High-efficiency composite braking mode alternating current frequency conversion winch and lowering control method thereof

A technology of AC frequency conversion and mode, which is applied in the direction of hoisting device and clockwork mechanism, etc., can solve the problems of electric control system impact, energy cannot be released quickly, and easy to cause failure, etc., achieve high safety, save drilling time, The effect of high overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

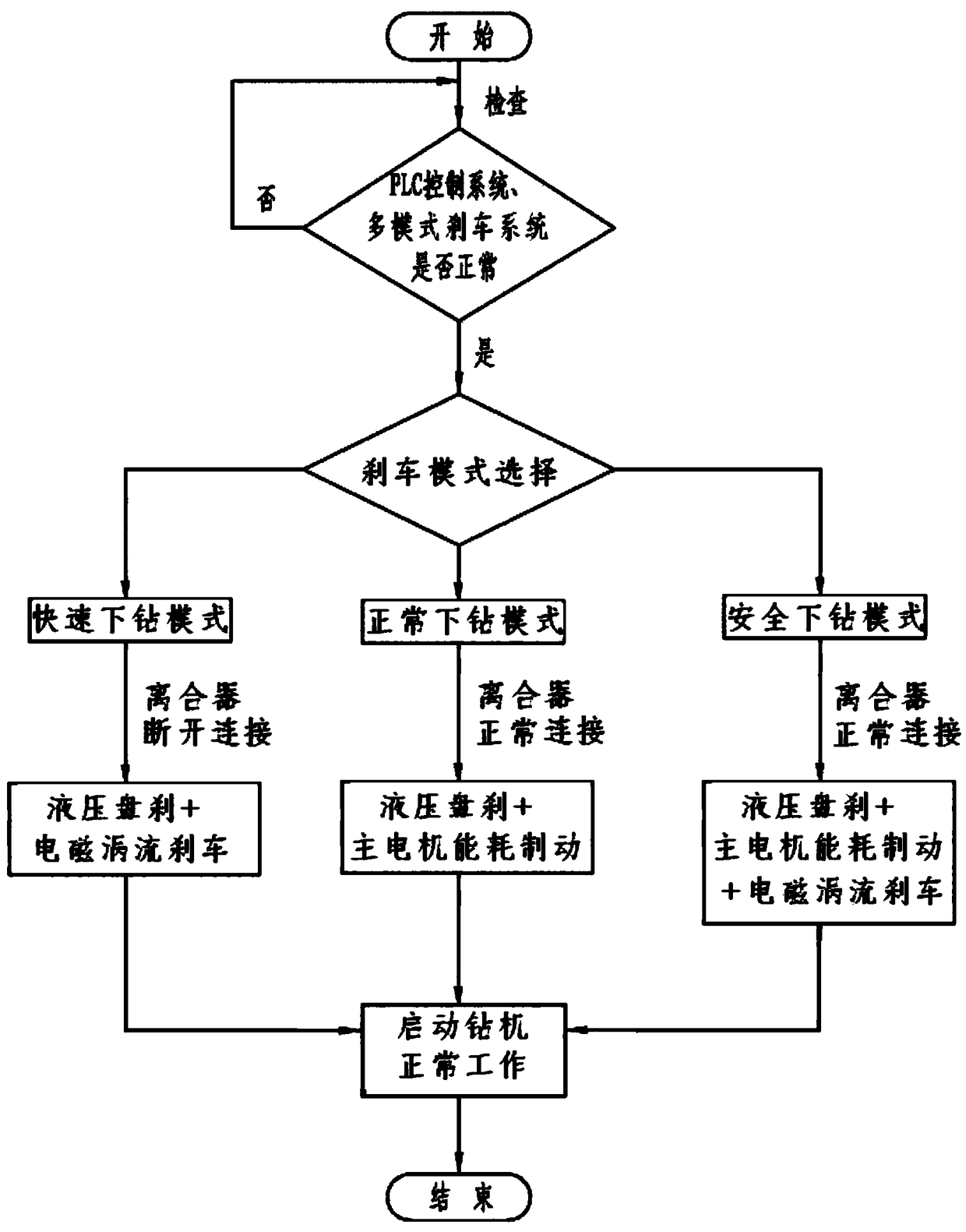

