Triaxial test rock sample stripper for rocks

A triaxial test and demoulding device technology, which is applied in the preparation, sampling and instrumentation of test samples, can solve the problems of failure to obtain rock sample damage cracks, unstable base frame of the demoulding device, secondary damage of rock samples, etc. , to achieve the effect of shortening the test period, small damage to rock samples, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with embodiment with reference to accompanying drawing:

[0024] The diameter of triaxial test rock sample specimen should be 48mm~54mm, and the ratio of sample height and diameter should be 2.0~2.5, and the rock sample that generally uses is diameter 50mm, and height 100mm takes this as an example to carry out demoulding device of the present invention Further clarification.

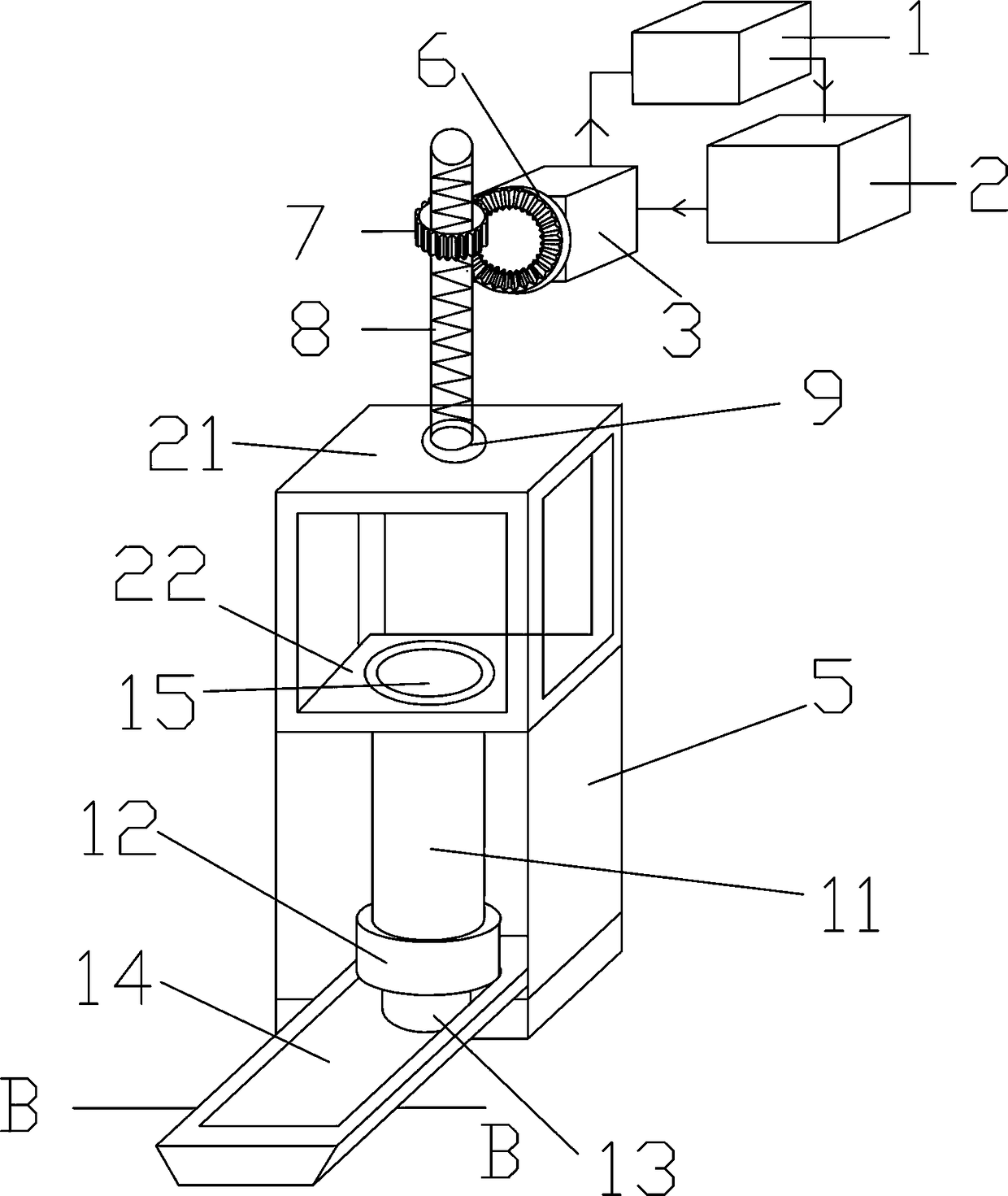

[0025] Such as Figure 1-5 As shown, the triaxial test rock sample demoulding device includes a compression mold part, a protection part, and a sample protection part;

