Propulsion device of full-circle rotating guide cover type water vehicle

A technology of water vehicles and propulsion devices, which is applied in the direction of ship propulsion, propulsion components, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

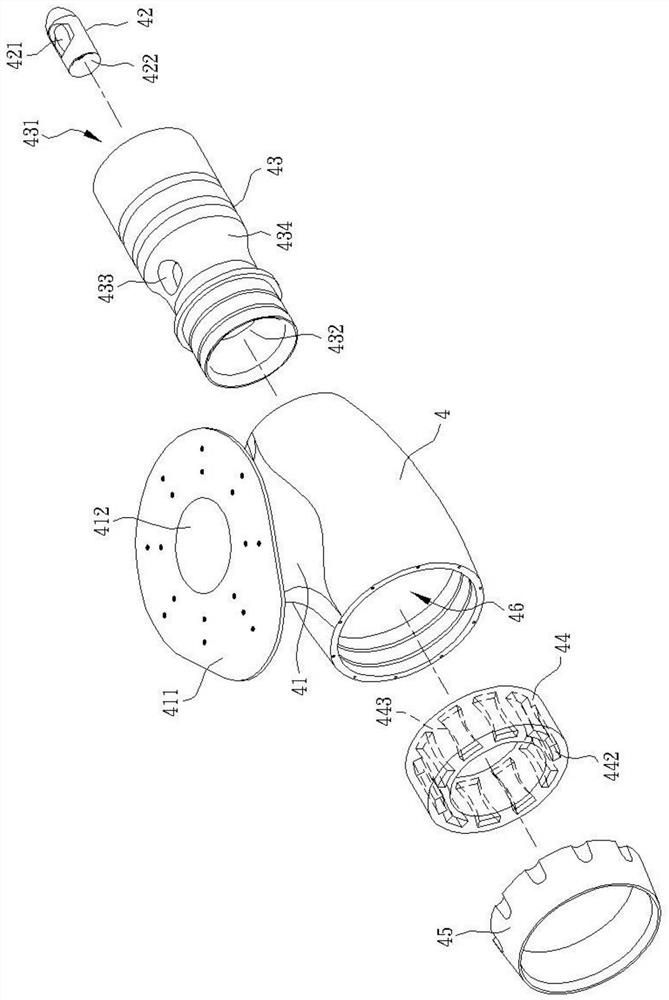

[0083] Please refer to shown in Figures 1 to 5, it can be known that the main structure of the present invention includes: connecting pipe 2, support and steering assembly 3, and main flow pipe 4; wherein the connecting pipe 2 is formed by an inner pipe with the same center 21 and an outer tube 22 are compounded.

[0084] In actual application, the connecting pipe 2 can pass through a default through hole 51 on a hull structure 5, and the hull structure 5 is tightly fitted and fixed on a hull 60 at the tail end of a predetermined hull 6, One end of the connecting pipe 2 is arranged inside the hull 60, and the other end of the connecting pipe 2 extends to the outside of the hull 60, and an outer joint 23 is horizontally arranged in the middle section of the connecting pipe 2, and the outer joint 23 23 is close to the outer side of the hull structure 5 .

[0085] In addition, a connecting pipe supporting waterproof bearing ring 52 and a gap plate 24 are respectively provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com