A portable three-hole drilling machine

A kind of hole drilling machine, portable technology, applied in the field of portable three-hole drilling machine, can solve the problems of cumbersome, complicated, time-consuming and labor-intensive, inconvenient to carry and move, large volume of drilling machine, etc., achieve good stability, prevent air leakage and looseness, and clean the surface of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

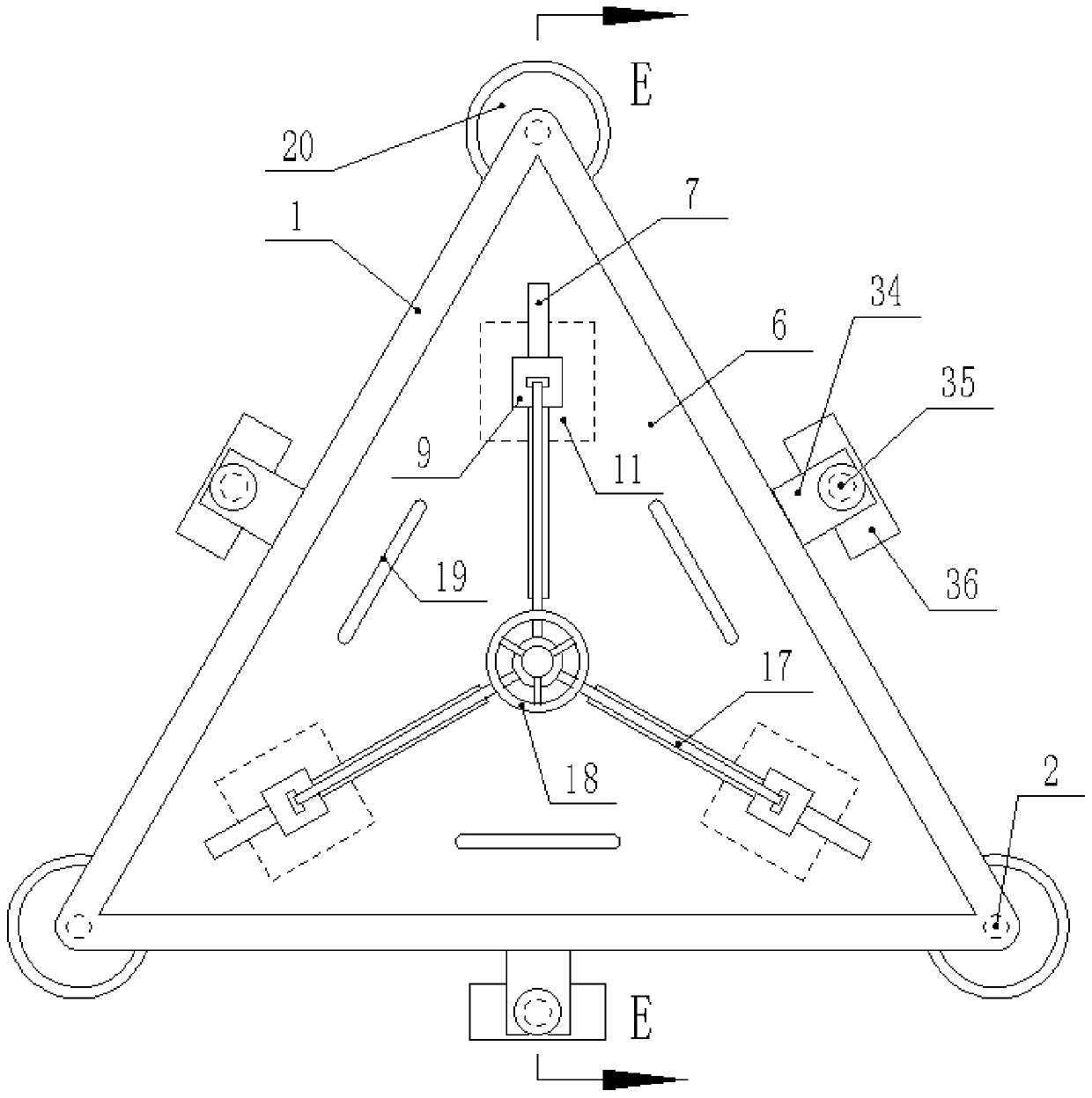