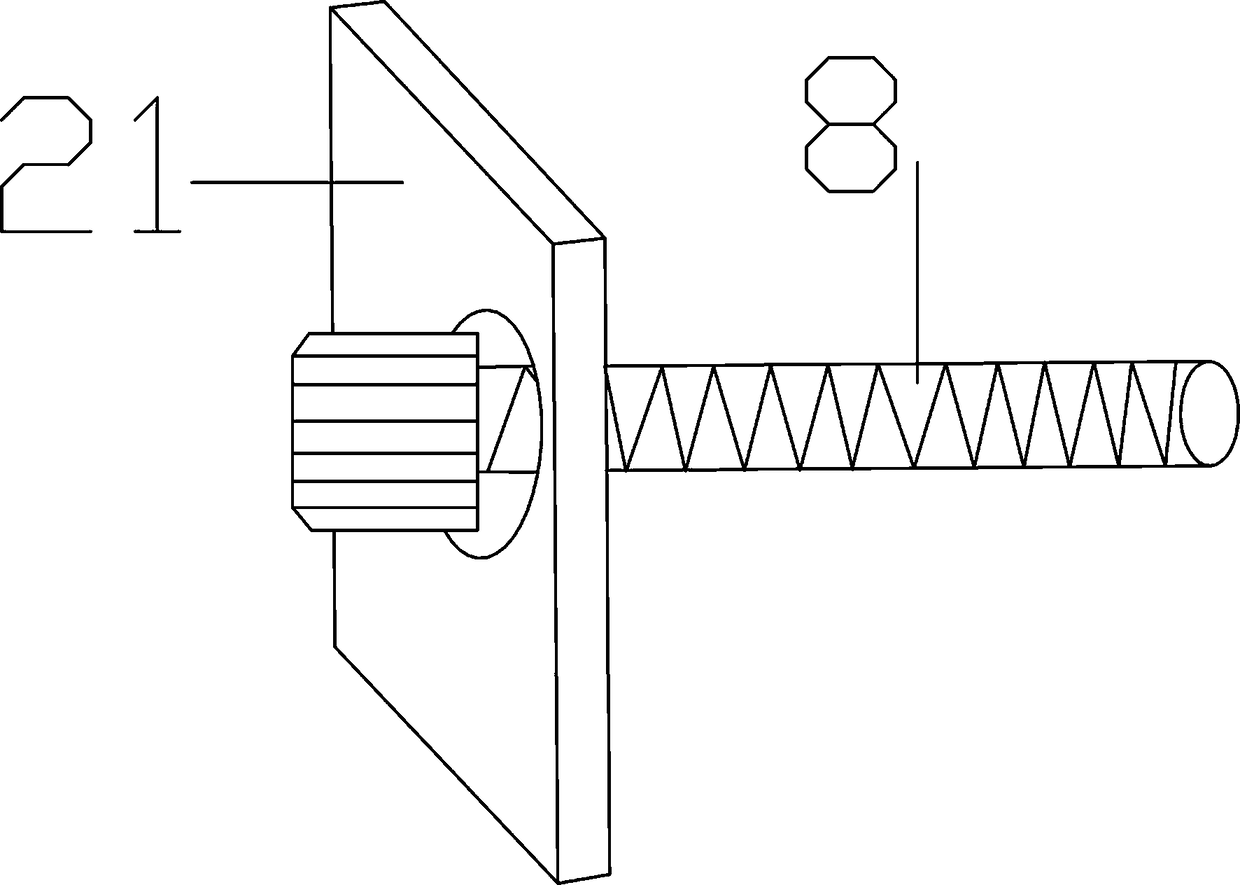

[0026] The protective part includes a base frame 5 with two ends open and a triaxial pressure chamber resting layer 22 arranged on the upper end of the base frame 5, and the top gasket 21 is connected to