Anti-wrinkle repair composition and application thereof to cosmetics

A technology of composition and cosmetics, applied in the direction of cosmetics, cosmetic preparations, dressing preparations, etc., can solve the problems of loss of activity, difficulty in penetration, and difficulty in penetration of active ingredients, and achieve the effect of restoring internal balance and accelerating regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

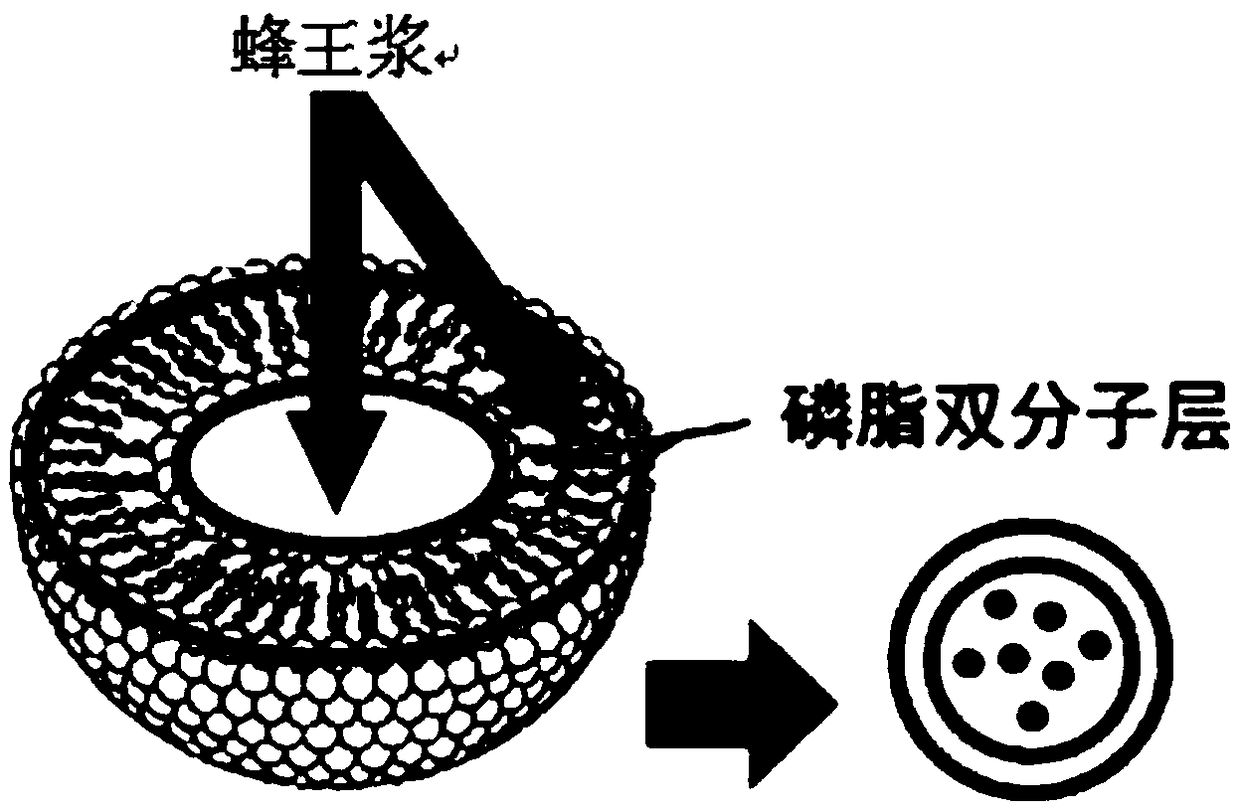

[0041] Embodiment 1 (preparation embodiment of liposome product)

[0042] 10g of royal jelly (dry weight) and 50g of lecithin are used in a mass ratio of 1:5, using a high-pressure homogenization process, which specifically includes the steps:

[0043] 1. Add 50 grams of lecithin into 600 grams of 76.7% ethanol aqueous solution by volume, and stir at room temperature until it dissolves evenly;

[0044] 2. Add the mixture of step 1 into the high-pressure homogenizer, add 10 g of royal jelly (dry weight) into the high-pressure homogenizer, and homogenize at room temperature and high speed for 10 minutes;

[0045] 3. After vacuum stirring and evaporating until there is no ethanol, the royal jelly is wrapped with lecithin to make a liposome product, and the active content of royal jelly is about 5%.

[0046] The liposome has a double-layer structure, and the active ingredient of royal jelly is distributed in the center of the liposome or the part of the double-layer phospholipid ...

Embodiment 2

[0047] Embodiment 2 (preparation embodiment of liposome product)

[0048] 6g of royal jelly (dry weight) and 30g of lecithin are used in a mass ratio of 1:5, using a high-pressure homogenization process, which specifically includes the steps:

[0049] 1. Add 30 grams of lecithin into 600 grams of 72.7% ethanol aqueous solution by volume, and stir at room temperature until it dissolves evenly;

[0050] 2. Add the mixture of step 1 into the high-pressure homogenizer, add 6g of royal jelly (dry weight) into the high-pressure homogenizer, and homogenize at room temperature and high speed for 10 minutes;

[0051] 3. After vacuum stirring and evaporating until there is no ethanol, the royal jelly is wrapped with lecithin, and the liposome product is made. The active content of royal jelly is about 3%.

[0052] The liposome has a double-layer structure, and the active ingredient of royal jelly is distributed in the center of the liposome or the part of the double-layer phospholipid ...

Embodiment 3

[0053] Embodiment 3 (preparation embodiment of liposome product)

[0054] Royal jelly (dry weight) 4g, and lecithin 20g, with a mass ratio of 1:5, using a high-pressure homogenization process, specifically including the steps:

[0055] 1. Add 20 grams of lecithin into 600 grams of 70.67% ethanol aqueous solution by volume, and stir at room temperature until it dissolves evenly;

[0056] 2. Add the mixture of step 1 into the high-pressure homogenizer, add 4g of royal jelly (dry weight) into the high-pressure homogenizer, and homogenize at room temperature and high speed for 10 minutes;

[0057] 3. After vacuum stirring and evaporating until there is no ethanol, the royal jelly is wrapped with lecithin, and the liposome product is made. The active content of royal jelly is about 2%.

[0058] The liposome has a double-layer structure, and the active ingredient of royal jelly is distributed in the center of the liposome or the part of the double-layer phospholipid structure. The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com