Lifting ejection rod with screw rod

A technology of ejector rods and screw rods, applied in the direction of lifting devices, etc., can solve the problems of easy failure of the mechanism, difficult maintenance work, high cost, etc., and achieve the effect of high operational reliability of the mechanism, low difficulty of maintenance work, and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

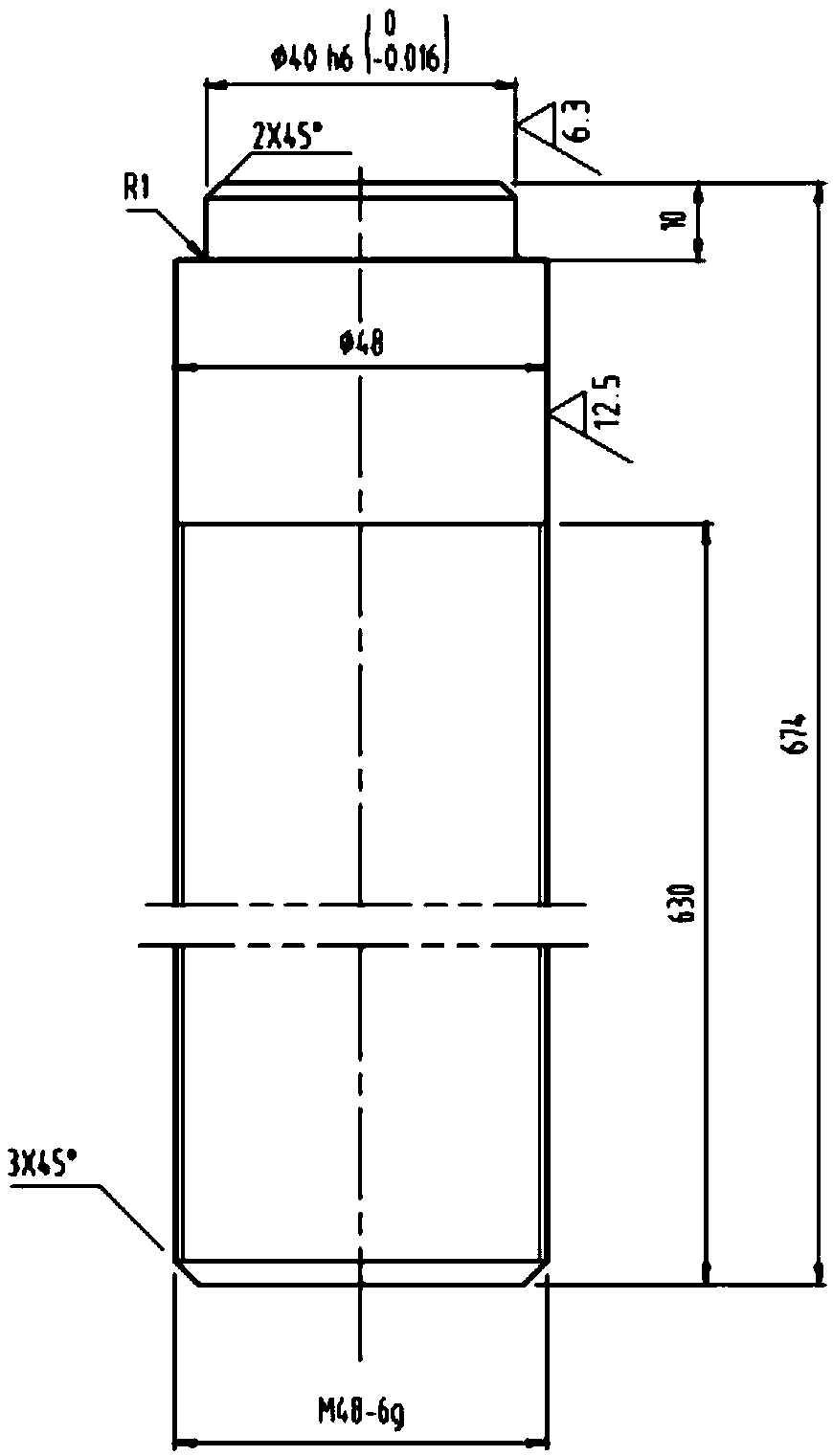

[0008] The screw lifting ejector rod is composed of three parts: the screw, the polished rod and the ejector head. The screw is in the lower part, the polished rod is in the middle, and the ejector head is in the upper part. The outer diameter of the lead screw is equal to that of the polished rod. The parameters of the lead screw are M48 thread and 630mm in length; the outer diameter of the polished rod is ¢48mm and the length is 34mm; A fixed nut cooperates, and the head of the ejector rod cooperates with the center hole of the lifting frame. When the screw is rotated, the screw moves up and down along the helical line of the nut, thereby jacking up or lowering the object.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com