Correcting device for rectangular plate splicing

A correction device and a rectangular plate technology, applied in the field of sheet metal welding, can solve the problems of low efficiency, time-consuming and labor-intensive, and low welding seam adjustment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

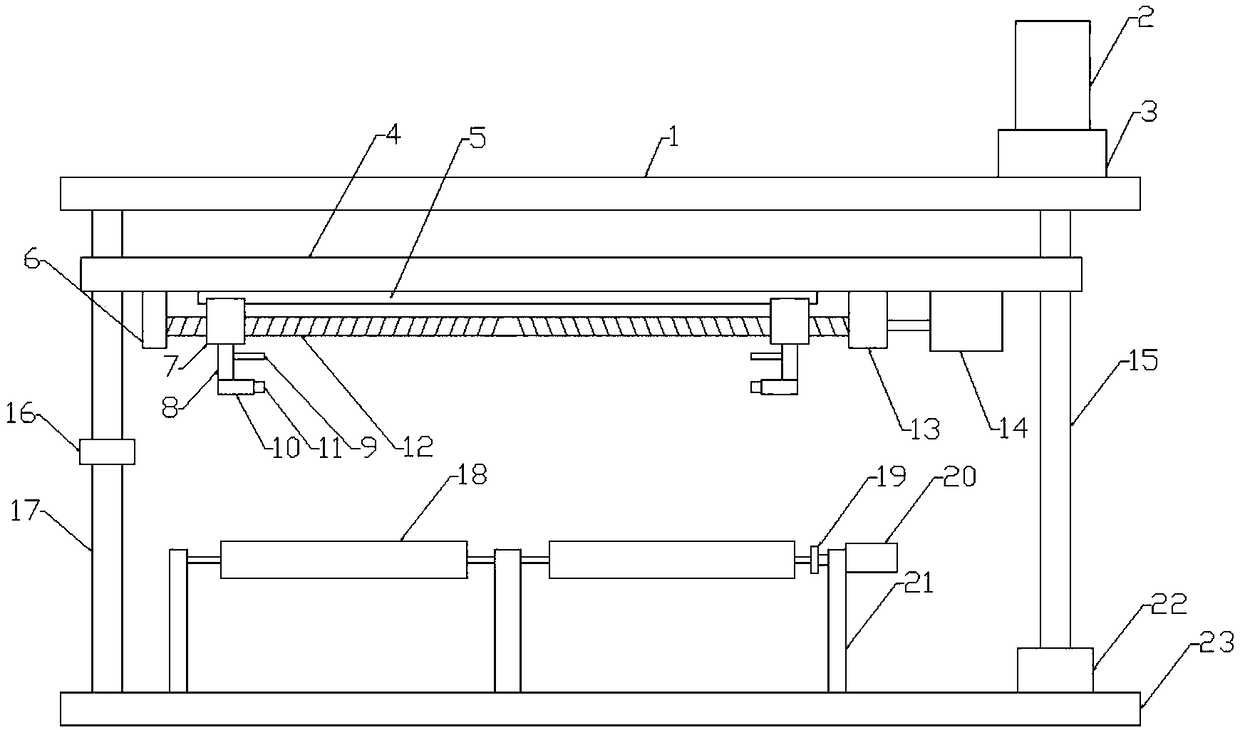

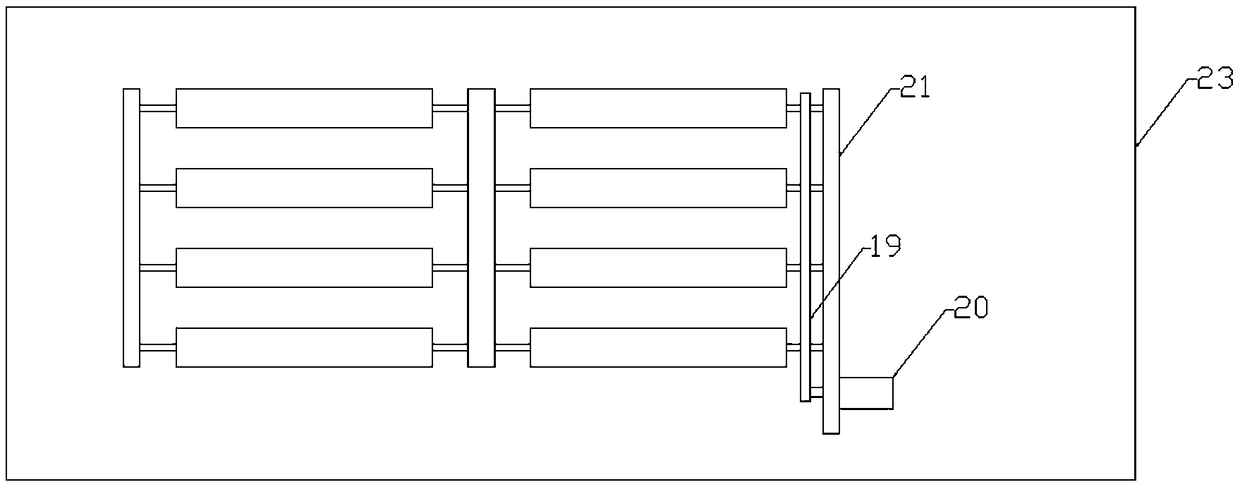

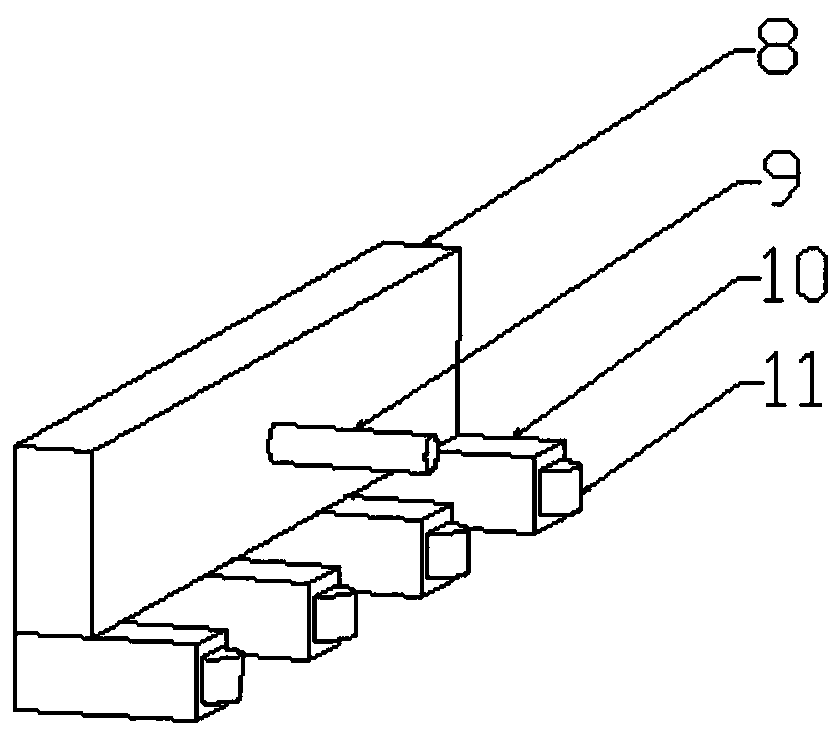

[0014] Figure 1-3 A specific embodiment of the present invention is shown: a correction device for splicing rectangular plates, including a top plate 1 and a bottom plate 23, a support 21 is provided in the middle of the bottom plate 23, and a plurality of rollers 18 are uniformly arranged on the support 21, so that A transmission motor 20 is fixed on the side of the support 21, the transmission motor 20 is connected with the roller 18 through a transmission belt 19, a slide bar 17 is fixed at one end of the bottom plate 23, and the other end of the slide bar 17 is fixed on the top plate 1, the Bottom plate 23 other ends are fixed with screw mandrel supporting seat-22, and described top plate 1 upper end is provided with motor driving seat-3, and described motor driving seat-3 and screw mandrel supporting seat-22 are provided with screw mandrel 15, and described motor driving seat-3 and screw mandrel supporting seat-22 are provided with screw mandrel 15, and The stepping moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com