Collection device for cleaning residual slurry of concrete pouring pump pipe of high-rise floor slab

A collection device and high-rise technology, which is applied in the field of collection devices for cleaning up the residual slurry of high-rise floor concrete pouring pump pipes, can solve the problems of affecting civilized construction, staining walls, and inconvenient cleaning methods, so as to improve the image of civilized construction and collect device Simple structure, avoid the effect of arbitrary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The collecting device for cleaning the residual slurry of the concrete pouring pump pipe of the high-rise floor of the present invention comprises a triangular support, a corrugated pipe and a residual slurry collector.

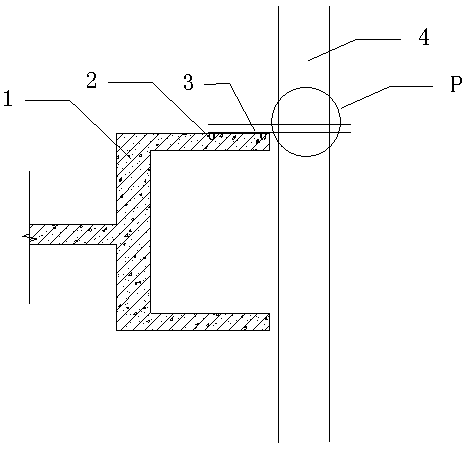

[0034] see now figure 1 and figure 2 , figure 1 It is a schematic diagram of setting the tripod bracket of the embodiment of the present invention, figure 2 for figure 1 The enlarged picture of the P part in the figure shows the schematic diagram of the structure of the bellows clamped by the triangular bracket. As shown in the figure, the triangular bracket is connected and fixed by three steel pipes with pipe clamps, wherein: the first steel pipe 3 is horizontally arranged outside the high-rise outer wall 1, and one end of the first steel pipe is fixed by the embedded bolt 2 in the outer wall ;

[0035] The diameter of the bellows is 300mm plastic bellows, the bellows are clamped in the middle of the tripod, and the bellows are perpendicular t...

Embodiment 2

[0038] A method for erecting a collection device for cleaning the residual slurry of pump pipes in high-rise floor slabs, characterized in that it includes the following steps:

[0039] a. A number of pre-embedded bolts 1 are arranged on every third floor outside the high-rise exterior wall 1;

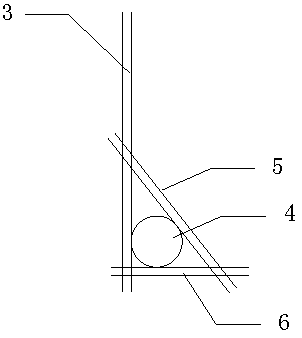

[0040] B, make some right-angled triangular supports, wherein: the first steel pipe 3 is vertically connected and fixed with the third steel pipe 6, and the second steel pipe 5 is used as a diagonal bar of the right-angled triangular support;

[0041] c. Connect and fix one end of the first steel pipe 3 with the embedded bolt 1, so that the plane fixed by the three steel pipes of the right-angled triangular bracket is horizontal;

[0042] d. Provide a corrugated pipe 4, the diameter of the corrugated pipe is 300mm plastic corrugated pipe, so that the corrugated pipe is clipped into the right angle formed by the two right-angled side steel pipes of the right-angled triangle bracket, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com