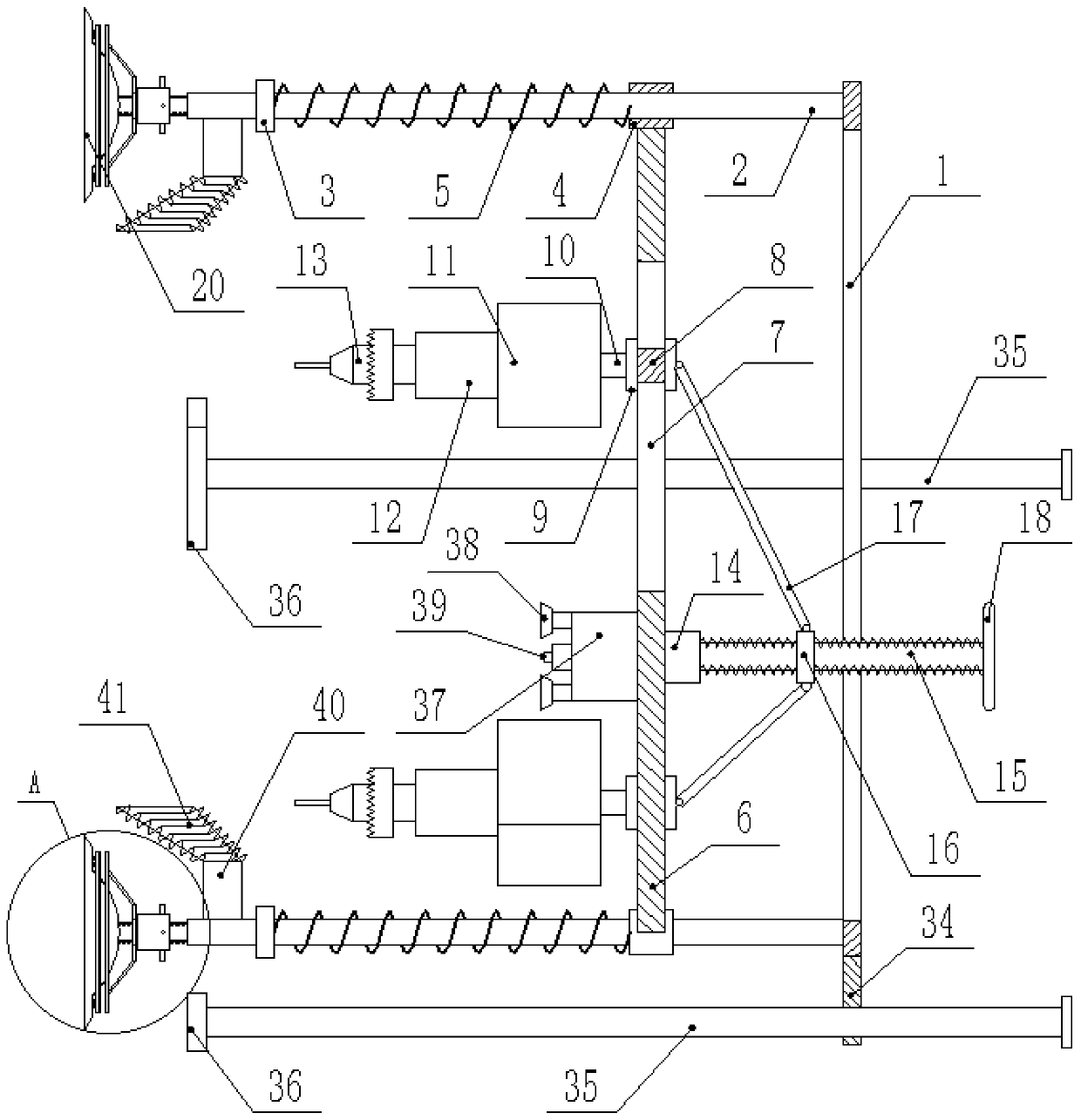

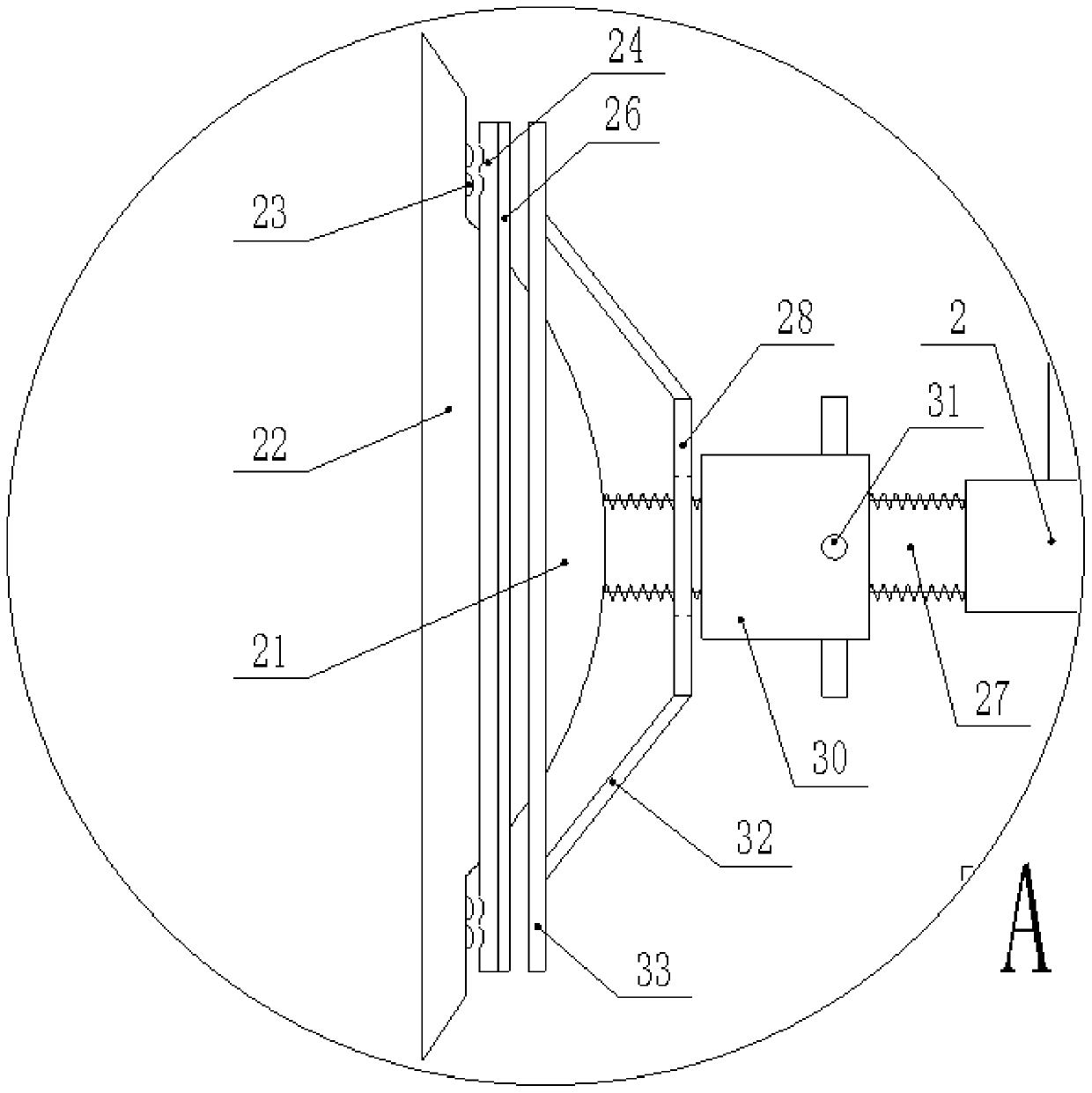

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a portable three-hole drilling machine includes a fixed frame 1, the shape of the fixed frame 1 is a triangle, each corner of the fixed frame 1 is vertically fixed with one end of the fixed rod 2, and the other end of the fixed rod 2 is fixed There is a suction cup 20, the other end of the fixed rod 2 is covered with a stop ring 3 fixedly connected with it, the middle of the fixed rod 2 is covered with a sleeve 4 slidingly connected with it, and a The spring 5 sleeved on the outer wall of the fixed rod 2 is fixed with a fixed plate 6 corresponding to the fixed frame 1 between the sleeves 4. The shape of the fixed plate 6 is a triangle, and the fixed plate 6 is arranged in an array at its center position. There are three chute 7, the chute 7 is provided with a slider 8 slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com