Electricity-saving water-saving non-mechanical stirring incremental upgrading microvortex coagulating sedimentation clarification pond

A coagulation sedimentation and clarification tank technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, sedimentation separation, settling tank, etc., can solve the problems of large volume, large floor area, and high civil construction costs, and achieve the optimization of the overall structure and reduction The effect of a small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

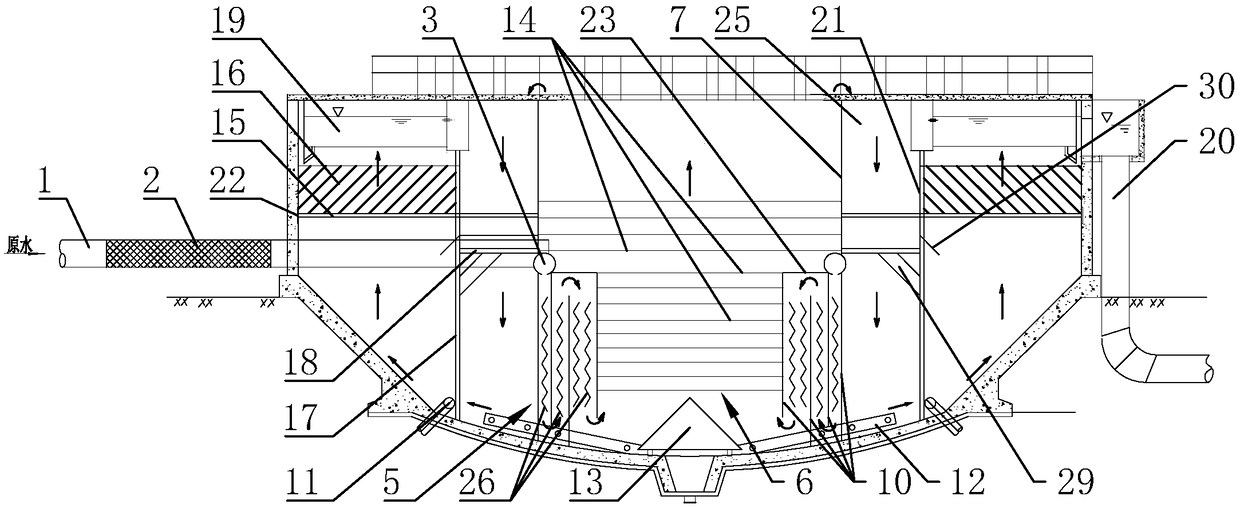

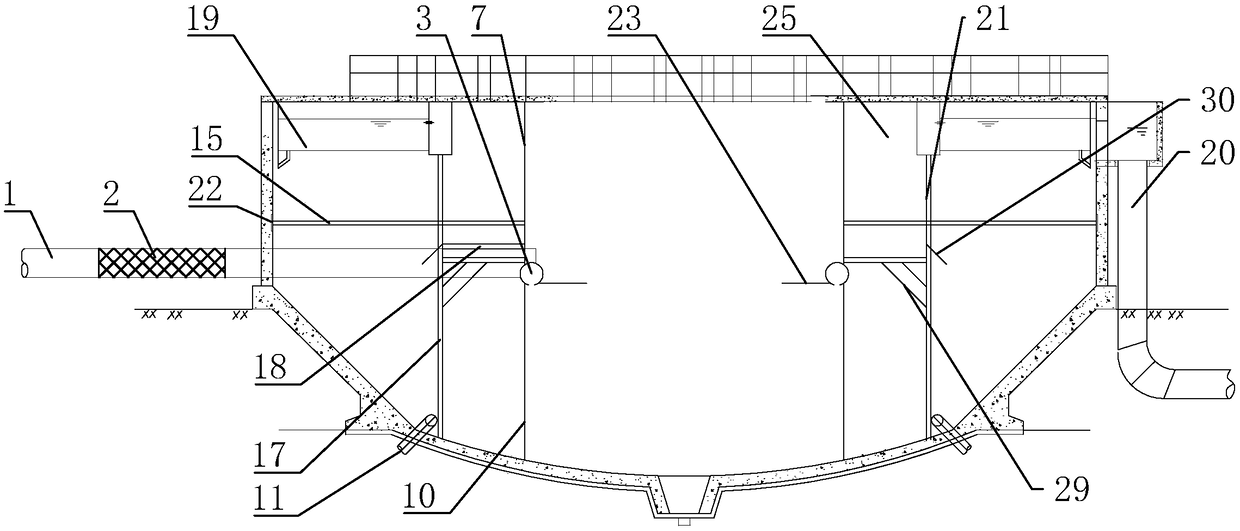

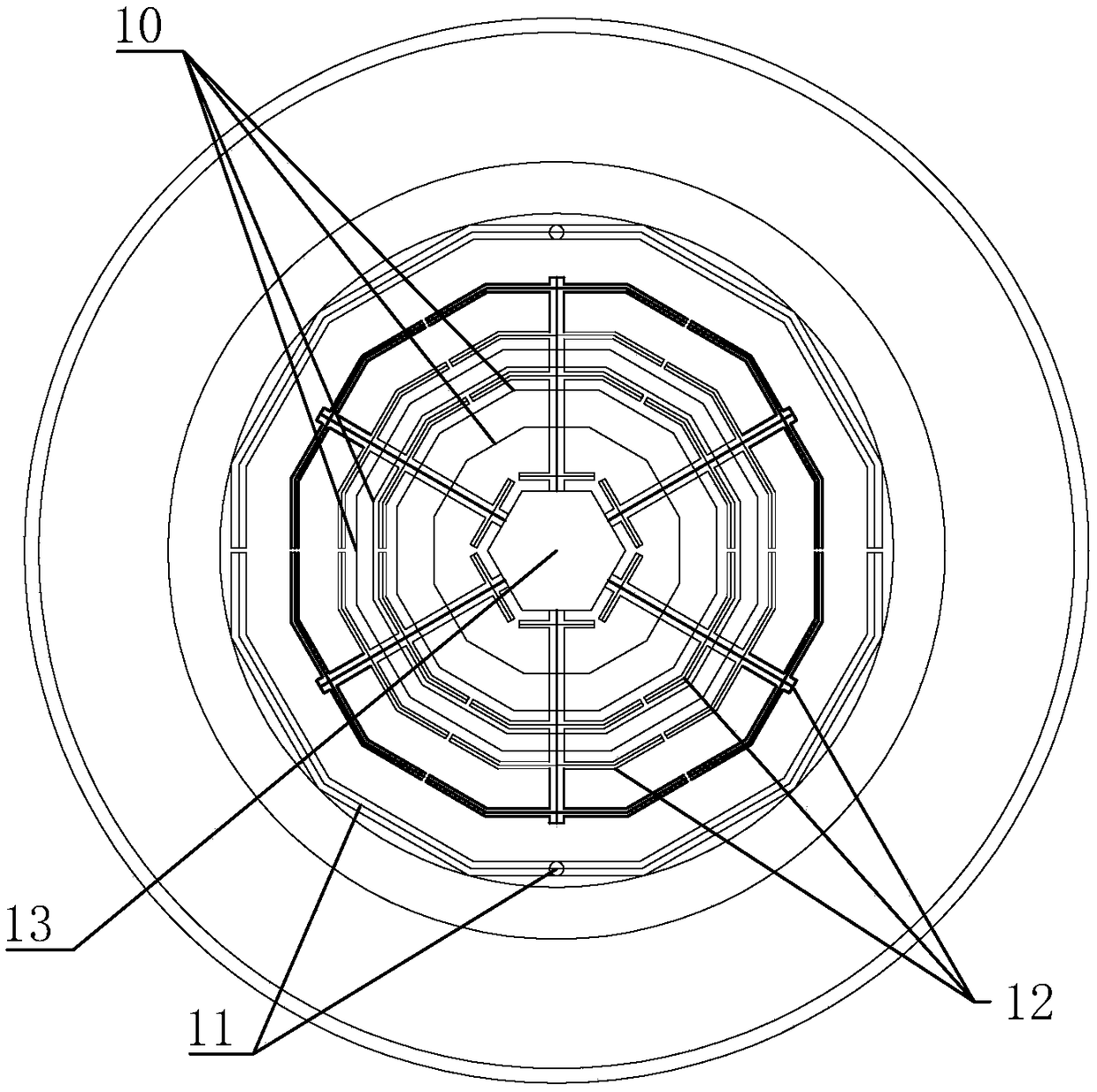

[0042] The present invention will be further described in detail below in conjunction with the drawings.

[0043] Such as figure 1 with Figure 8 As shown, a micro-vortex coagulation sedimentation clarification tank with power and water saving without mechanical stirring, increment and quality upgrading, includes an inlet pipe 1, an outlet pipe 20, and a flocculation device and a clarification device arranged in the clarification tank. The flocculation device is set In the center of the sedimentation tank, the clarification device is set in the annulus between the flocculation device and the side wall of the sedimentation tank; the inlet pipe 1 is connected to the vortex mixing equipment 2, and the entrance of the vortex mixing equipment 2 is provided with a flocculant dosing port 27 and the outlet is opened Coagulant dosing port 28; among them,

[0044] The flocculation device includes a multi-stage folded plate flocculation channel 5 and a multi-stage grid flocculation channel 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com