Efficient filter element for water purifier

A high-efficiency filtration and purifier technology, used in filtration treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of low filtration efficiency of water purification filter elements, achieve high space utilization, high filtration accuracy, and ensure safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

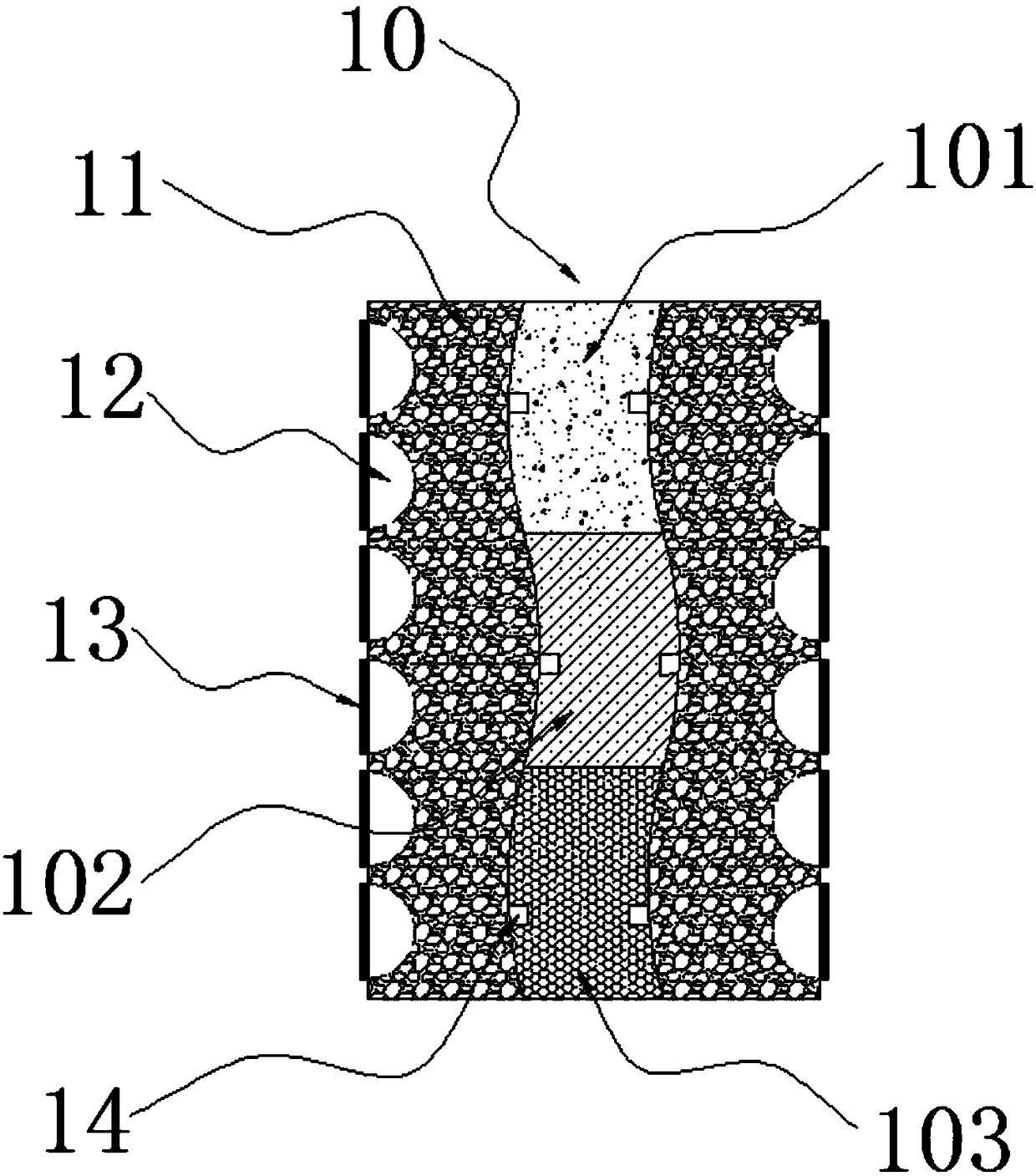

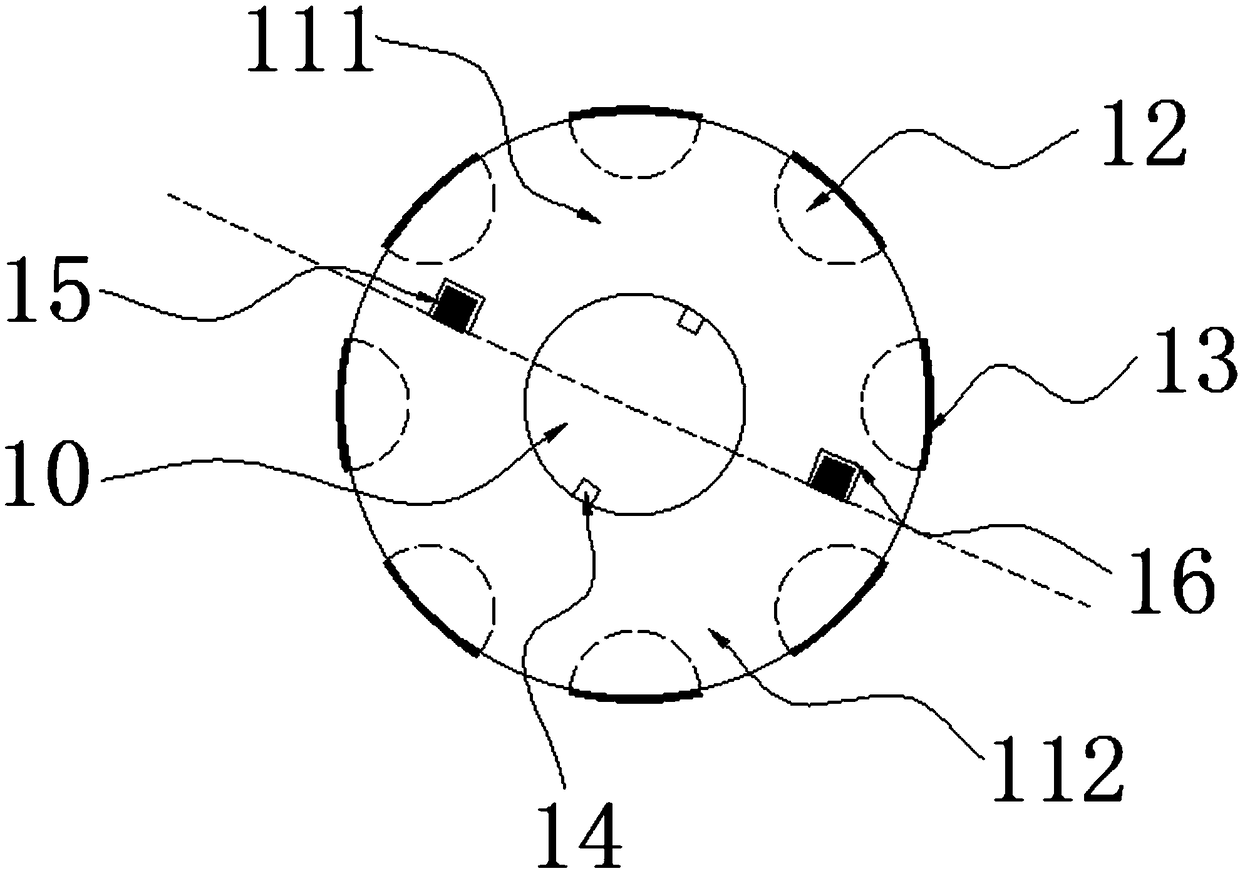

[0037] refer to Figure 1-2 As shown, a high-efficiency filter element for a water purifier includes an outer filter channel 11 and an inner filter channel 10, and the outer filter channel 11 includes a first outer filter channel 111 and a second outer filter channel 112, said An inner filter channel 10 is provided in the middle of the outer filter channel 11 to form a cylindrical structure. The inner filter channel 10 is equidistantly divided into three filter sections, and fixed blocks 14 are arranged symmetrically inside the three filter sections. The circular cross-section and sides of the filter passage 11 are uniformly provided with several filter grooves 12,

[0038] The three filter sections are sequentially filled with KDF filter material 101, PP melt-blown filter element 102 and ultra-filter element 103 from top to bottom.

[0039] The KDF filter material 101 is KDF55.

[0040] The filter diameter of the ultra filter element 103 is 0.001 μm.

[0041] The inner fil...

Embodiment 2

[0049] refer to Figure 1-2 As shown, a high-efficiency filter element for a water purifier includes an outer filter channel 11 and an inner filter channel 10, and the outer filter channel 11 includes a first outer filter channel 111 and a second outer filter channel 112, said An inner filter