An automatic meat grinder

A meat grinding and automatic technology, which is applied in mixers with rotating stirring devices, transportation and packaging, grain processing, etc., can solve the problems of low efficiency of grinding meat, and achieve the effect of improving work efficiency, ensuring taste, and uniform size

Active Publication Date: 2019-09-17

唐山中红食品有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide an automatic meat grinding device to solve the problem of low meat grinding efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

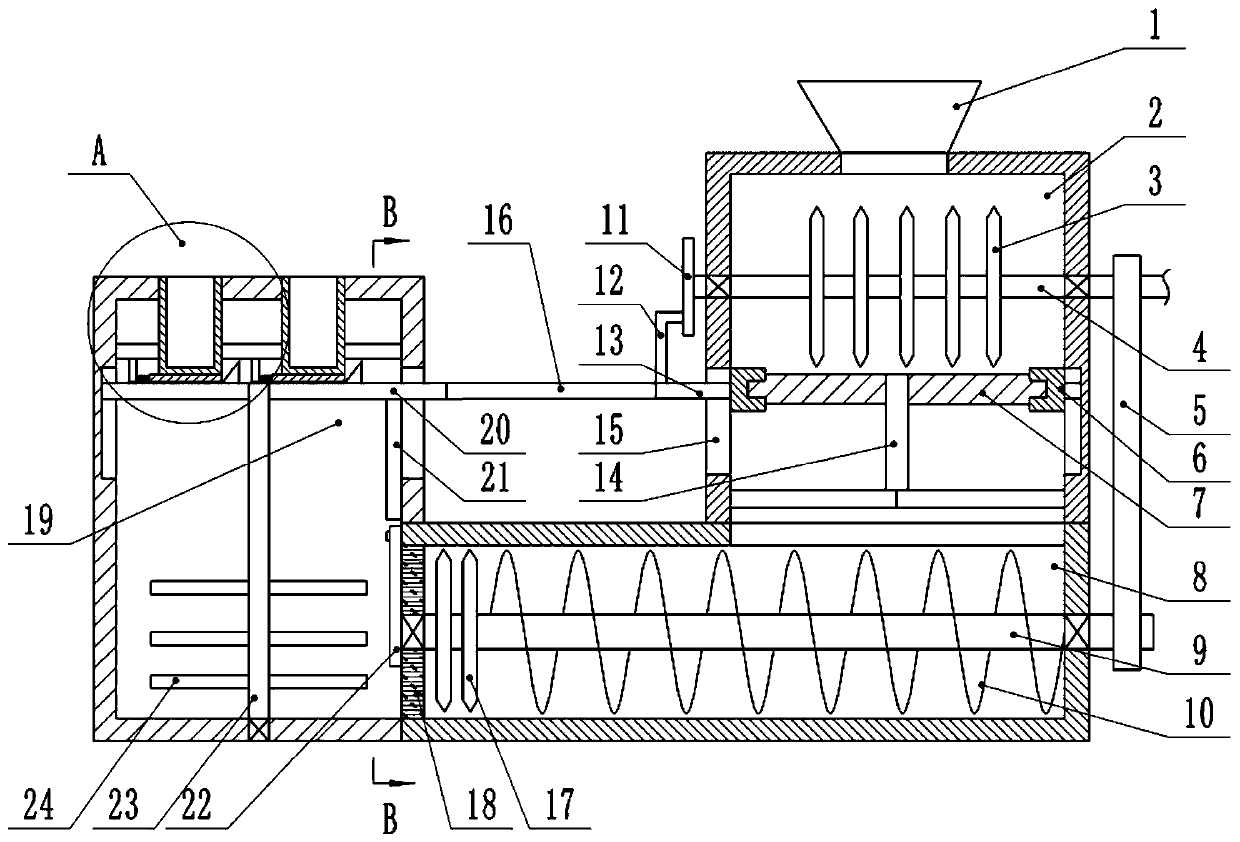

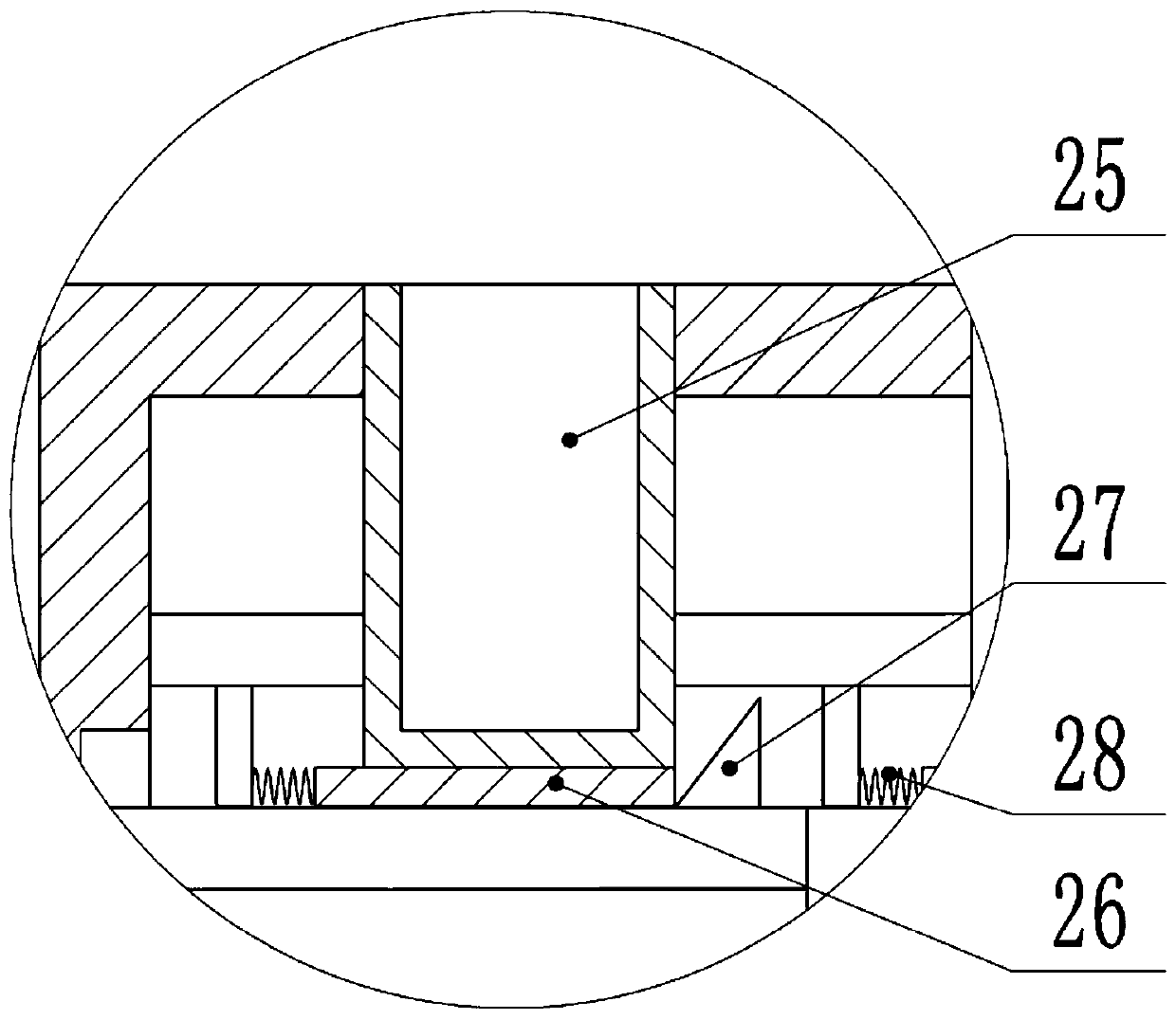

The invention belongs to the technical field of edible meat processing equipment, and specifically discloses an automatic meat grinding device, which includes a meat grinding cylinder and a meat cutting cylinder. The inner rotation is connected with a sieve plate, the end of the meat cutting shaft is provided with a lifting mechanism, the inside of the meat cutting cylinder is connected with a screw rod, and the sieve plate is provided with a screw hole. The meat grinding cylinder communicates with the lower part of the meat cutting cylinder, and the meat grinding cylinder is provided with a meat grinding mechanism for conveying and grinding meat. There is a mixing tube on the left side of the meat grinding tube, and several seasoning tubes are arranged on the upper part of the mixing tube, and a material door is slidably connected to the bottom wall of the seasoning tube. There is a push plate slidingly in the material barrel, and a stirring