Coarse-fraction tailing paste filling method and system

A paste filling and coarse-grained technology, which is applied in the direction of filling, earth square drilling, mining equipment, etc., can solve the problems that it is difficult to meet the needs of filling, the tailings slurry cannot be released, and the overflow water of the sand bin is turbid. Achieve the effect of avoiding raking accidents, reducing the risk of raking, and clear overflow water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

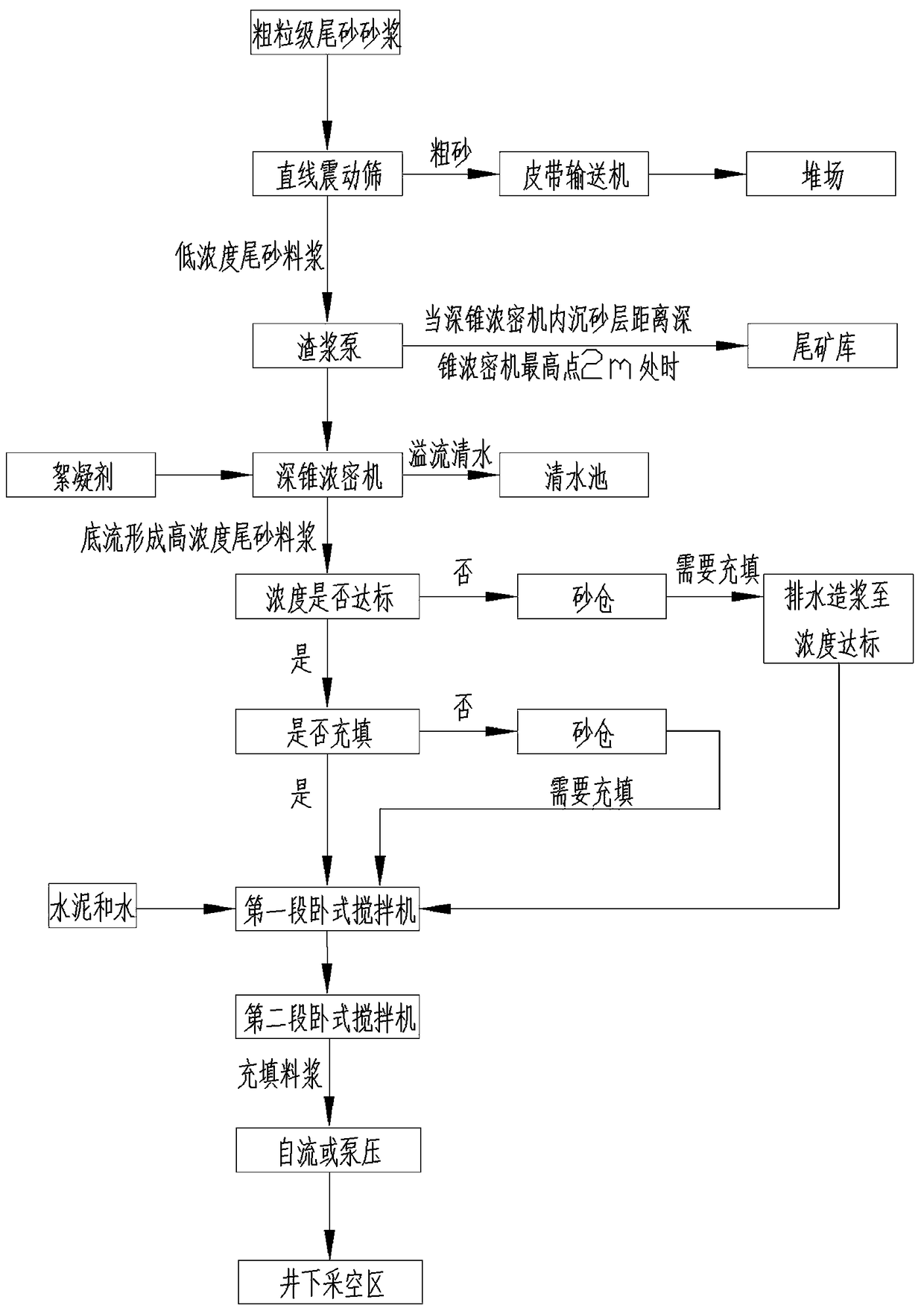

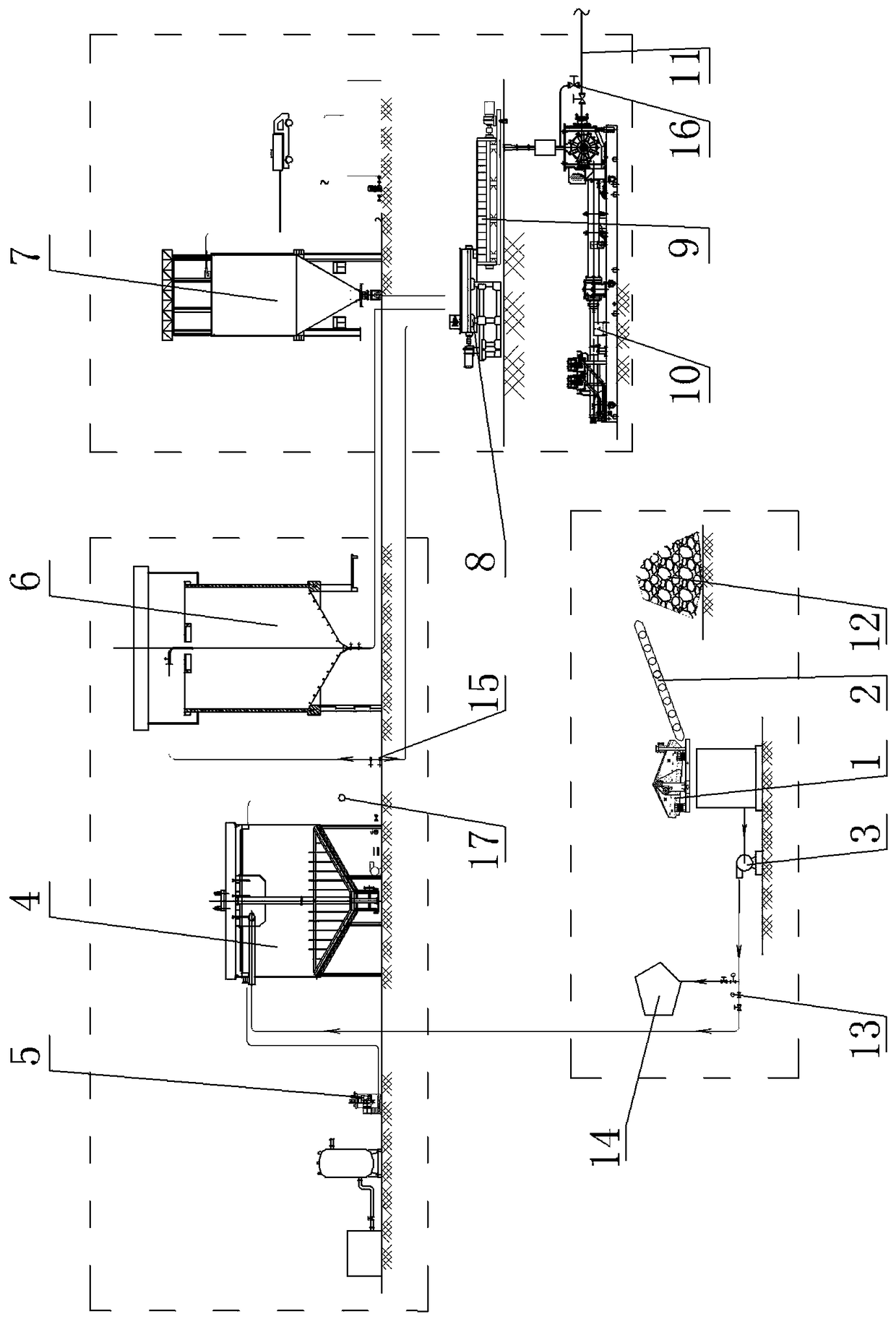

[0035] from figure 1 It can be seen that this coarse-grained tailings paste filling method of the present invention comprises the following steps:

[0036] (1) Transport the coarse-grained tailings mortar from the concentrator to the linear vibrating screen, screen to obtain coarse sand and low-concentration tailings slurry, and send the coarse sand to the storage yard for storage through a belt conveyor;

[0037] (2) Pump the low-concentration tailings slurry obtained in step (1) to the deep cone thickener with a cone angle of 45° through the slurry pump and wear-resistant pipeline, and at the same time, according to the underflow concentration of the deep cone thickener, The flocculant is added to the deep cone thickener, and the overflow clear water of the deep cone thickener flows to the clear water tank 17 by itself, and the bottom flow forms a high-concentration tailings slurry; when the sand settling layer in the deep cone thickener is 2m away from the highest point of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com