Method for high-density culture of D-pantolactone hydrolase producing fungi and application thereof

A pantolactone and high-density culture technology is applied in the field of high-density culture of D-pantolactone hydrolase-producing bacteria, and can solve the problem of low conversion rate of D-pantoate enzyme and conversion of D-pantoate acid. The problems of low fermentation rate, low fermentation density and low enzyme activity can achieve the effect of improving enzyme activity energy, high biomass and enzyme activity, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

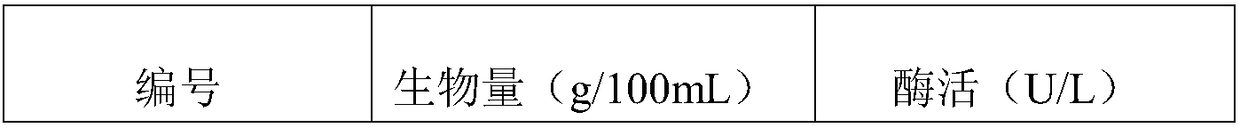

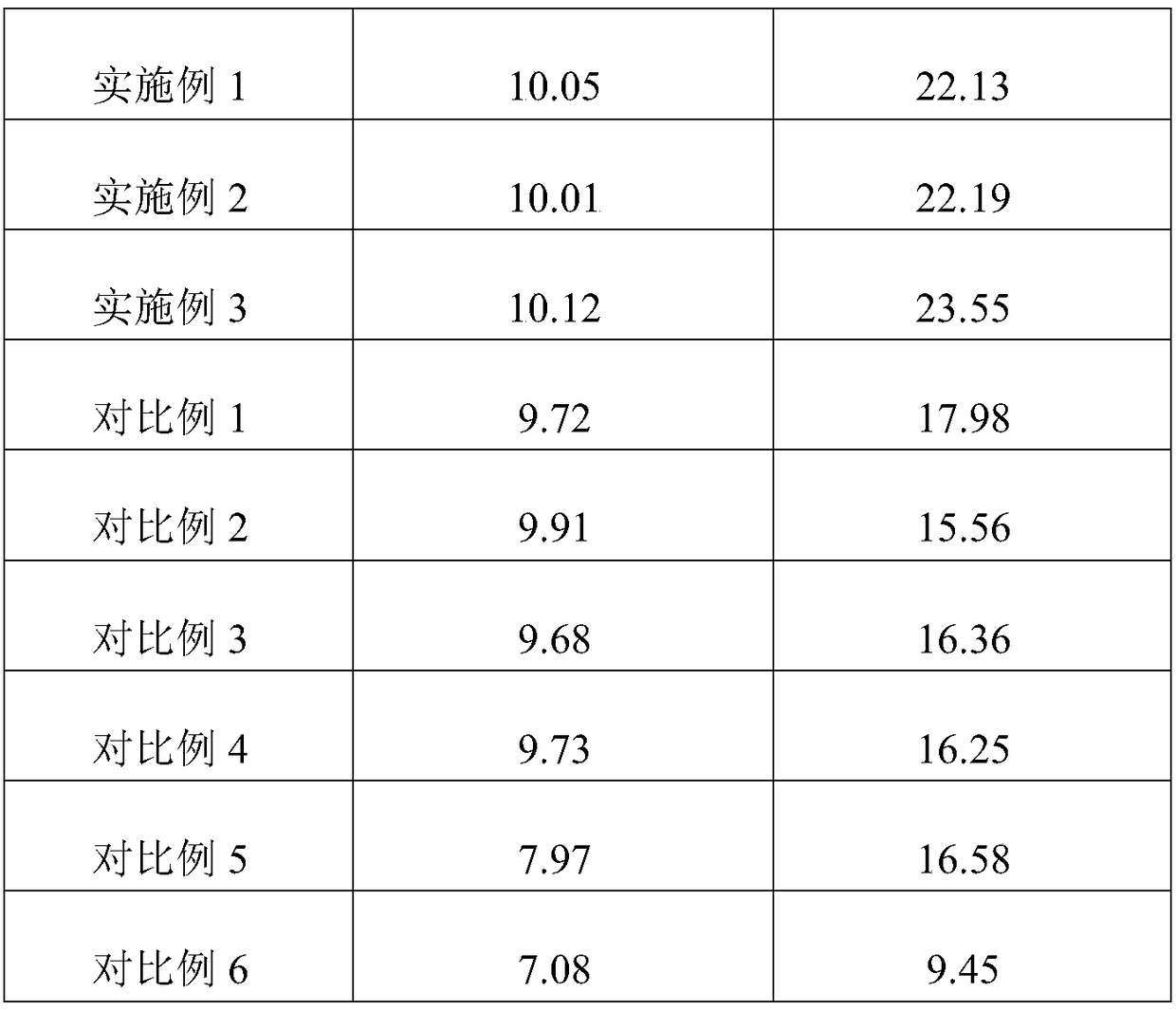

Embodiment 15

[0026] Embodiment 1 5L fermentation tank fermentation

[0027] The method for high-density cultivation of D-pantolactone hydrolase-producing bacteria described in this embodiment comprises the following steps:

[0028] (1) Inoculate one loop of Fusarium moniliforme through the LB plate culture and activation culture into the seed medium for seed activation, control the culture temperature to 30°C, control the shaker speed to 140rpm, and culture time to 10h , to obtain the seed solution;

[0029] The seed culture medium comprises: glycerin 5g / L, water chestnut pulp 30g / L, peptone 6g / L, asparagine 8g / L, ammonium sulfate 2g / L, adjust pH 7.0-8.0; Cleanly peeled water chestnuts are used as raw materials, which are obtained by adding an equal amount of water through pulping;

[0030] (2) Inoculate the activated seed liquid into a 5L fermenter with 2.5L fermentation medium according to the inoculum amount of 10% and carry out fermentation culture. The control culture temperature is...

Embodiment 25

[0033] Embodiment 2 5L fermentation tank fermentation

[0034] The method for high-density cultivation of D-pantolactone hydrolase-producing bacteria described in this embodiment comprises the following steps:

