cosmetic powder container

A cosmetic powder and container technology, applied in the field of cosmetics, achieves the effects of good sealing performance, stable structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

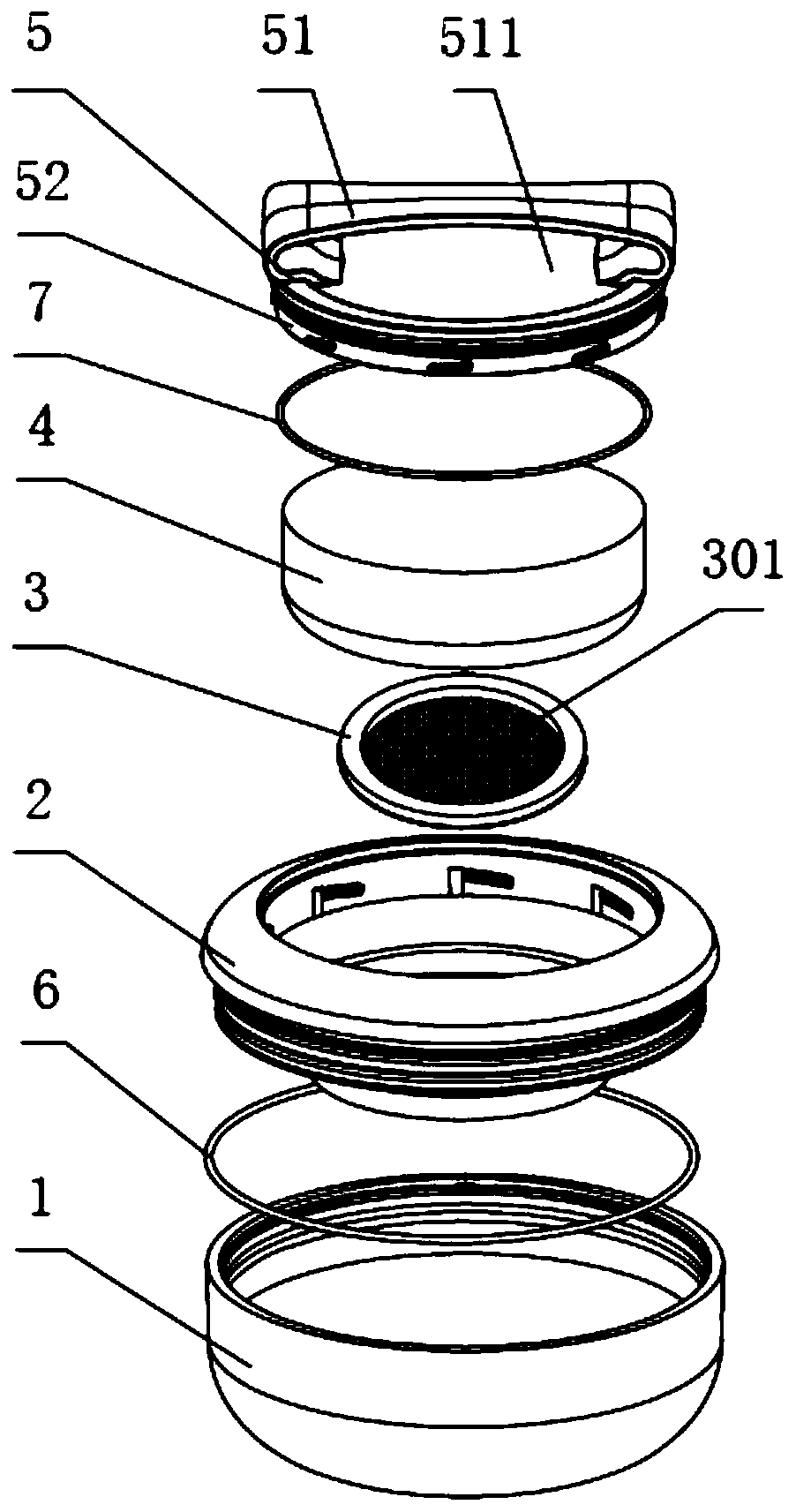

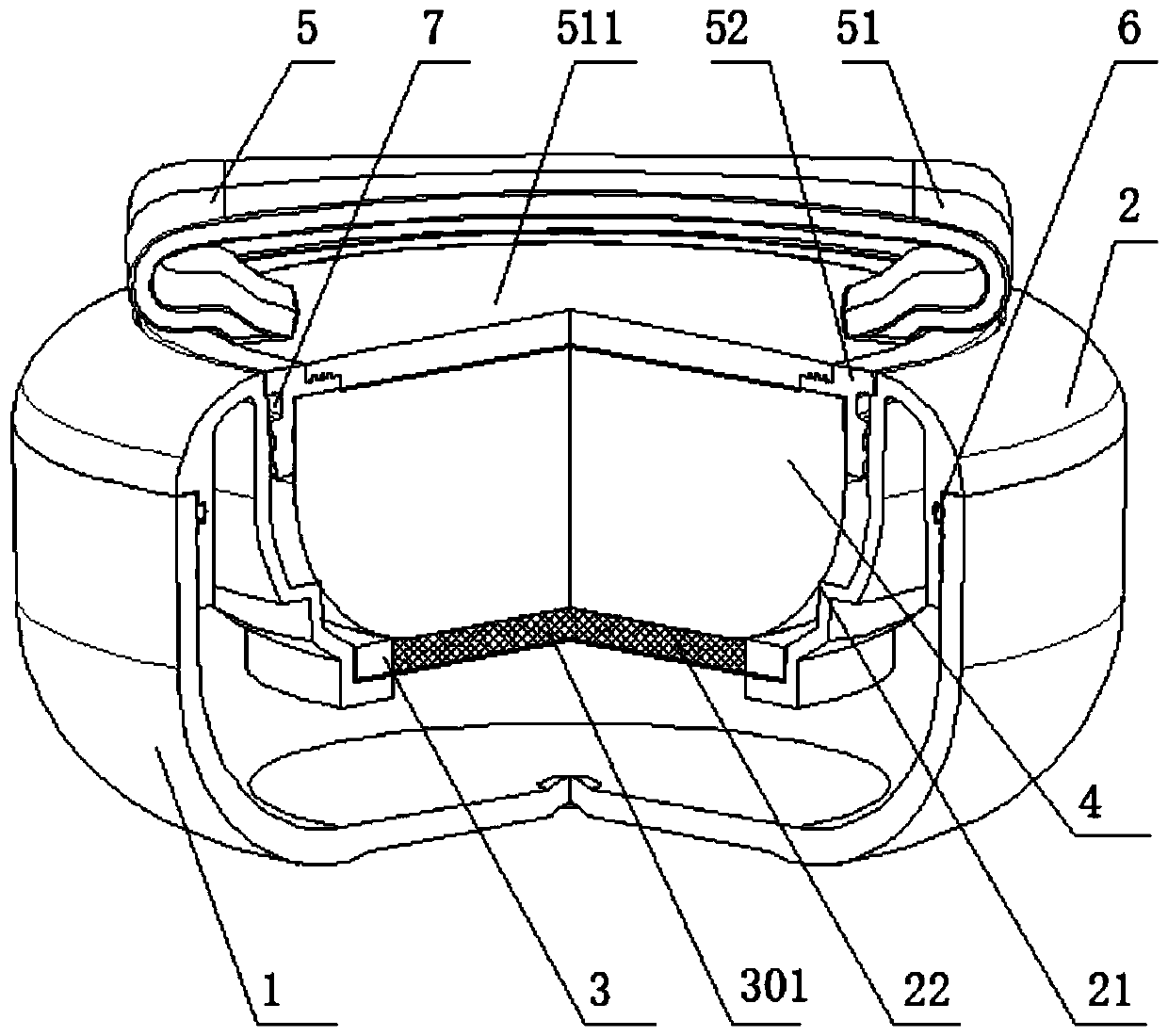

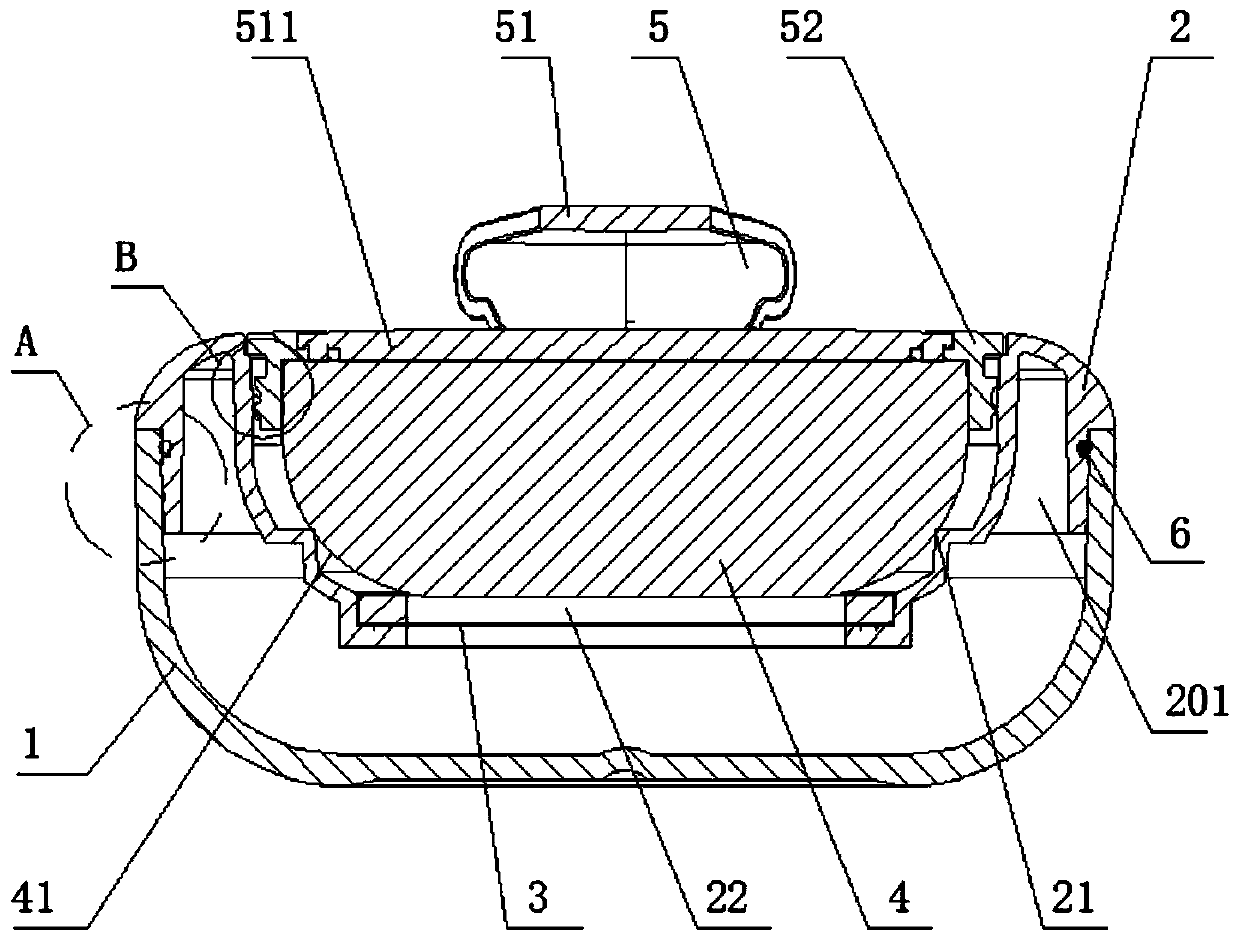

[0040] A cosmetic powder container such as figure 1 As shown, it includes a container main body 1, a shoulder cover 2, a powder discharge member 3, a makeup tool 4 and a container cover 5, and the opening of the container main body 1 faces upwards, as figure 2 , image 3 As shown, the shoulder sleeve 2 is placed on the upper end of the container body 1, for example, the shoulder sleeve 2 and the container body 1 can be screwed or snap-fitted, etc., and the connection between the container body 1 and the shoulder sleeve 2 is provided with a first sealing ring 6, such as The nitrile rubber sealing ring can be used, which has the advantages of good oil resistance, good heat resistance, and high wear resistance to ensure good sealing. The powder discharge member 3 is arranged at