Intermediate cloth splicing method

A cloth strip and cloth technology, which is applied in the field of garment manufacturing, can solve the problems such as the inability to realize the simultaneous operation of piping and stitching, and achieve the effects of simple structure, convenient use and good adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through specific embodiments.

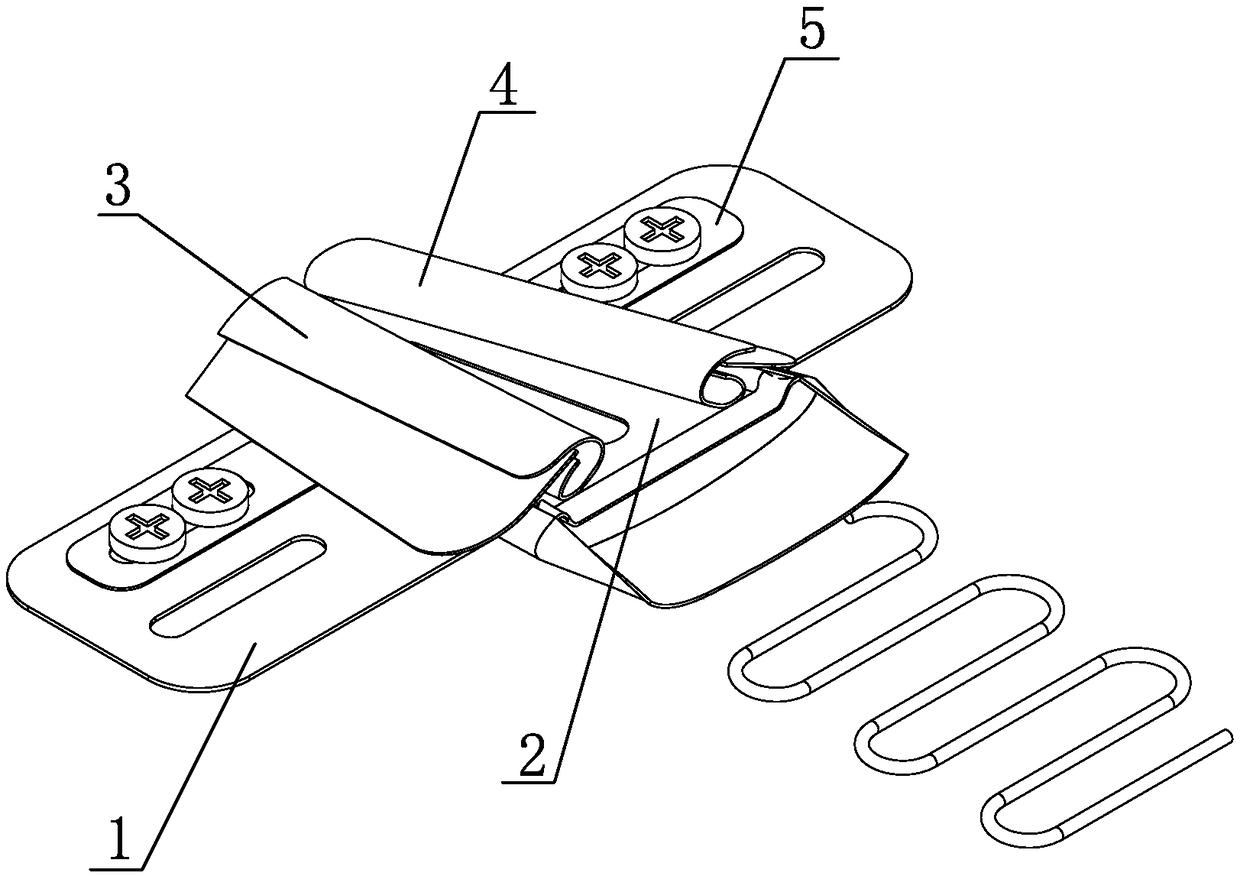

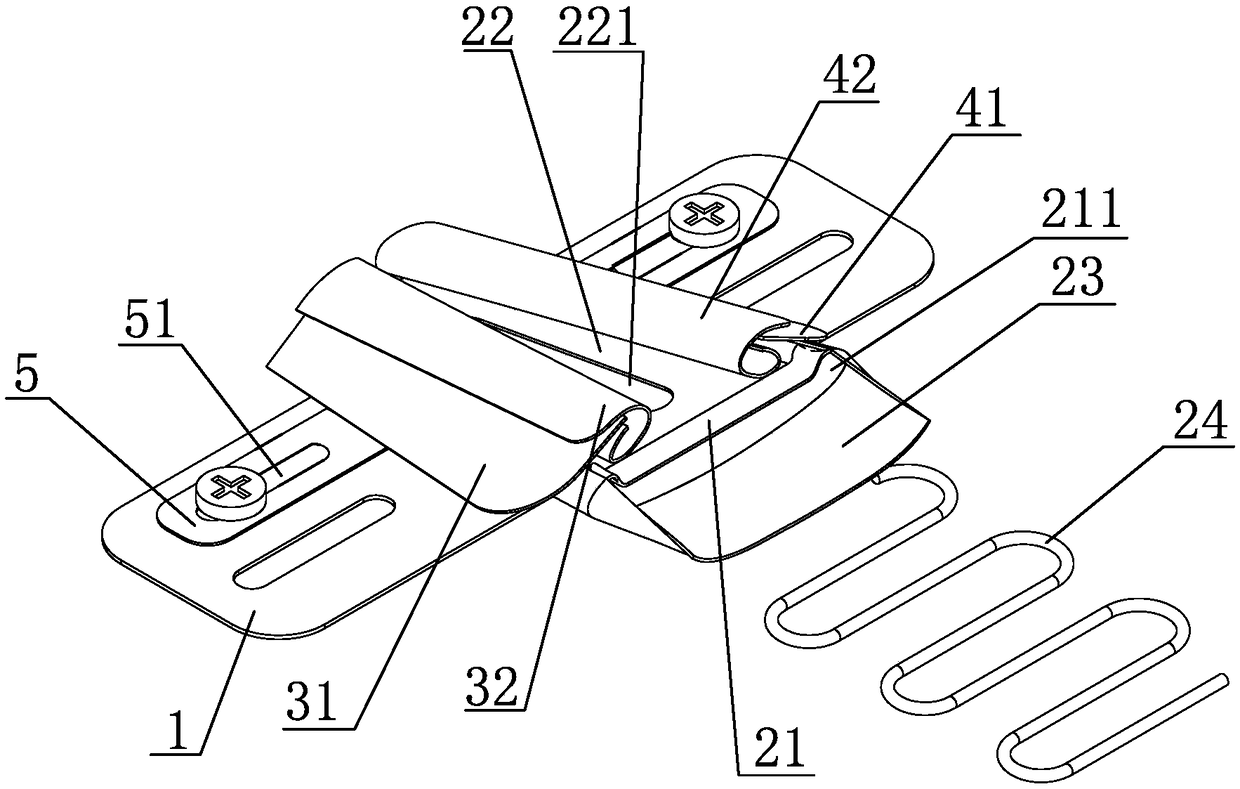

[0026] refer to Figure 1 to Figure 5 As shown, a quilting halter in the middle includes a base plate 1, a quilting strip hemming device 2, a left hemming device 3, a right hemming device 4 and a connecting plate 5;

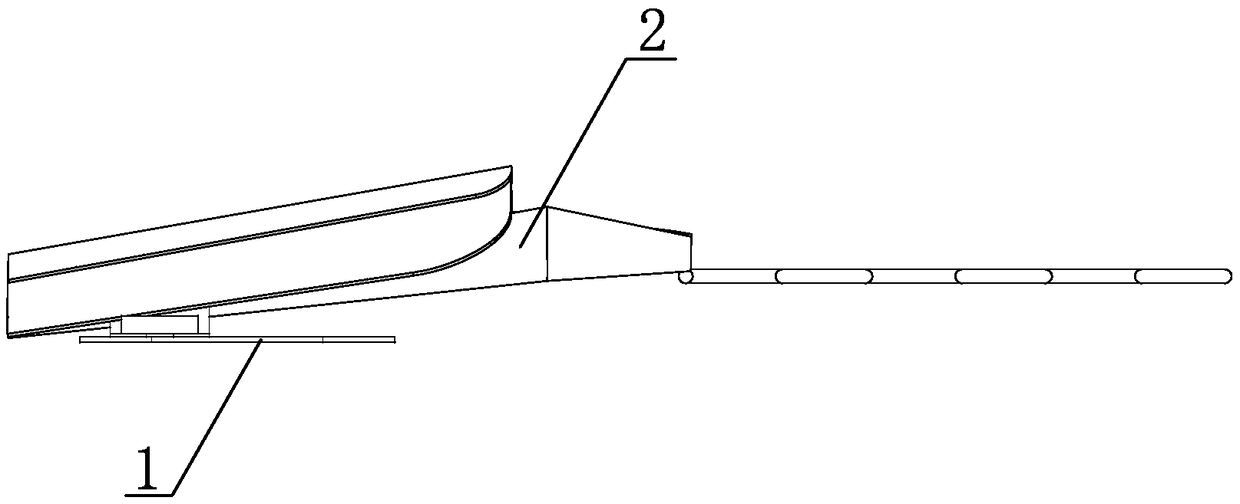

[0027] The bottom plate 1 is connected to the patchwork strip curling device, and the patchwork strip curling device forms an angle of 5-45° with the bottom plate;

[0028] The quilting strip crimping device 2 includes a conical cylinder 21, a pressing plate 22, a feed channel 23 and a quilting strip guide rod 24. The two ends of the conical cylinder 21 are cloth inlet and cloth outlet respectively, and the conical cylinder 21 Gradually shrink and gather from the cloth inlet to the cloth outlet. The left and right sides of the tapered cylinder 21 are respectively provided with a cloth rolling channel 211 bent toward the axis of the tapered cylinder 21. The pressing plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com