A black and white multi-shaped perforation linear slit type naked-view 3D imaging film

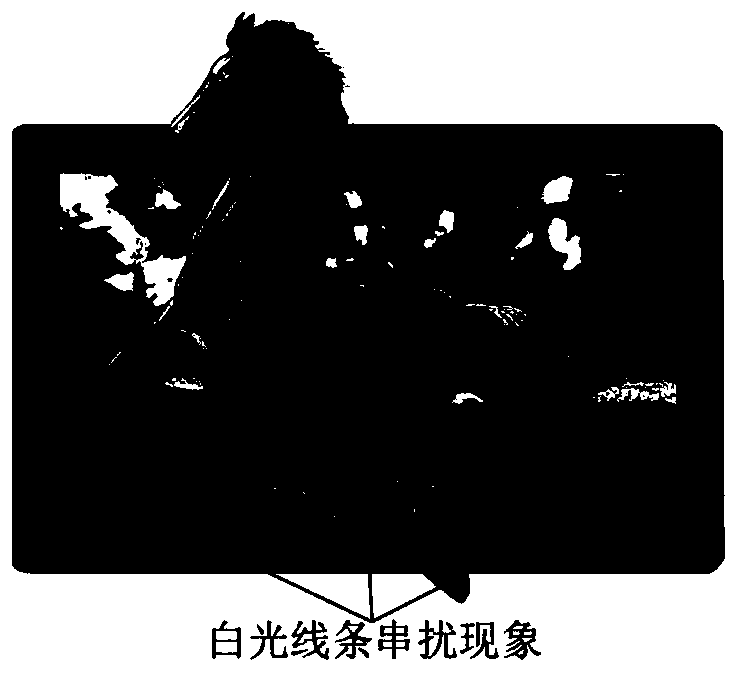

A linear and slit-type technology, applied in the field of optical imaging film, can solve problems such as reduced screen brightness, no obvious effect on pixel accuracy, and low resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

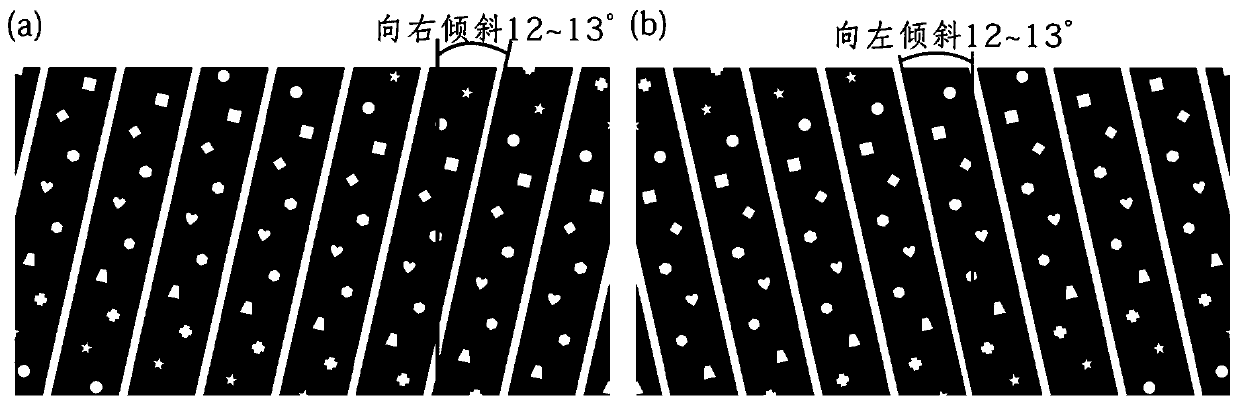

[0089] A black-and-white decagonal single-hole linear slit-type naked-view 3D imaging film, specially corresponding to the imaging unit module or sub-pixel with a resolution of 3840x2160 and a sub-pixel of about 28 inches in the vertical stripe structure of red, green and blue three primary colors It is a liquid crystal or plasma photoelectric display screen composed of red, green, blue, yellow (or white) four-color field-shaped display unit modules.

[0090] Such as Figure 21 (a) or Figure 23 As shown in (a), it is a schematic diagram corresponding to the overlapping of the black-and-white decagonal single-hole linear slit naked-view 3D imaging module and the liquid crystal or plasma photoelectric display screen. The dimensions of the four edges of the two films and the outline of the screen are equal. The area is the same; the black-and-white decagonal single-hole linear slit-type naked-view 3D imaging module consists of several such as Figure 21 (c) or Figure 23 The ...

Embodiment 2

[0097] A black-and-white octagonal double-hole linear slit-type naked-view 3D imaging film, specially corresponding to a 3840x2160 resolution of about 28-inch sub-pixels with sub-pixels of red, green, blue, yellow (or white) four-color vertical strip structure A liquid crystal or plasma photoelectric display screen composed of like unit modules.

[0098] Such as Figure 22 As shown in (a), it is a schematic diagram corresponding to the overlapping of black and white octagonal double-hole linear slit naked-view 3D imaging module and liquid crystal or plasma photoelectric display screen. The dimensions of the four edges of the two films and the outline of the screen are equal. The area is the same; the black-and-white octagonal double-hole linear slit-type naked-view 3D imaging module consists of several such as Figure 22 (c) The black-and-white octagonal double-hole linear slit-type naked-view 3D display unit module shown in (c) is composed of coherent up and down sequentiall...

Embodiment 3

[0105]A black-and-white octagonal double-hole linear slit-type naked-view 3D imaging film, specially corresponding to the imaging unit module or sub-pixel with a resolution of about 55 inches of 3840x2160 and three primary colors of red, green and blue. It is a liquid crystal or plasma photoelectric display screen composed of red, green, blue, yellow (or white) four-color field-shaped display unit modules.

[0106] Such as Figure 24 (a) or Figure 26 As shown in (a), it is a schematic diagram corresponding to the overlapping of black and white octagonal double-hole linear slit naked-view 3D imaging module and liquid crystal or plasma photoelectric display screen. The dimensions of the four edges of the two films and the outline of the screen are equal. The area is the same; the black-and-white octagonal double-hole linear slit-type naked-view 3D imaging module consists of several such as Figure 24 (c) or Figure 26 (c) The black-and-white octagonal double-hole linear slit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com