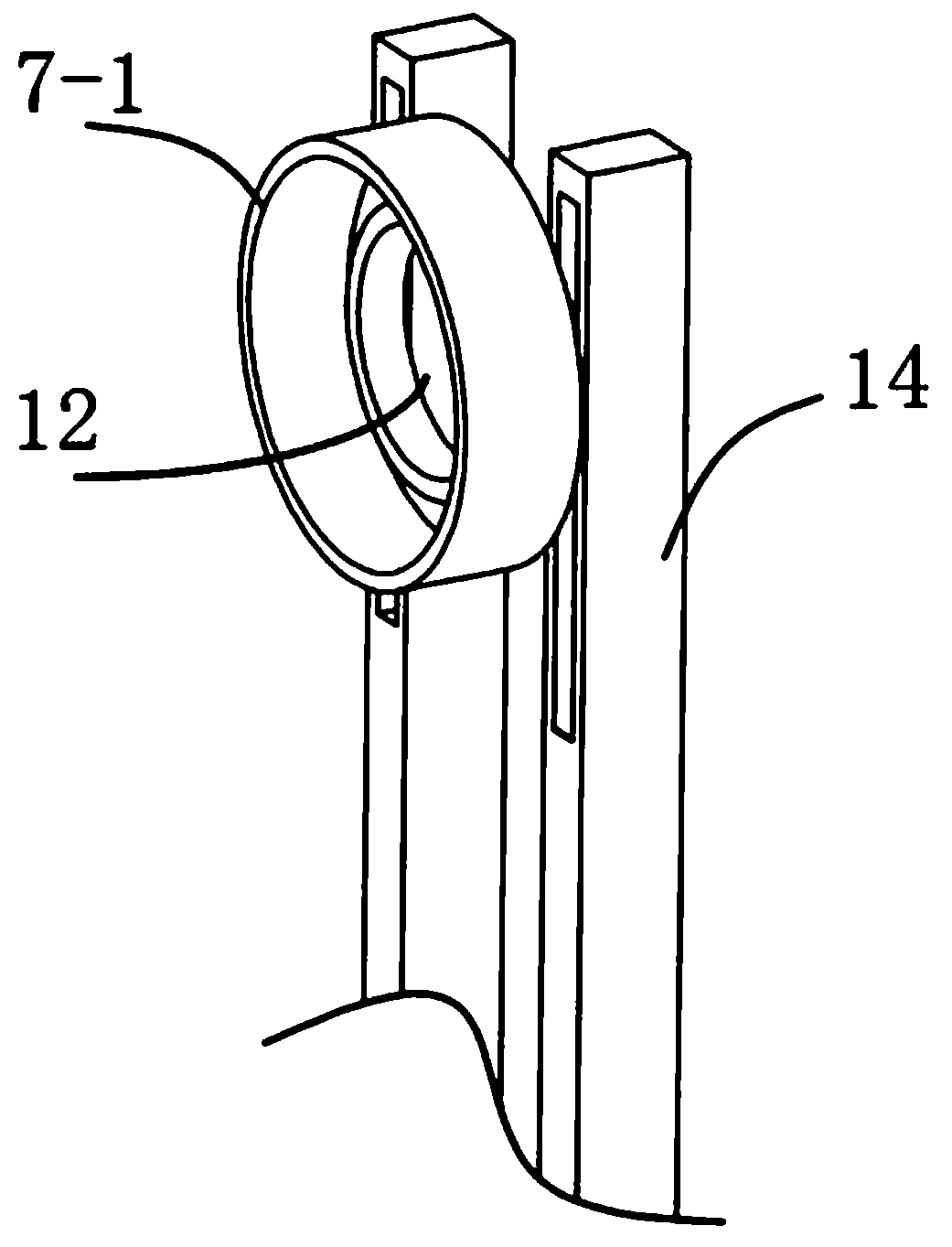

[0055] refer to figure 1 , a seamless steel pipe quality inspection device, the cabinet 1 is provided with a console 2 and a sequentially connected first conveyor belt 3 electrically connected to the console 2, a first rotary table 4, a first light source unit 5, and an industrial camera 6. The second light source unit 7, the second rotary table 8 and the second conveyor belt 9, wherein the first light source unit 5 is provided with a first ring light source 5-1 and the second ring light source 7 on the second light source unit 7 -1 is irradiated with light in opposite directions, and the illumination ranges of the first ring light source 5-1 and the second ring light source 7-1 partially overlap, the first ring light source 5-1 is provided with a first perforation 11, and the second ring light source 7-1 A second perforation 12 is opened on the top, and the industrial camera 6 takes pictures of the seamless steel pipe to be inspected passing between the first perforation 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com