Novel flow guide groove structure for cabinet inner machine

A technology of diversion tanks and cabinet units, which can be used in household heating, condensation prevention, lighting and heating equipment, etc., and can solve problems such as short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in further detail below through specific examples, but it must be pointed out that the following examples are only used to describe the content of the invention, and do not constitute limitations to the protection scope of the present invention.

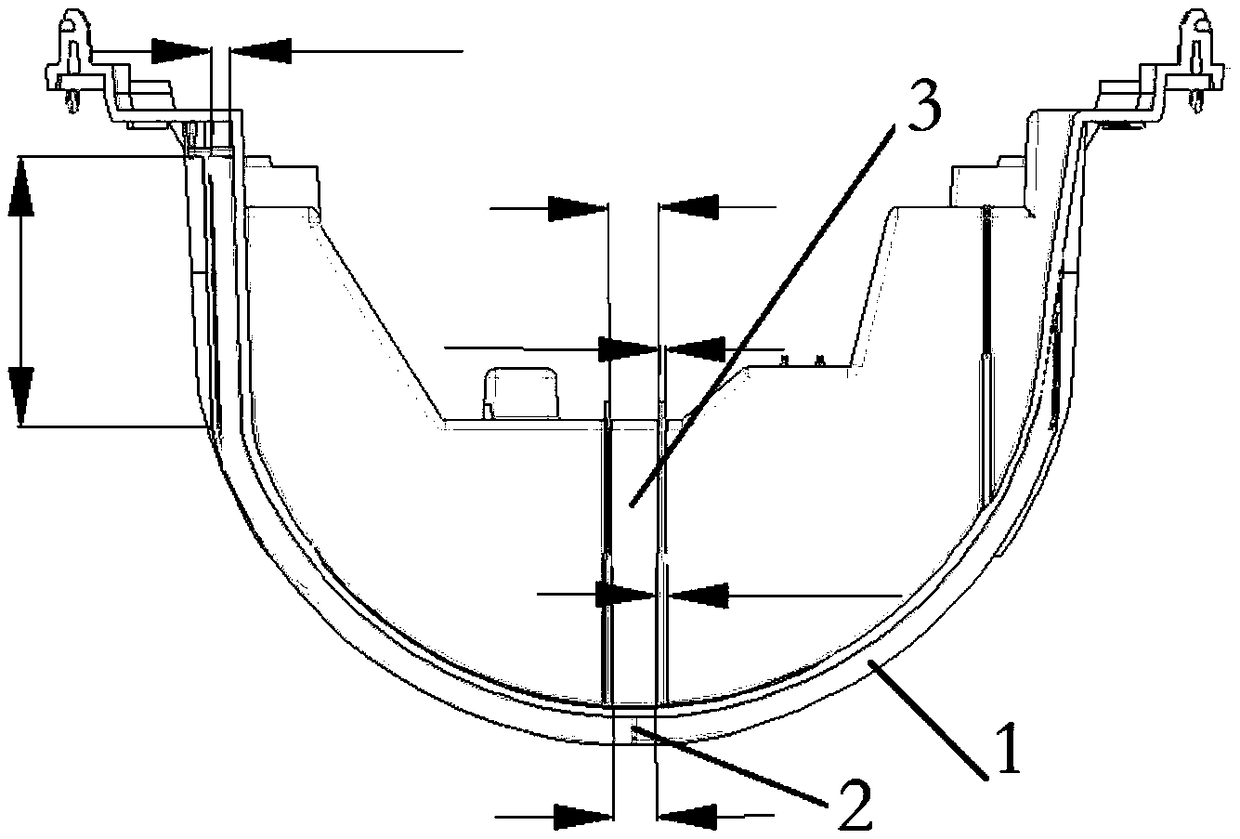

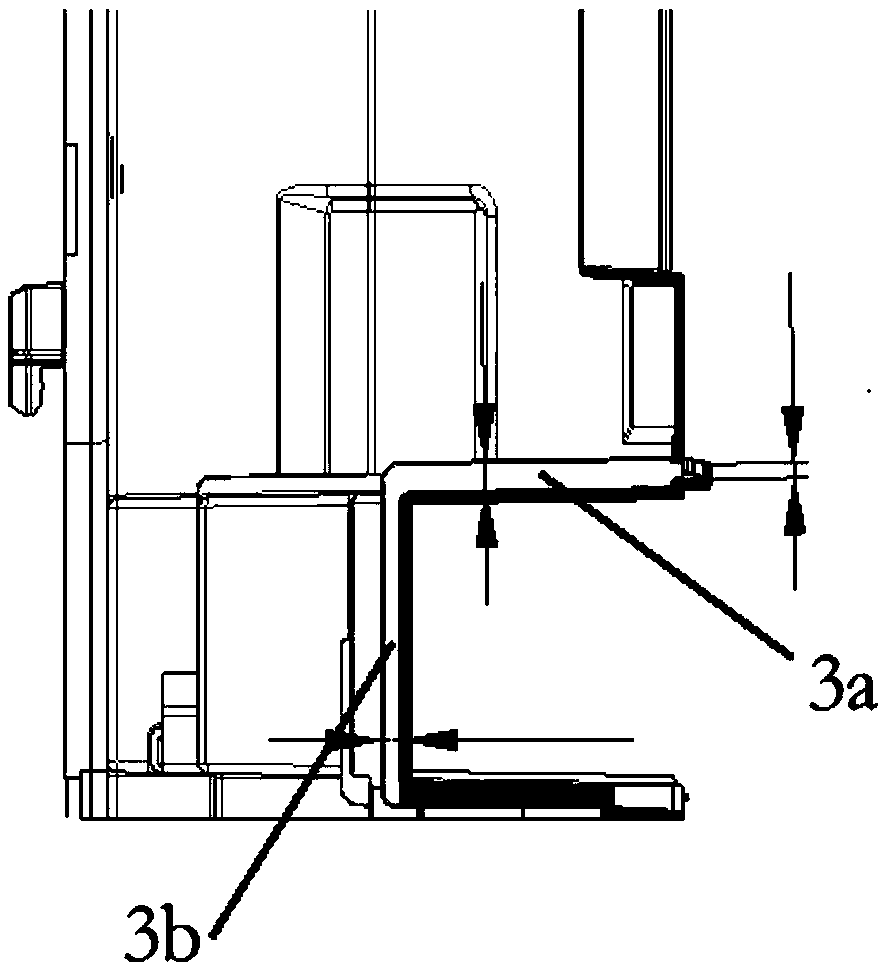

[0021] The lower moving part of the cabinet unit is located at the lower end of the water receiving tank 1 of the support plate (skeleton), and the outside of the water receiving tank 1 is the air outlet panel part. The outer edge of the air outlet panel and the water receiving tank 1 must have a gap of more than 5 mm, and that is, the upper edge of the water receiving tank 1 needs to keep a distance of more than 10 mm from the grille on the air outlet panel part. The space here is extremely small, and the structure of the docking sink 1 has many restrictions, so the traditional method of adding water bowls to divert water cannot be used. Therefore, according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com