Velocity synchronous loading decoupling method and device for structural test system

A technology for structural testing and decoupling devices, which is applied in general control systems, testing of machines/structural components, measuring devices, etc., and can solve problems such as decreased control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

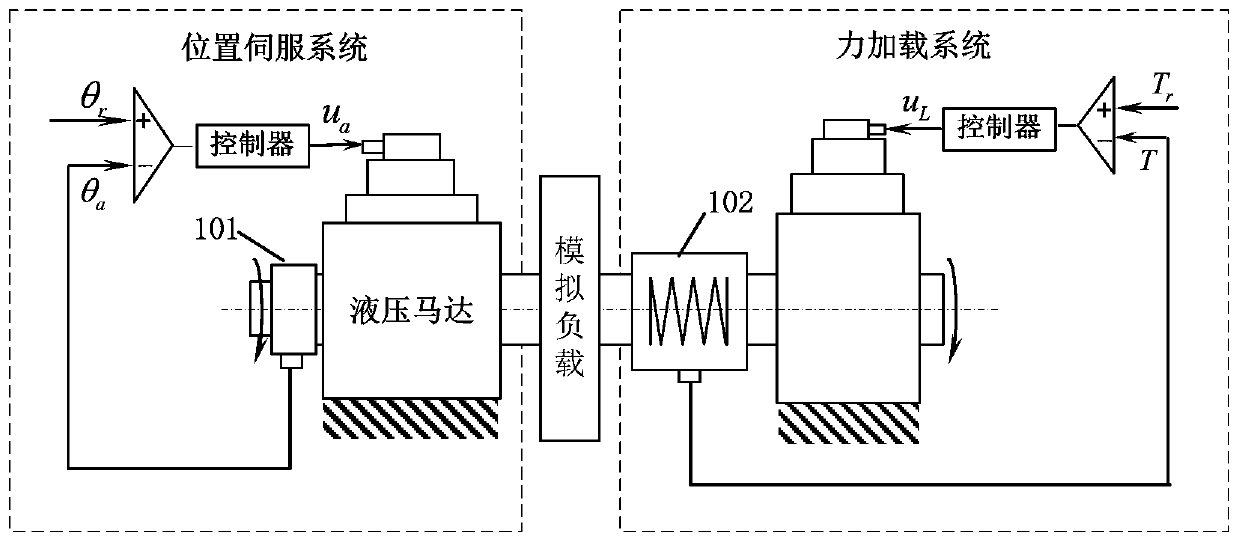

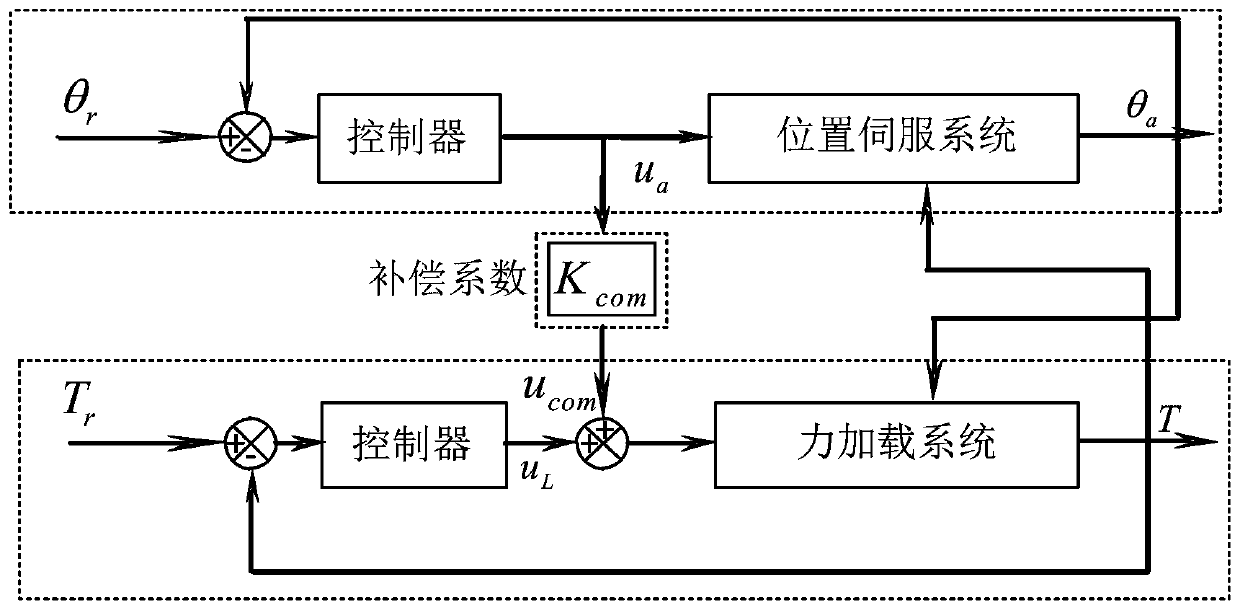

[0031] The velocity synchronous loading and decoupling method and device for a structural test system according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

