Three-dimensional roll-like structure with self-regulating structure function, preparation method and application thereof

A technology for adjusting structure and three-dimensional tubular shape, which is applied in chemical instruments and methods, pharmaceutical equipment, and other medical equipment, etc. It can solve problems such as organ transplant failure, patient death, and outstanding antibacterial problems, and achieve the effect of simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

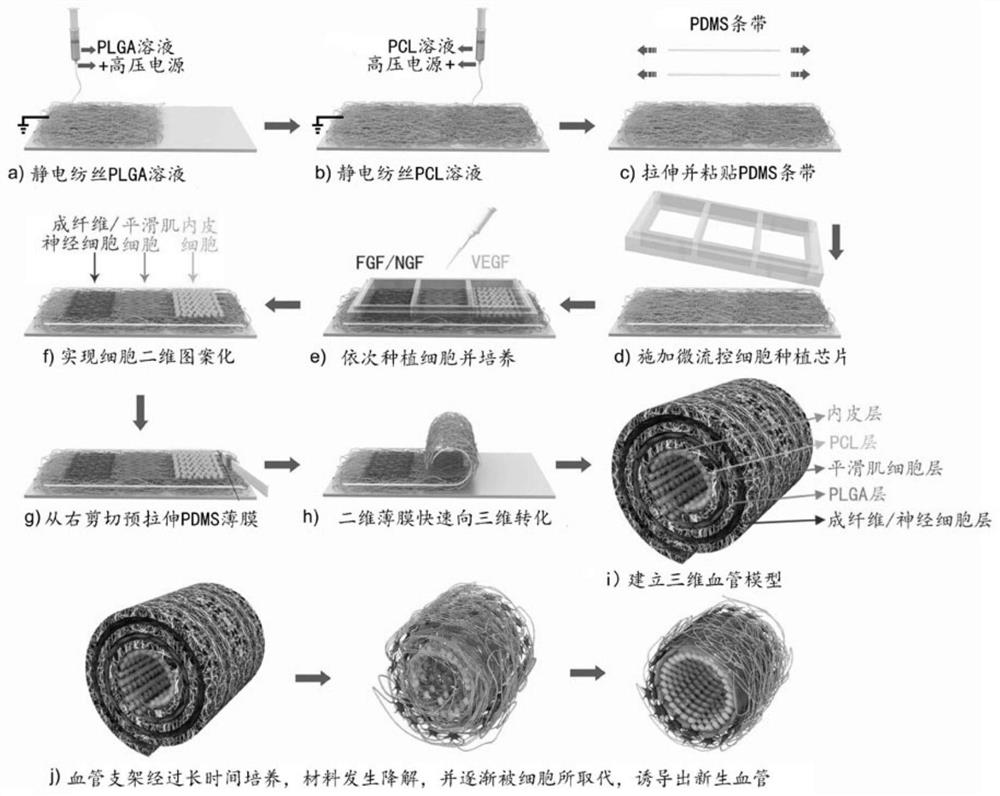

[0080] This example is used to illustrate the preparation method of the electrospinning film. For the specific scheme and results, please refer to image 3 a-c and Figure 4 a-e.

[0081] First, two degradable polymer materials with different degradation rates, PLGA and PCL, were selected as the base materials of the scaffold. As a solvent, stir and mix well for electrospinning film preparation.

[0082] Using electrospinning technology, applying a high-voltage power supply of 15kV, and selecting hexafluoroisopropanol as a solvent, two polymer solutions were prepared. The concentration of PCL solution was 10wt%, the concentration of PLGA solution was 20wt%, and the receiving distance was 15cm. The final PLGA solution The diameter is about 0.7 μm, the diameter of PCL is about 0.6 μm, and the porosity is 70%. Finally, an electrospinning film with a thickness of about 80 μm is prepared. The film has two components, one is the PCL layer with a slower degradation rate, and the ot...

Embodiment 2

[0084] This example is used to illustrate the surface modification of electrospinning films and the two-dimensional patterning of cells. For specific schemes and results, see image 3 d-f, Figure 4 f and Figure 5 a.

[0085]First, design and process a PMMA template with a three-channel (or multi-channel) structure, pour it with a PDMS solution (matrix: curing agent mass ratio of 10:1), and place it in an oven at 80 °C for heating and curing for 1 h. The cured PDMS is removed from the template. Remove the top and bottom, trim the edges, use a puncher to punch three channels (or multi-channels) (with a diameter of 8 mm), prepare microfluidic seeding chips in turn, and use the prepared three-channel cell seeding microfluidic chips for For the regionalized planting of cells, after attaching the PDMS chip to the surface of the electrospinning film, Fibronectin (50 μg / ml) was first added to modify the spinning surface to facilitate cell adhesion; then three cells were seeded. I...

