Automatic glass digital printing system and using method thereof

A digital printing and glass technology, applied to printing devices, printing, typewriters, etc., can solve the problems that the pattern cannot be changed in time, the cleaning fluid is corrosive, and cannot be carried out, so as to prevent pollution, reduce labor costs, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

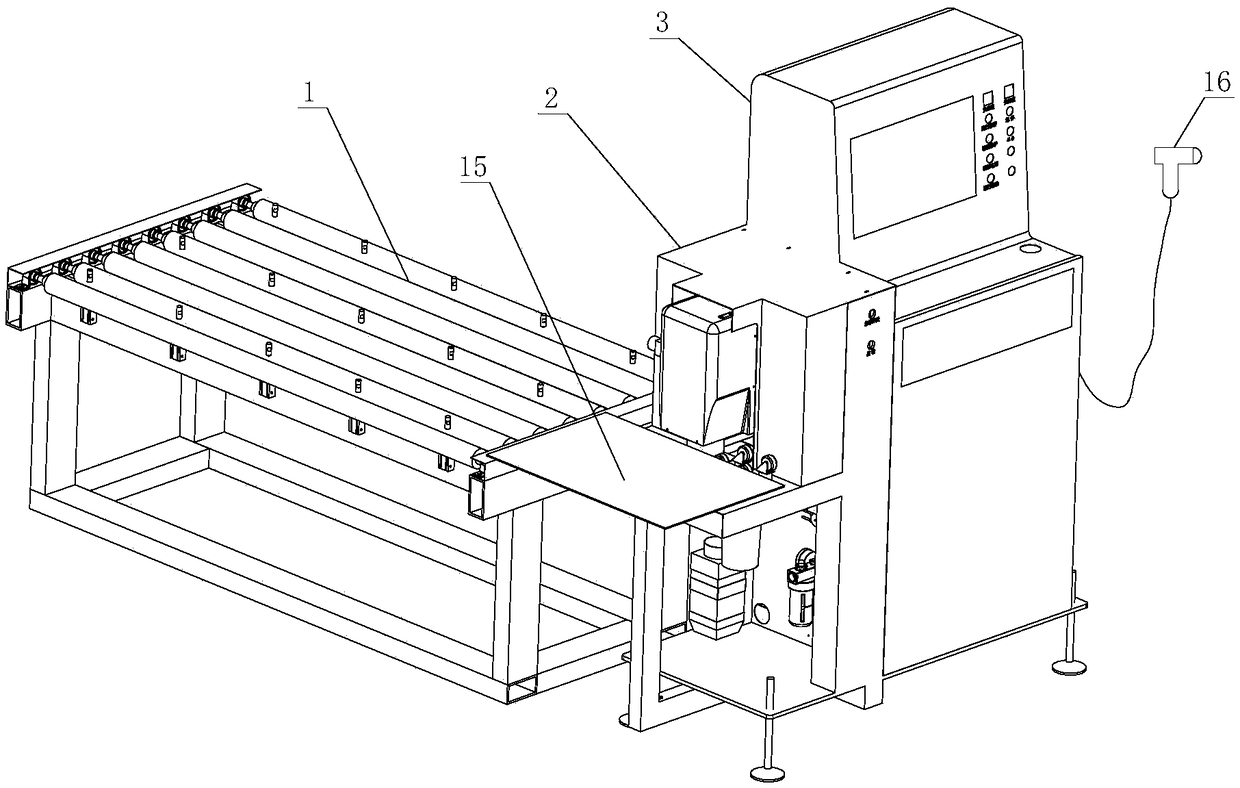

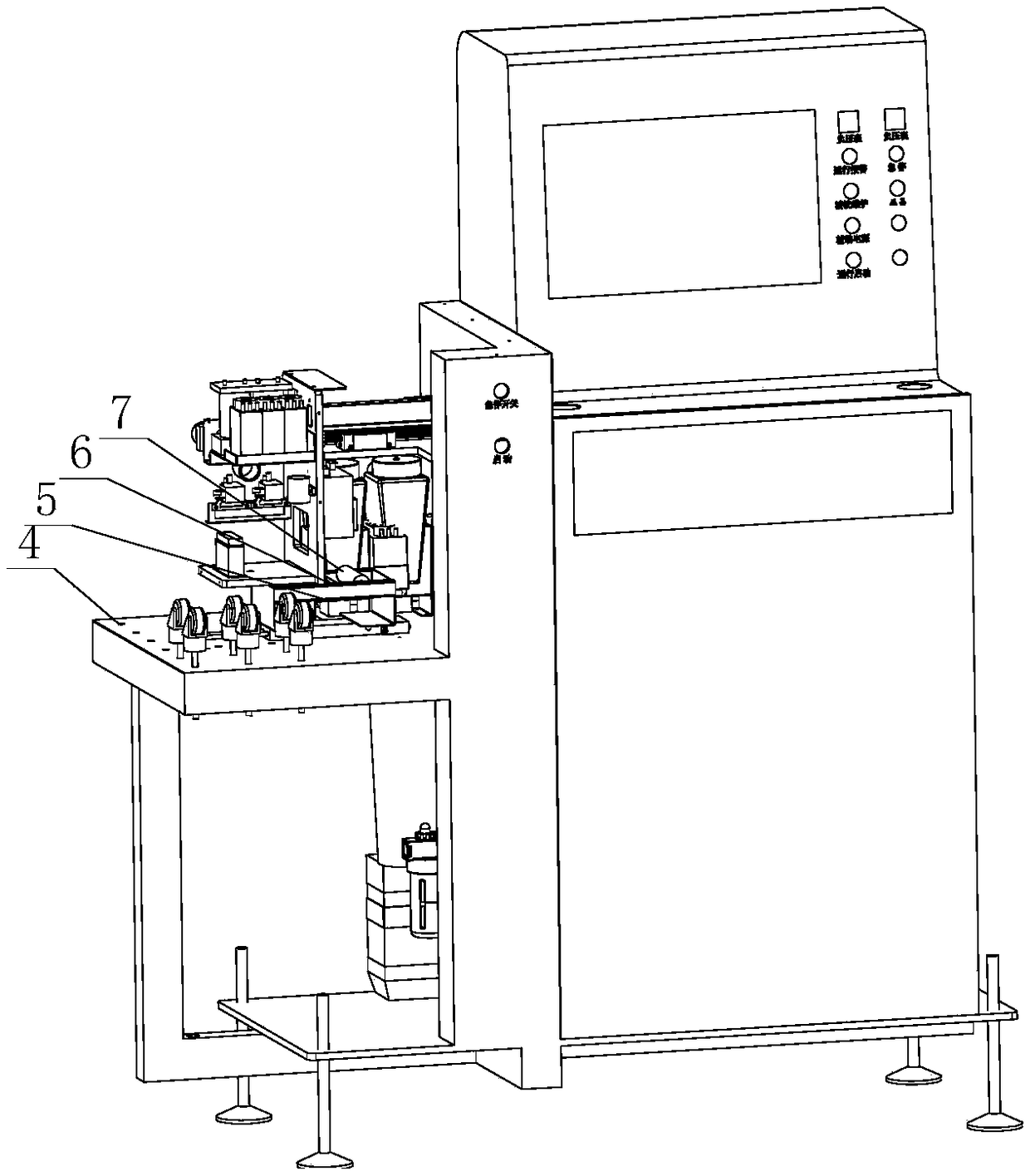

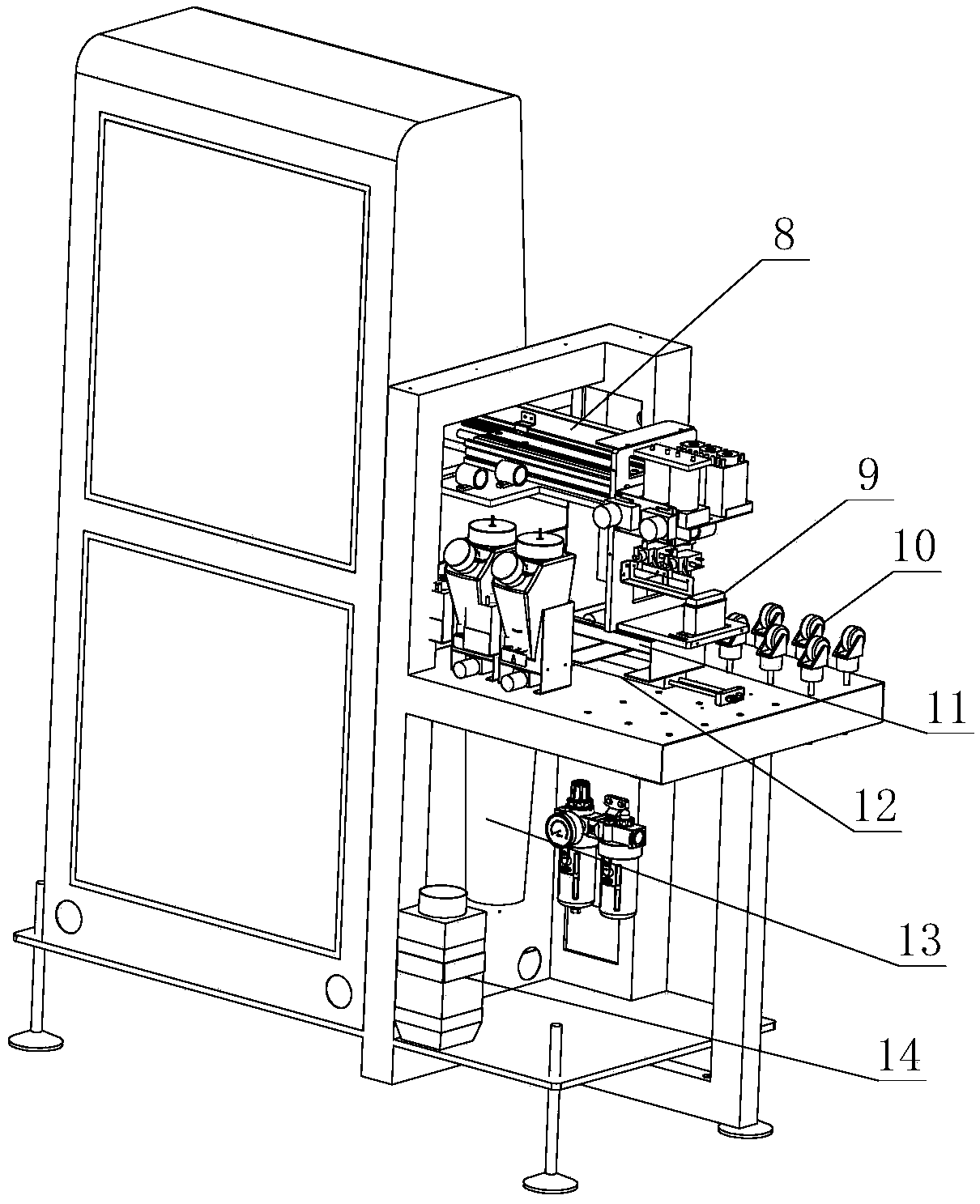

[0029] Embodiment 1 of the digital printing system: as Figure 1-Figure 4 As shown, an automated glass digital printing system is located upstream of the glass 15 high-temperature heating furnace, including a device body 2 and a manipulator, and the manipulator is located on one side of the device body 2; the device body 2 is provided with a glass printing platform 4, and the device body 2 There is also a control system 3, a first telescopic device 8, and a digital printing device 9; the first telescopic device 8 and the digital printing device 9 are both electrically connected to the control system 3, and the first telescopic device 8 is installed in the On the device body 2 , the digital printing device 9 is connected to the telescopic end of the first telescopic device 8 .

[0030] The device body 2 also includes a second telescopic device 12 and a cleaning device 11. The second telescopic device 12 is installed on the device body 2, the cleaning device 11 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com