A motor damping base with multiple vibration structures

A multi-vibration, motor-seat technology, applied in the direction of shock absorbers, shock absorbers, electric components, etc., can solve the problems of amplitude vibration, looseness, noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

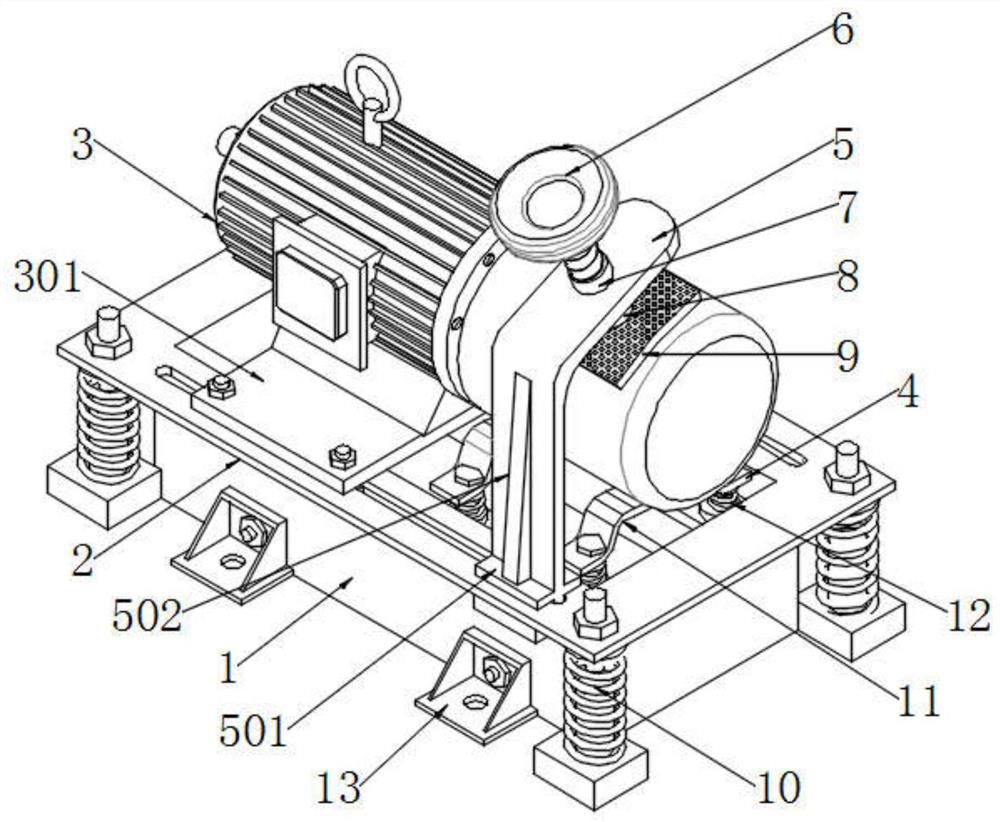

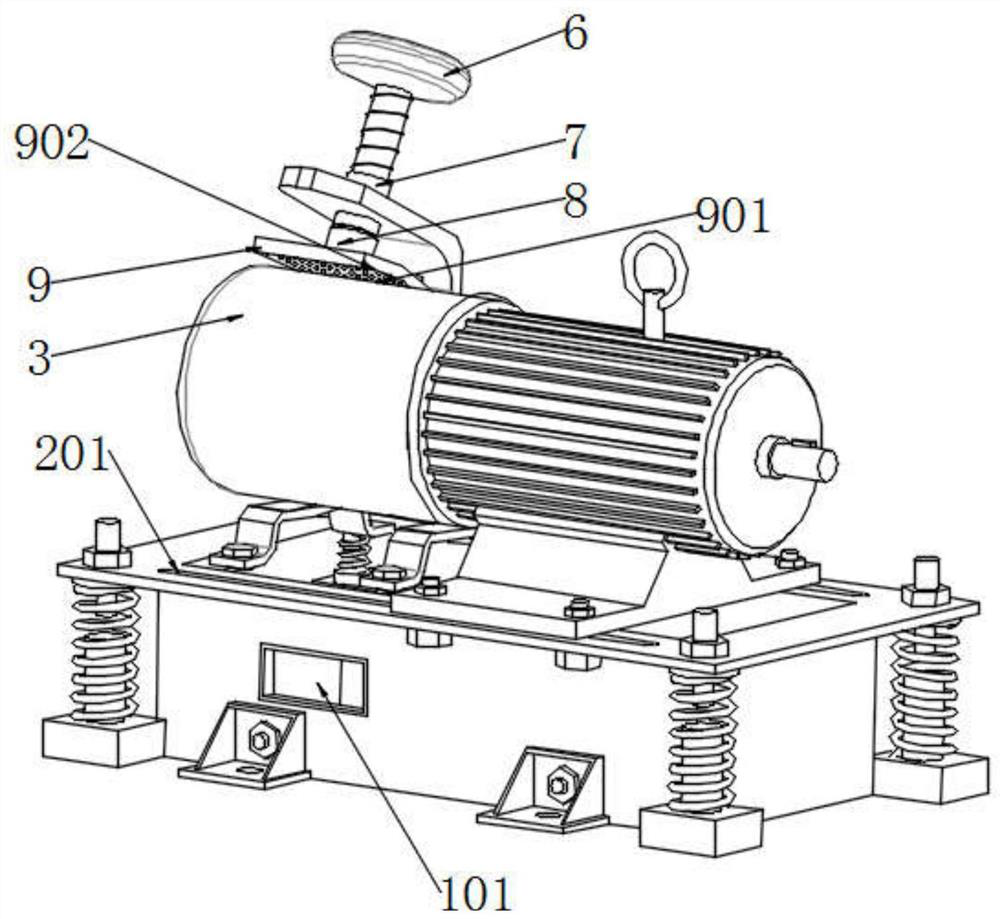

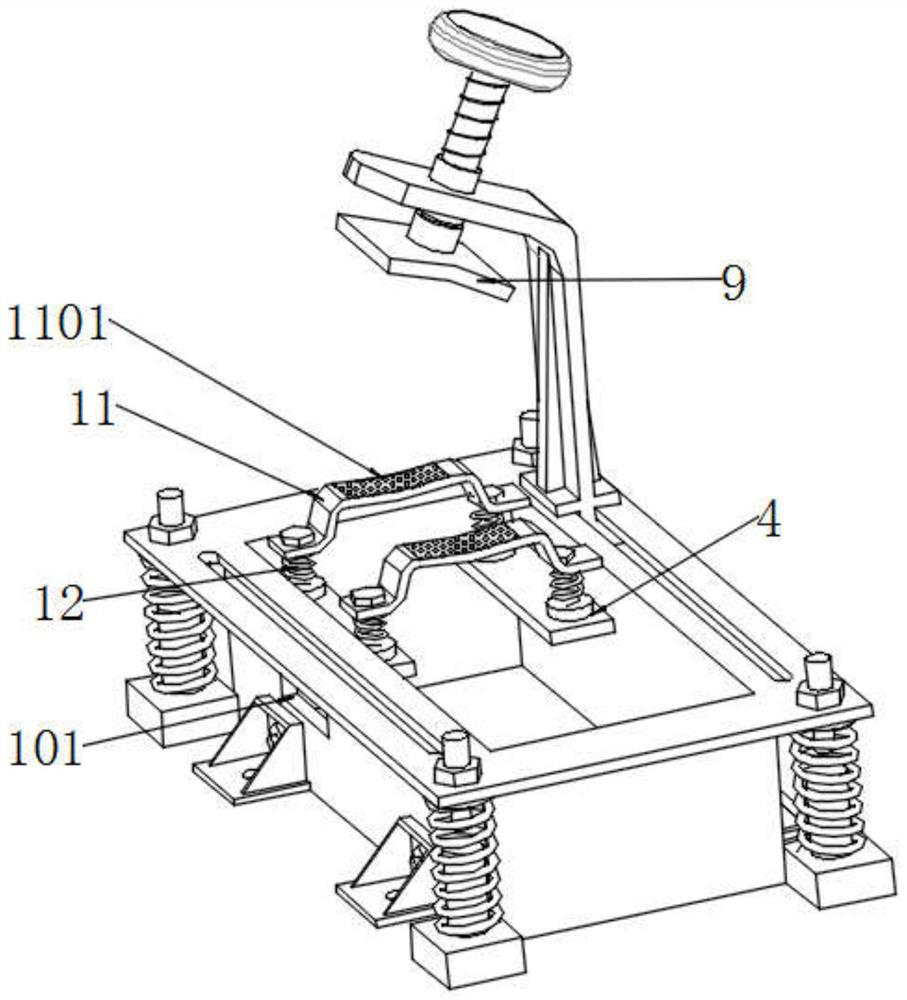

[0035] as attached figure 1 To attach Figure 8 Shown:

[0036]The present invention provides a motor damping base with a multi-vibration structure, including a base body 1, a reserved hole 101, a mounting plate 2, a chute 201, for example a motor 3, a motor seat 301, a support plate 4, a pressure plate 5, a sliding Block 501, reinforcement plate 502, large bolt 6, threaded sleeve 7, shaft sleeve 8, top plate 9, first air hole 901, first corrugated section 902, first spring seat 10, pad 11, second air hole 1101, The second corrugated section 1102, the second spring seat 12 and the foot 13; the base body 1 is a cavity structure with a rectangular structure, and a mounting plate 2 is provided on the outer edge of the rectangular top opening, and through this mounting plate 2 Opened, the chute 201 is bolted to a motor seat 301 of an example motor 3 illustrated; the four corners of the base body 1 are equipped with a first spring seat 10, and these first spring seats 10 The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com