the upper surface of the triaxial pressure chamber resting layer 22 through a bracket;

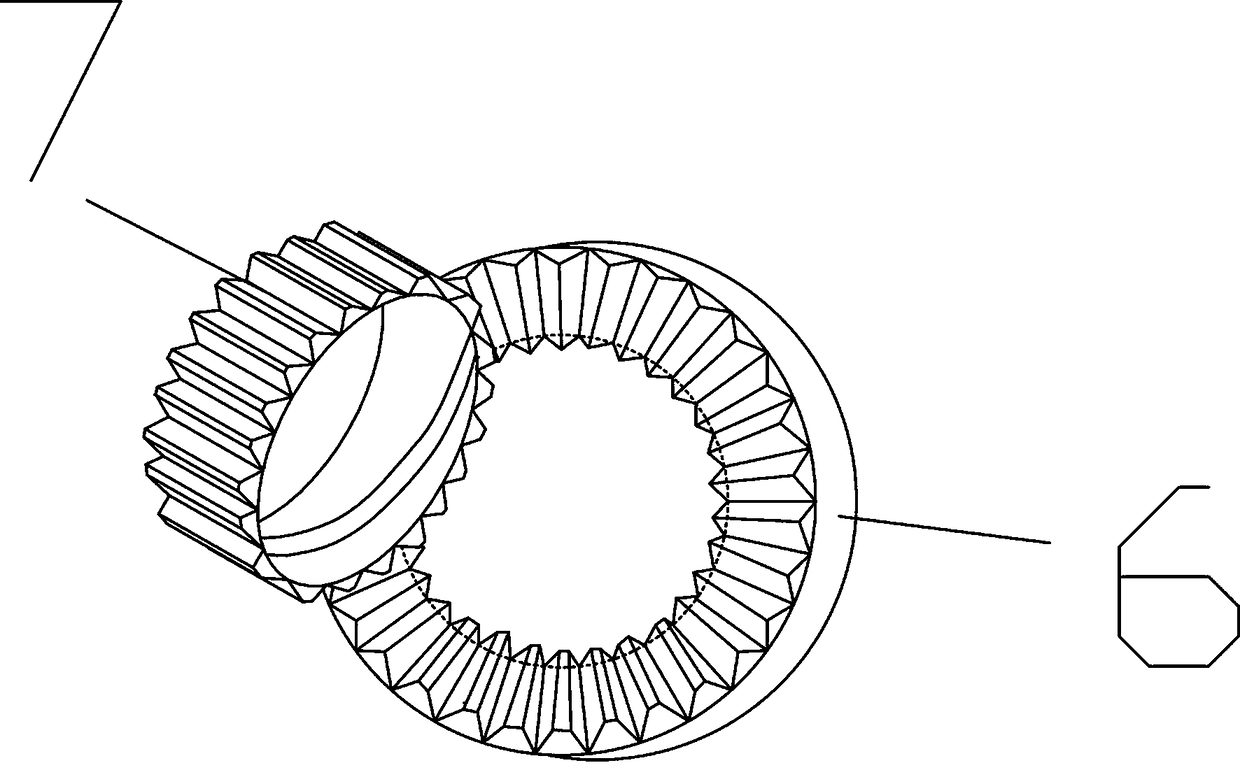

[0027] The die part includes a die threaded rod 8 with one end pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com