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

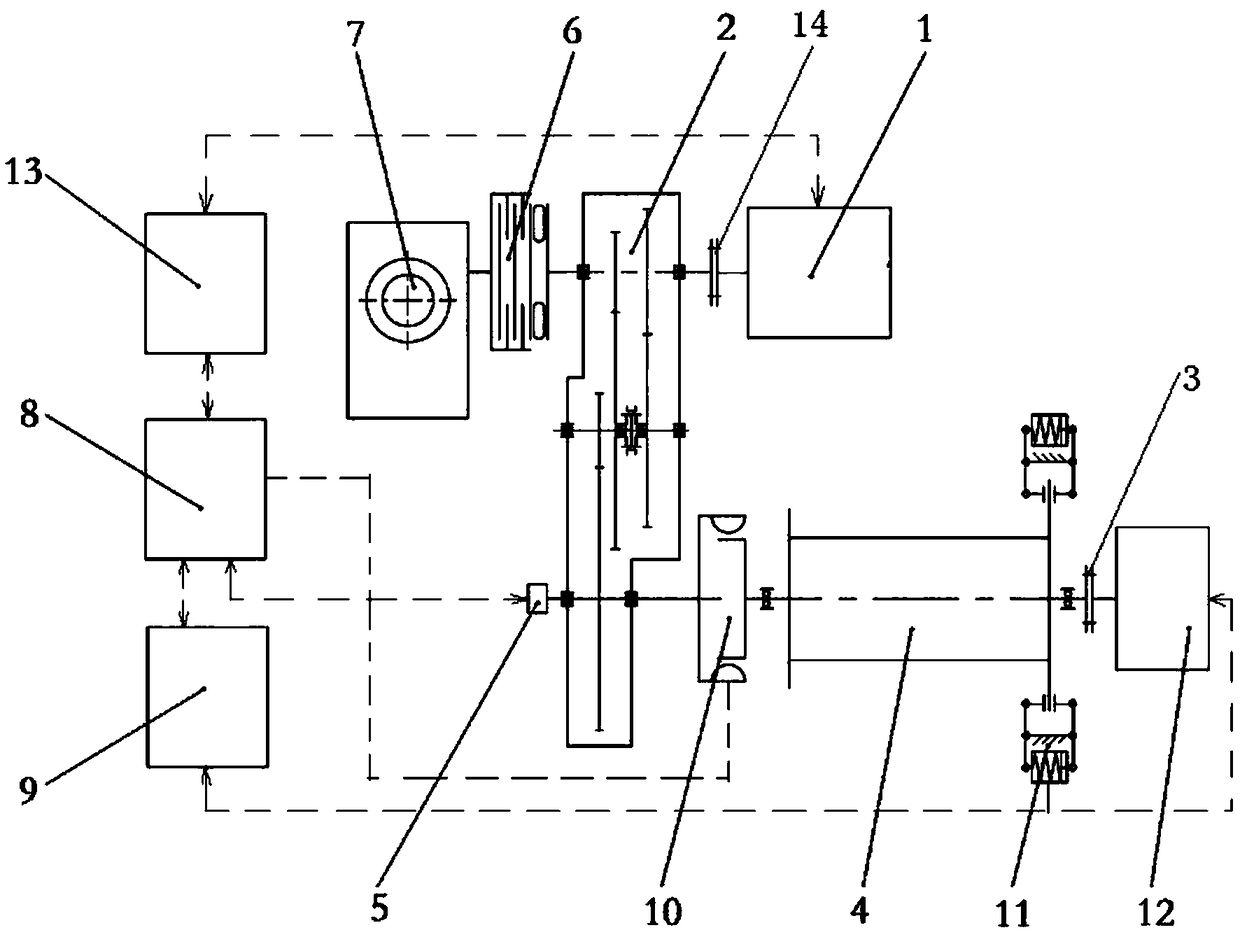

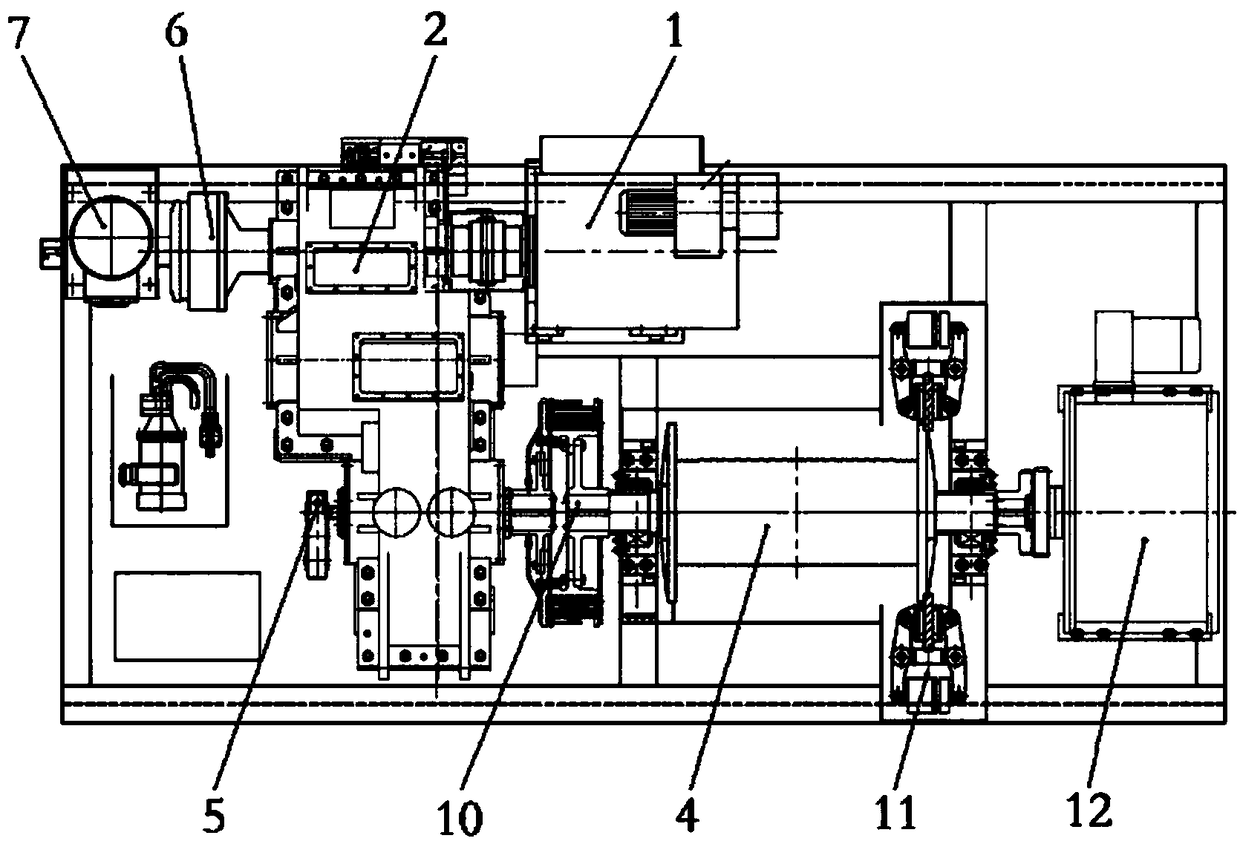

[0027] The present invention is a high-efficiency compound braking mode AC variable frequency winch, such as figure 1 , figure 2 As shown, the automatic drilling device 7 is included, the automatic drilling device 7 is connected to the gearbox 2 through the push plate clutch 6, the gearbox 2 is connected to the AC frequency conversion main motor 1 through the first coupling 14, and the gearbox 2 is also connected to the The clutch 10 is connected with the drum shaft assembly 4, the drum shaft assembly 4 is connected with the electromagnetic eddy current brake 12 through the second coupling 3 or the drum shaft of the drum shaft assembly 4 is connected with the electromagnetic eddy current brake 12 through the key, and the electromagnetic eddy current brake A hydraulic disc brake 11 is connected between 12 and the drum shaft assembly 4 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com