Red date potato chips and processing method

A technology for red dates and potato chips, which is applied in ultrasonic treatment of food, food ingredients as taste modifiers, food forming, etc., can solve problems such as single taste, shorten frying time, etc., reduce enzymatic browning, and increase cell penetration. Think, improve the effect of fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

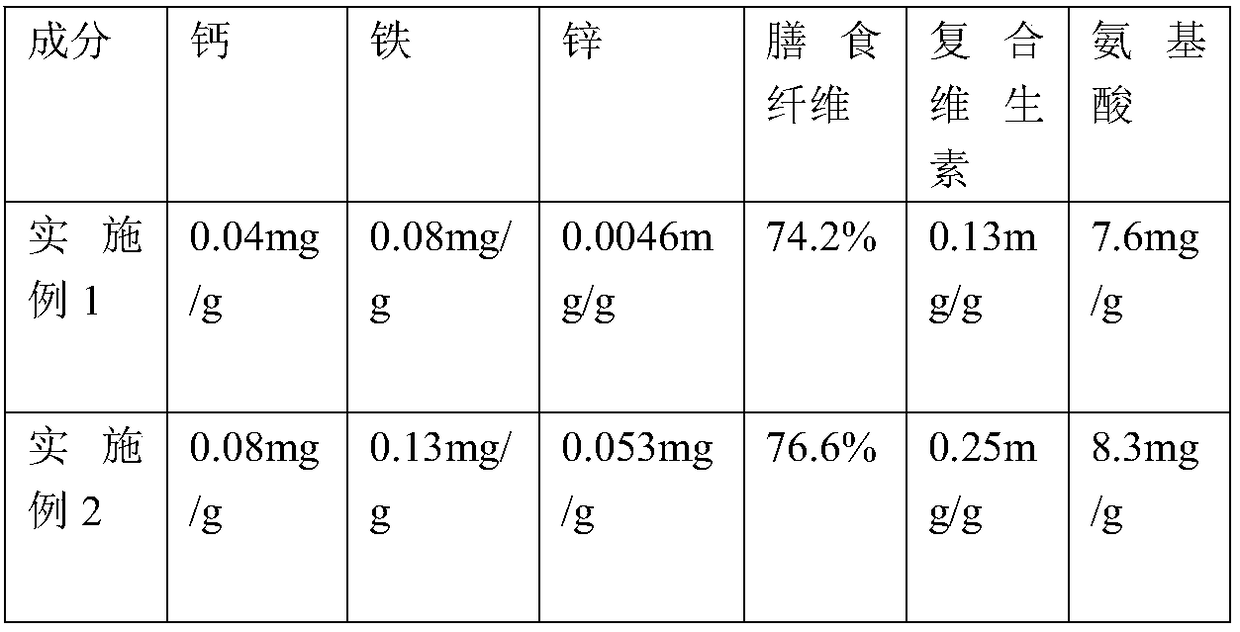

Embodiment 1

[0064] A kind of jujube potato chips, the processing method steps are as follows:

[0065] (1) Preparation of red date compound mud: 100 parts of red date powder, 100 parts of mashed potatoes, 50 parts of wolfberry powder are added to 50 parts of water to make thick muddy red date compound mud;

[0066] (2) compression molding: the red date compound mud in the step (1) is made into a plurality of thicknesses with a mold and is 0.05cm, and a diameter is a sheet of 5cm;

[0067] (3) steaming: put the thin slices in the step (2) into a steamer, and air-dry after the thin slices are steamed to make potato chips with a water content of 20%;

[0068] (4) Expansion: Quick-freeze the potato chips in step (3) at a low temperature of -40°C for 8 minutes, then store the quick-frozen potato chips at a temperature of -18°C for later use, and perform puffing processing, specific processing steps as follows:

[0069] ①Open the solenoid valve, connect the steam generator and the expansion t...

Embodiment 2

[0112] A kind of jujube potato chips, the processing method steps are as follows:

[0113] (1) Preparation of red date compound mud: 200 parts of red date powder, 150 parts of mashed potatoes, 80 parts of wolfberry powder are added to 80 parts of water to make thick muddy red date compound mud;

[0114] (2) compression molding: the red date composite mud in the step (1) is made into a plurality of thicknesses with a mold and is 0.2cm, and a diameter is a thin slice of 8cm;

[0115] (3) steaming: put the thin slices in the step (2) into a steamer, and air-dry after the thin slices are steamed to make potato chips with a water content of 20%;

[0116] (4) Expansion: Quick-freeze the potato chips in step (3) at a low temperature of -40°C for 10 minutes, then store the quick-frozen potato chips at a temperature of -18°C for later use, and perform puffing processing, specific processing steps as follows:

[0117] ①Open the solenoid valve, connect the steam generator and the expan...

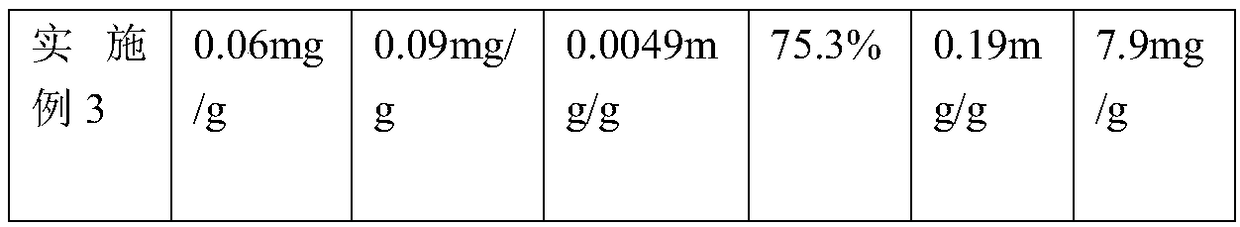

Embodiment 3

[0161] A kind of jujube potato chips, the processing method steps are as follows:

[0162] (1) Preparation of red date compound mud: 150 parts of red date powder, 130 parts of mashed potatoes, 70 parts of wolfberry powder are added to 65 parts of water to make thick muddy red date compound mud;

[0163] (2) compression molding: the red date composite mud in the step (1) is made into a plurality of thicknesses with a mold and is 0.01cm, and a diameter is a sheet of 7cm;

[0164] (3) steaming: put the thin slices in the step (2) into a steamer, and air-dry after the thin slices are steamed to make potato chips with a water content of 20%;

[0165] (4) Expansion: Quick-freeze the potato chips in step (3) at a low temperature of -40°C for 9 minutes, then store the quick-frozen potato chips at a temperature of -18°C for later use, and perform puffing processing, specific processing steps as follows:

[0166] ①Open the solenoid valve, connect the steam generator and the expansion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com