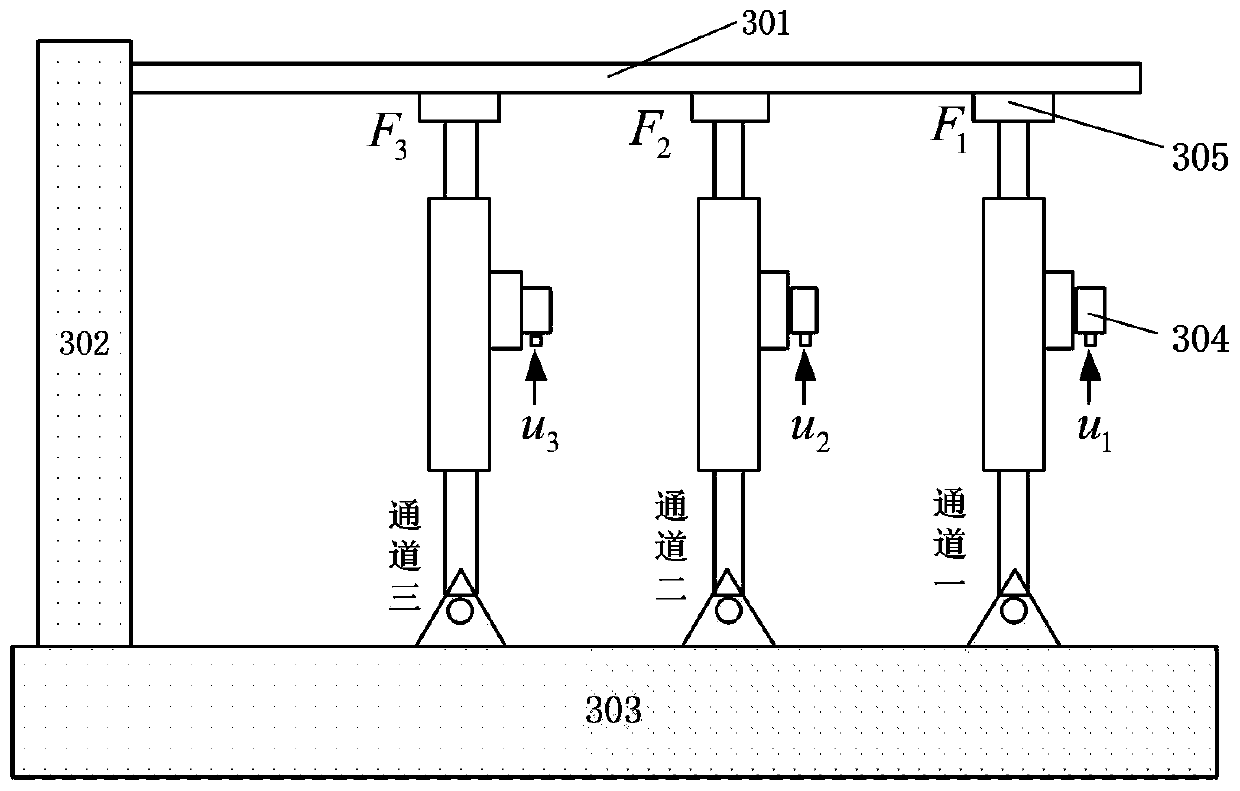

[0032] image 3 A structural testing system is shown having multiple loading channels in accordance with an embodiment of the invention. To simplify the description, image 3 Only three loading channels are shown in , and the cantilever beam is loaded by a valve-controlled cylinder. Such as image 3 As shown, a cantilever beam 301 as a bearing object is fixed on a base 303 through a supporting wall 302 . where u i (i=1, 2, 3) represents the control signal from the servo valve 304 on each loading channel, F i (i=1, 2, 3) represent the force signals collected by the force sensors 305 on the respective loading channels.

[0033] Specifically, when a certain loading channel i (i=1, 2, 3) applies a load F to the cantilever beam 301 i , the cant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com