Embodiment 3

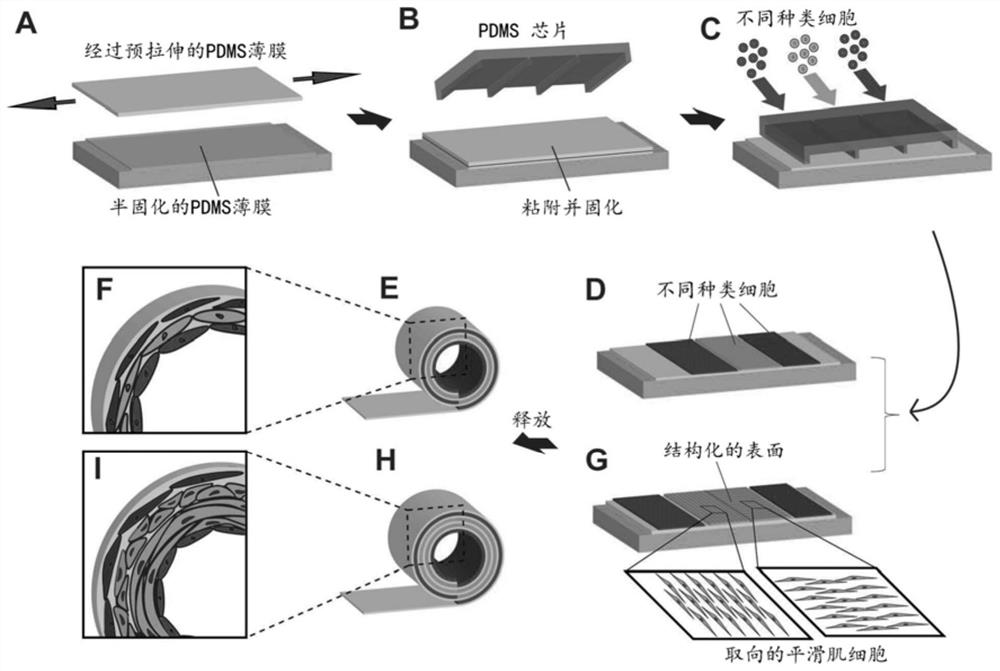

[0087] This example is used to illustrate the three-dimensional transformation of the two-dimensional patterned film. For the specific scheme and results, please refer to image 3 i-h, Figure 4 g-i and Figure 5 b-c.

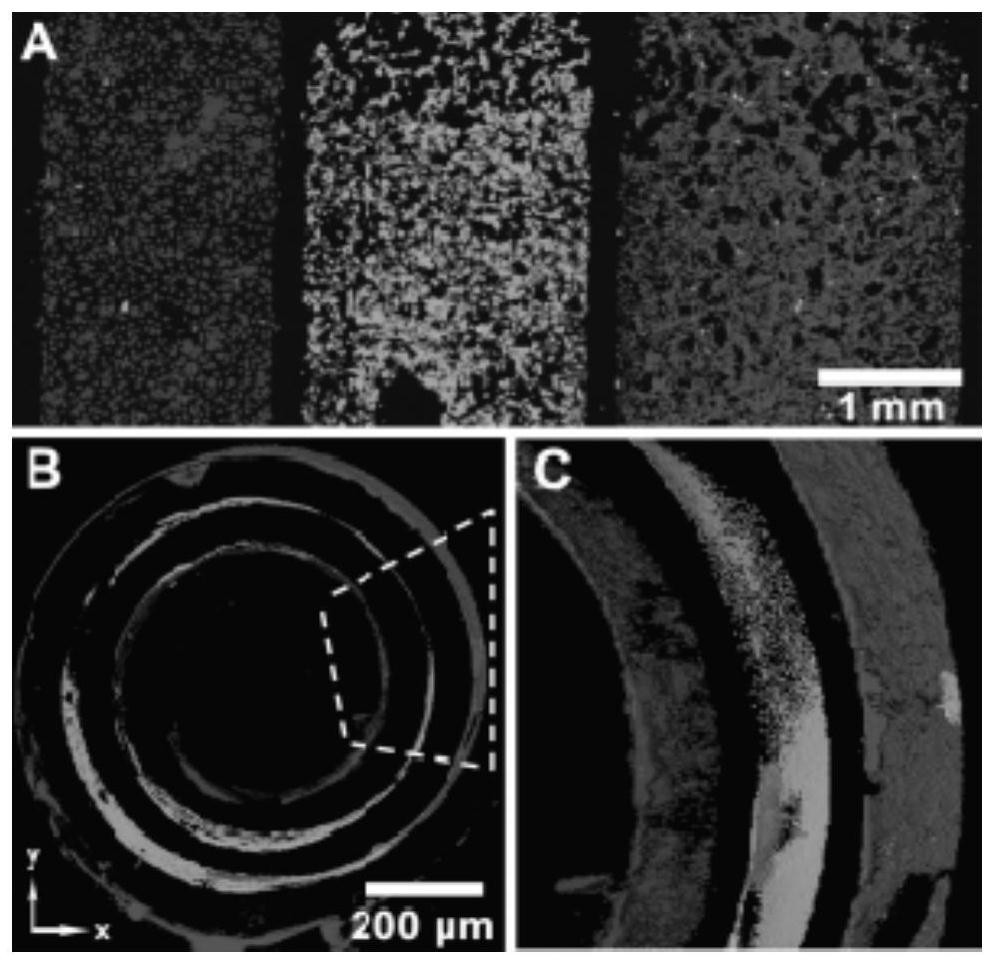

[0088] Pre-engineered tension-induced self-curling films ( image 3 c), it has a double-layer structure, the bottom layer is an electrospun drug-loaded film, and the upper layer is a pre-stretched PDMS strip with a strain of 70% and a thickness of about 80 μm. The spun films are glued together to form a complete layer. Since PDMS has a certain internal stress after pre-stretching, when the cells are attached, the film and PDMS strip are cut from the right side with a scalpel, and the film will be automatically curled to form a multi-layer roll structure with a specific inner diameter. . The structure has 6 layers, from inside to outside: endothelial layer, PCL layer, smooth muscle cell layer, PLGA layer, fibroblast / neural cell layer, PLGA layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com