shaft is connected to the rotation in the mixing barrel. The wedge-shaped block that can push the material door is arranged on the pushing plate. It is a screw rod, screw holes are set on the push plate, and the push plate is fixedly connected with the annular plate. This scheme realizes automatic meat cutting, mincing and mixing, and has high work efficiency.

Description

technical field [0001] The invention belongs to the technical field of edible meat processing equipment, and in particular relates to an automatic meat grinding device. Background technique [0002] Fragrant pig belongs to Artiodactyla order, Porcudaridae, and the genus Suis. It is famous all over the country for its small body, precocious maturity, and delicious meat. Fragrant pigs are also known as "mini pigs". Among them, Congjiang fragrant pigs and Jianbai fragrant pigs from the Qiandongnan area of Guizhou, which were awarded the "Hometown of Chinese Fragrant Pigs" by the national agricultural department, and Bama fragrant pigs from Guangxi, which is close to the Qiandongnan area of Guizhou. The most famous ones are the Huanjiang Fragrant Pig and Tibetan Fragrant Pig, all of which are dwarf pig breeds. Fragrant pig has four characteristics of "one small, two fragrant, three pure, and four clean". It is a high-protein and low-energy food with comprehensive nutriti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B02C18/30B02C18/34B26D1/12B07B1/28B01F7/16

CPCB02C18/301B02C18/305B02C18/34B07B1/28B26D1/12B01F27/80

Inventor 吴廷勇王晓霞

Owner 唐山中红食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com