Fixing structure of forming core of layered injection molding and layered injection mold

A technology for fixing structures and positioning structures, which can be applied to household appliances, other household appliances, optical components, etc., and can solve problems such as unstable fixation of injection molding cores, and achieve the effects of stable position, lower requirements, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

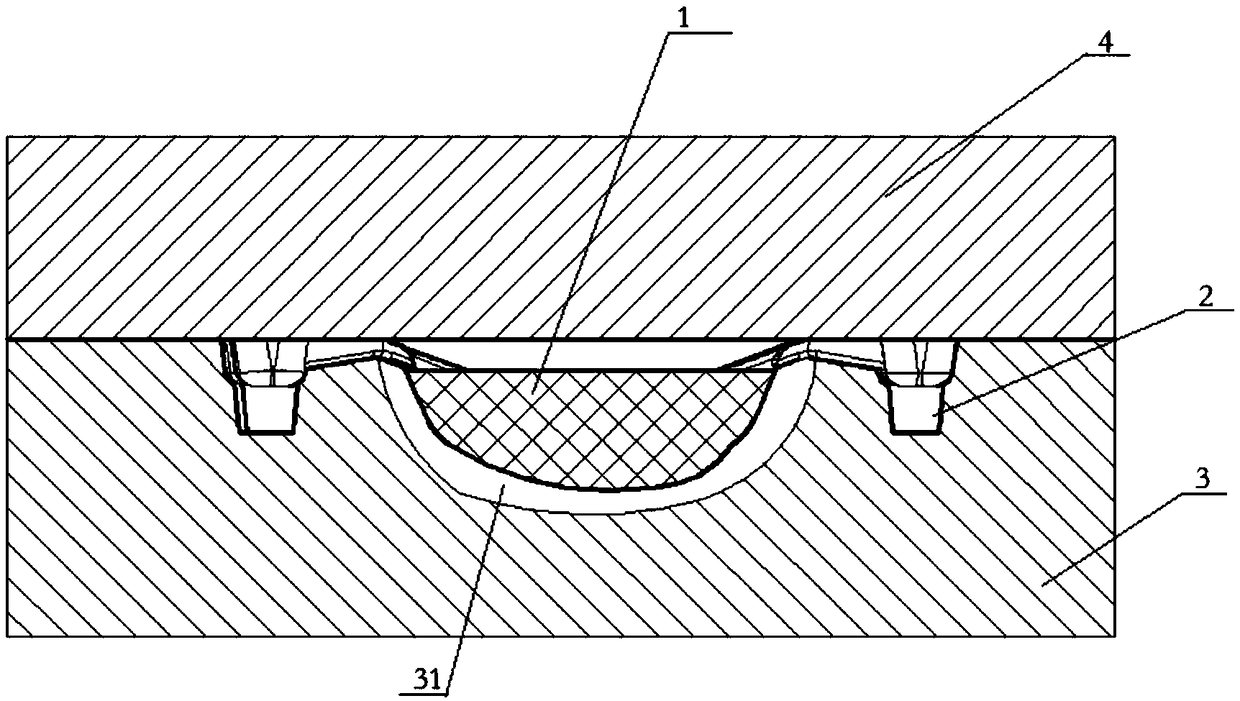

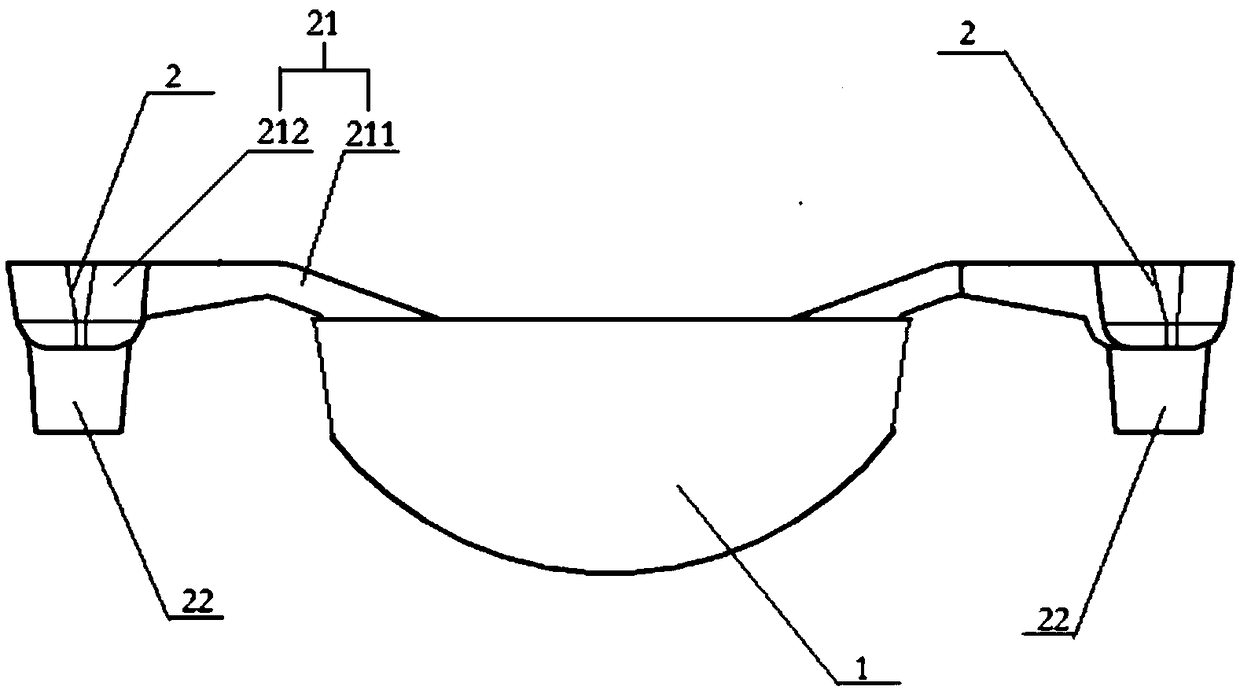

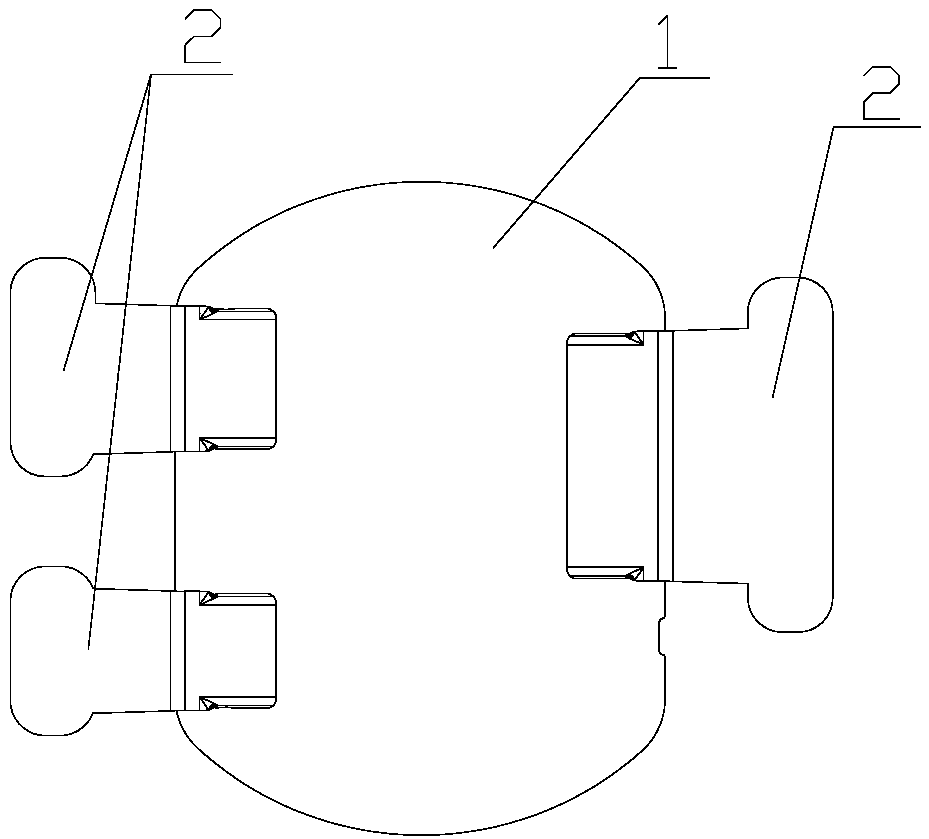

[0027] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] like Figure 1-5 As shown, the present embodiment provides a fixed structure of the forming core of layered injection molding, the fixed structure and the forming core 1 are integrally formed, the fixed structure extends outward from the edge of the forming core 1, and the fixed structure is used for the layered injection molding. The forming core 1 is suspended and fixed in the mold cavity 31 of the next injection molding, which is convenient for layered injection molding of the forming core 1 .

[0029] This embodiment is applicable to the injection molding preparation of lenses, which are transparent wall thickness products in the automotive lamp industry. Since the lens has a relatively thick wall thickness, it can be produced by multi-layer injection molding. The shape of the forming core 1 is reasonably set according to the shape of the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com