A method for testing pile side friction resistance

A test method and friction resistance technology, which is applied in the test of basic structure, construction, basic structure engineering, etc., to achieve the effect of reducing the test work intensity, guaranteeing the test results, significant rationality and superiority

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

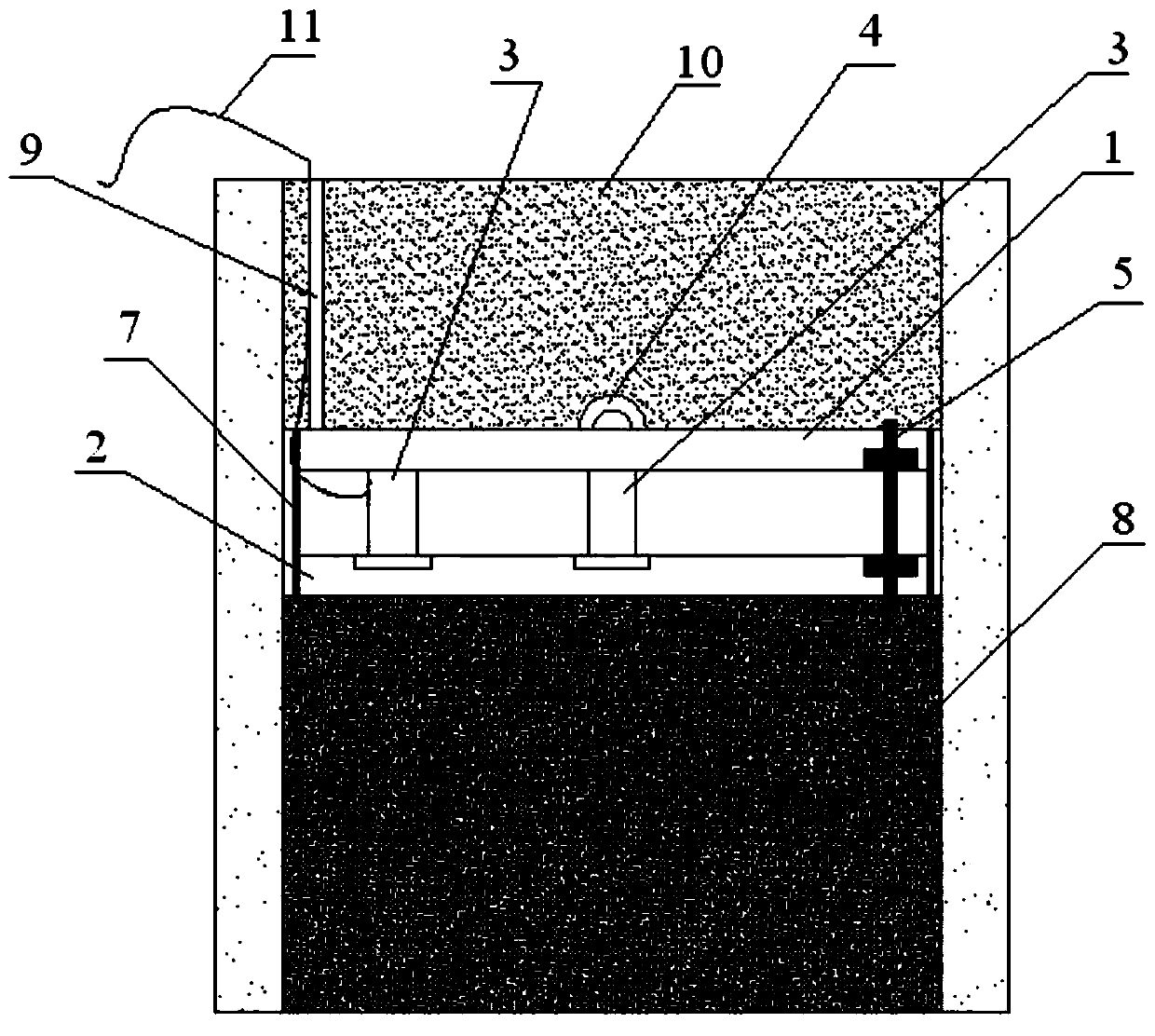

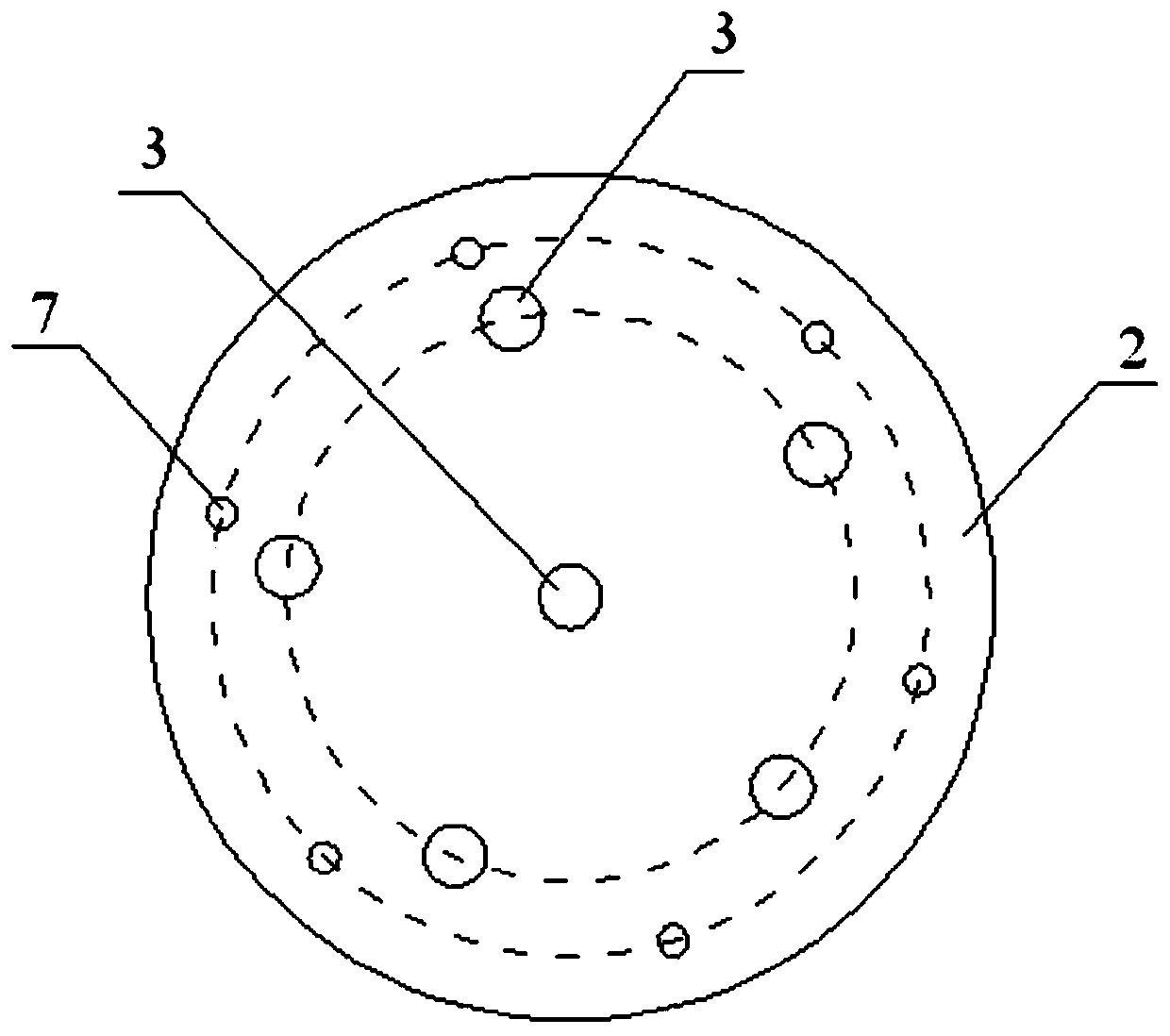

[0033] see figure 1 with figure 2 Shown:

[0034] The test method of pile side friction resistance provided by the invention, its method is as follows:

[0035] Step 1. Fabrication of the load box:

[0036] Use steel plates to make two discs with a diameter smaller than the diameter of the pile to be measured, which are respectively used as the upper pressure plate 1 and the lower pressure plate 2, and then fix several anchor cables 3 on the lower pressure plate 2, and one of the anchor cables The gauge 3 is located at the center of the lower pressure bearing plate 2, and the other anchor cable gauges 3 are evenly distributed on a concentric circle near the outer side of the lower pressure bearing plate 2; a lifting ring 4 is welded at the center of the upper pressure bearing plate 1 for lifting; Finally, the upper pressure bearing plate 1 and the lower pressure bearing plate 2 are connected by six tooth bars 5, each tooth bar 5 is equipped with a nut, and a light protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com