channel 10 is provided in the middle of the outer filter channel 11 to form a cylindrical structure. The inner filter channel 10 is equidistantly divided into three filter sections, and fixed blocks 14 are arranged symmetrically inside the three filter sections. The circular cross-section and sides of the filter passage 11 are uniformly provided with several filter grooves 12,

[0050] The three filter sections are sequentially filled with KDF filter material 101, PP melt-blown filter core 102 and ultra-filter core 103 from top to bottom.

[0051] The KDF filter material 101 adopts KDF85.

[0052] The filtration diameter of the ultra-filter element 103 is 0.005 μm.

[0053] The inner f...

Embodiment 3

[0061] refer to Figure 1-2 As shown, a high-efficiency filter element for a water purifier includes an outer filter channel 11 and an inner filter channel 10, and the outer filter channel 11 includes a first outer filter channel 111 and a second outer filter channel 112, said An inner filter channel 10 is provided in the middle of the outer filter channel 11 to form a cylindrical structure. The inner filter channel 10 is equidistantly divided into three filter sections, and fixed blocks 14 are arranged symmetrically inside the three filter sections. The circular cross-section and sides of the filter passage 11 are uniformly provided with several filter grooves 12,

[0062] The three filter sections are sequentially filled with KDF filter material 101, PP melt-blown filter element 102 and ultra-filter element 103 from top to bottom.

[0063] The KDF filter material 101 is KDF55.

[0064] The filter diameter of the ultra filter element 103 is 0.009 μm.

[0065] The inner fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com