A kind of control method of egr valve of diesel engine

A technology of EGR valve and control method, which is applied in engine control, electrical control, fuel injection control, etc., can solve the problems of EGR valve control accuracy drop, and achieve the effect of increasing work reliability and control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

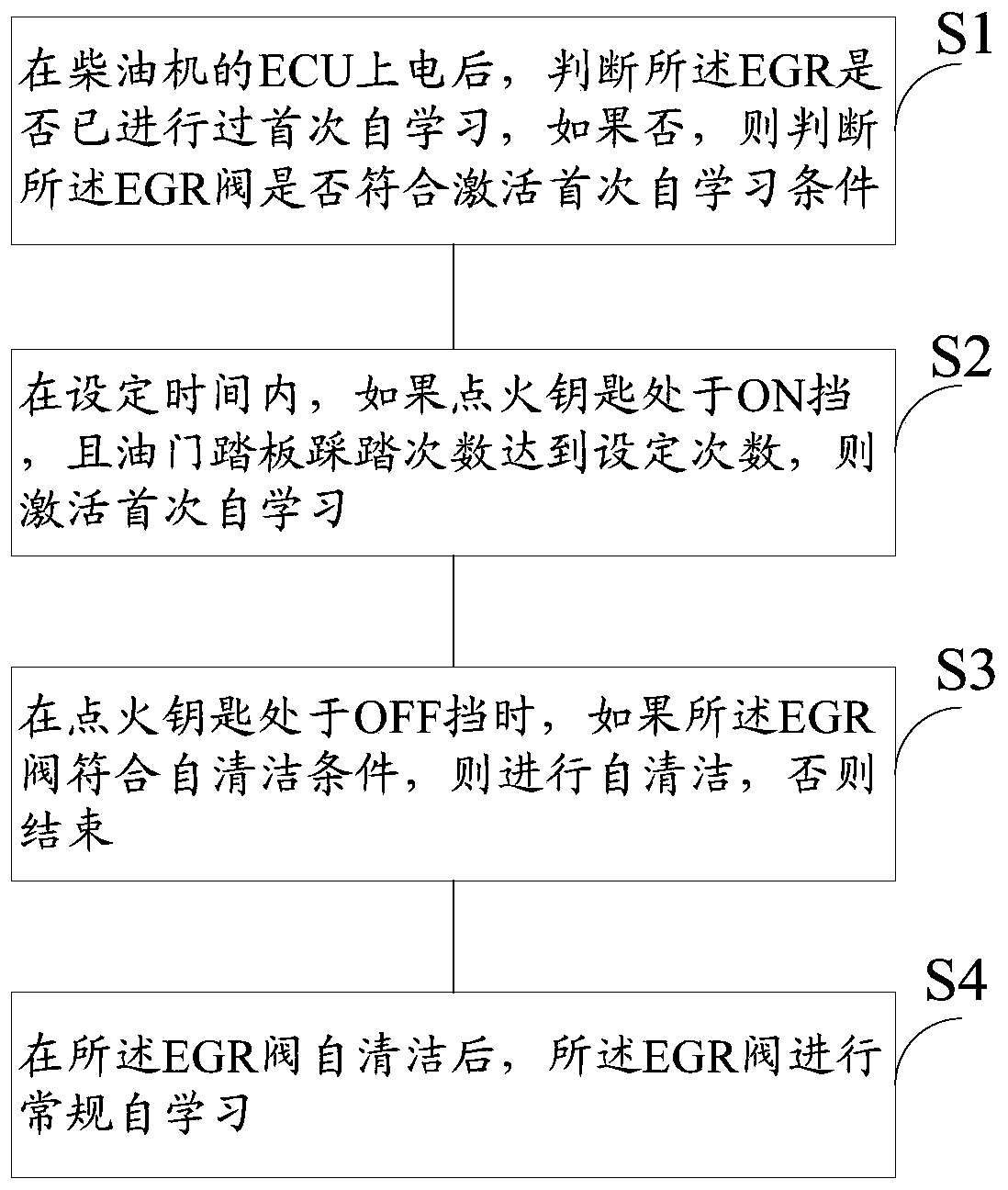

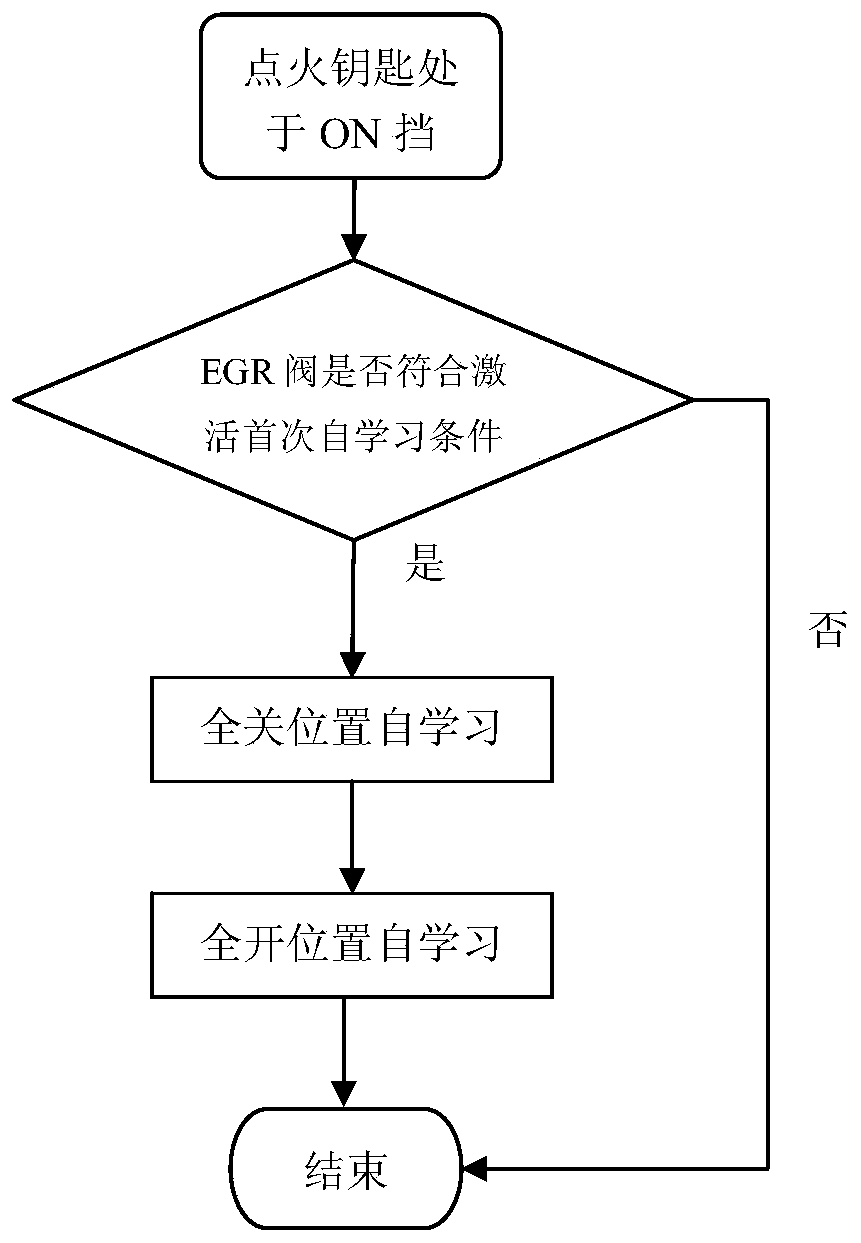

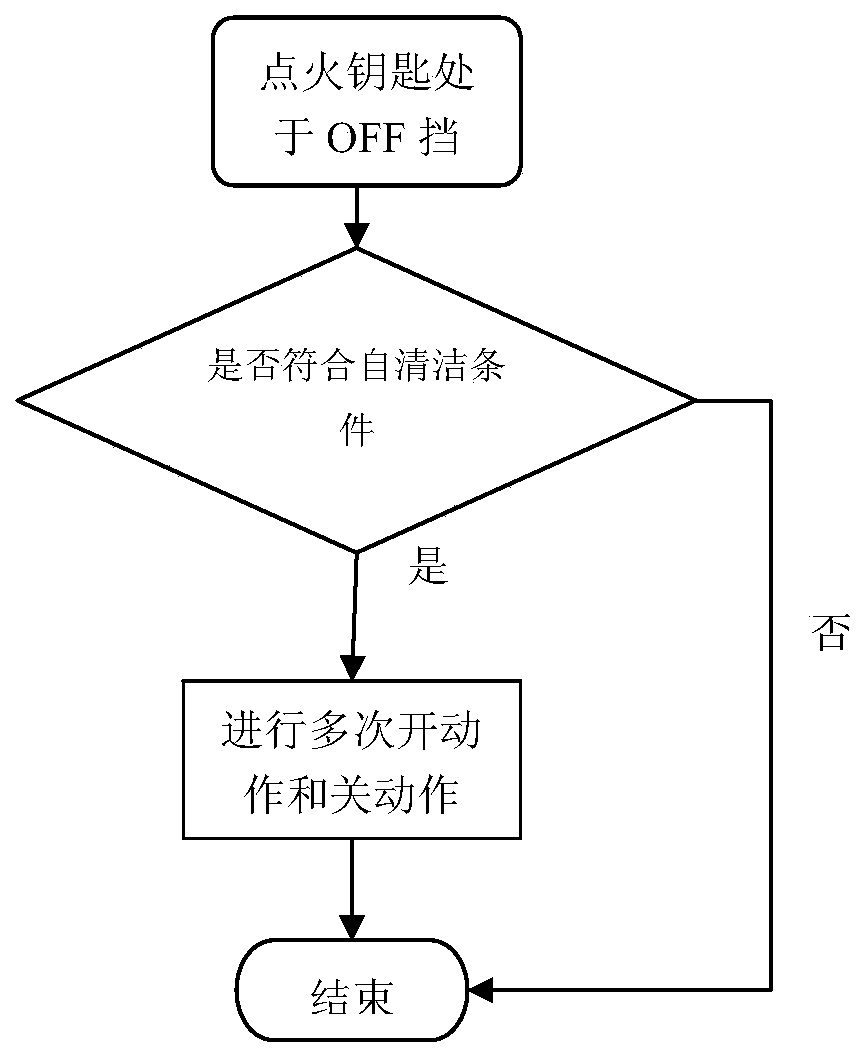

[0046] For the EGR valve of the current engine, it is easy to cause zero drift and control accuracy drop due to carbon deposits and high-temperature exhaust gas. The invention provides a method for controlling the EGR valve of a diesel engine. The first self-learning is performed by controlling the EGR valve when the power is turned on, and self-cleaning and conventional self-learning are performed on the EGR valve when the power is turned off, so that the full-close position and the full-open position of the EGR valve can be adjusted accordingly. The zero point position is kept accurate, which solves the problem that the zero point of the EGR valve of the existing diesel engine EGR valve drifts due to carbon dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com