[0035] (1) Use an inoculation loop to inoculate one loop of Fusarium moniliforme cultured on the LB plate and activated culture into the seed medium for seed activation, control the culture temperature to 25°C, control the shaker speed to 160rpm, and culture time to 10h , to obtain the seed solution;

[0036] The seed culture medium comprises: glycerin 10g / L, water chestnut pulp 20g / L, peptone 10g / L, asparagine 3g / L, ammonium sulfate 4g / L, adjust pH 7.0-8.0; Cleanly peeled water chestnuts are used as raw materials, which are obtained by adding an equal amount of water through pulping;

[0037](2) Inoculate the activated seed liquid into a 5L fermenter with 2.5L fermentation medium according to the inoculation amount of 10%, and carry out fermentation culture. The con...

Embodiment 35

[0040] Example 3 Fermentation in a 5L fermenter

[0041] The method for high-density cultivation of D-pantolactone hydrolase-producing bacteria described in this embodiment comprises the following steps:

[0042] (1) Inoculate one loop of Fusarium moniliforme through the LB plate culture and activation culture into the seed medium for seed activation, control the culture temperature to 28°C, control the shaker speed to 150rpm, and culture time to 10h , to obtain the seed solution;

[0043] The seed culture medium comprises: glycerol 8g / L, water chestnut pulp 25g / L, peptone 8g / L, asparagine 5g / L, ammonium sulfate 3g / L, adjust pH 7.0-8.0; Cleanly peeled water chestnuts are used as raw materials, which are obtained by adding an equal amount of water through pulping;

[0044] (2) Inoculate the activated seed liquid into a 5L fermenter equipped with 2.5L fermentation medium according to 10% inoculum size and carry out fermentation culture. The control culture temperature is 28°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com