the bottom of the shoulder sleeve 2, and the powder discharge member 3 is provided Several powder outlet holes 301, the number of powder outlet holes 301 is determined according to specific needs, usuall...

Embodiment 2

[0049] In this embodiment, on the basis of the first embodiment, the powder discharge member 3 and the shoulder cover 2 are limited, specifically, as Figure 14 As shown, the powder discharge member 3 includes a connecting ring 31 and a mesh cloth 32, the mesh cloth 32 is arranged at the bottom of the connecting ring 31 and closes the inner hole of the connecting ring 31, and the powder outlet hole 301 is the mesh of the mesh cloth 32, usually using The mesh cloth 32 with good powder passing property and not easy to stick to powder, the mesh cloth 32 and the connecting ring 31 can also be pasted together by high temperature, so that the connection is tighter and the stability is better, such as Figure 11 , Figure 12 As shown, that is, the shoulder cover 2 scheme one, the bottom of the shoulder cover 2 is provided with a second groove body 28 for placing the connecting ring 31, and the second groove body 28 is provided with a first groove matching the inner hole of the connec...

Embodiment 3

[0052] This implementation is a modification of the second embodiment, that is, the powder discharge member 3 and the shoulder cover 2 are defined in another way, specifically, as Figure 17 , Figure 18 As shown, the powder discharge member 3 includes a rotating disk 33, and several powder outlet holes 301 are evenly distributed on the rotating disk 33, as Figure 15 , Figure 16 As shown, in the second scheme of the shoulder cover 2, the bottom of the shoulder cover 2 is provided with a third tank 29 for arranging the turntable 33, and the third tank 29 is provided with a plurality of second through holes 291 that match the powder outlet holes 301. , during use, the turntable 33 is fixed in the third groove body 29, and the cosmetic powder in the container main body 1 can enter the powder coating space 22 through the second through hole 291 and the powder outlet hole 301, and contact with the cosmetic tool 4, thereby improving the cosmetic powder. The reliability of cosmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com