Method for carrying out printing operation on inkjet printing machine

An inkjet printing machine, printing process technology, applied in the direction of printing, data processing input/output process, printing device, etc., can solve the problems of not being able to realize the ink limit, lack of test patterns, and not considering the calibration of printing machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

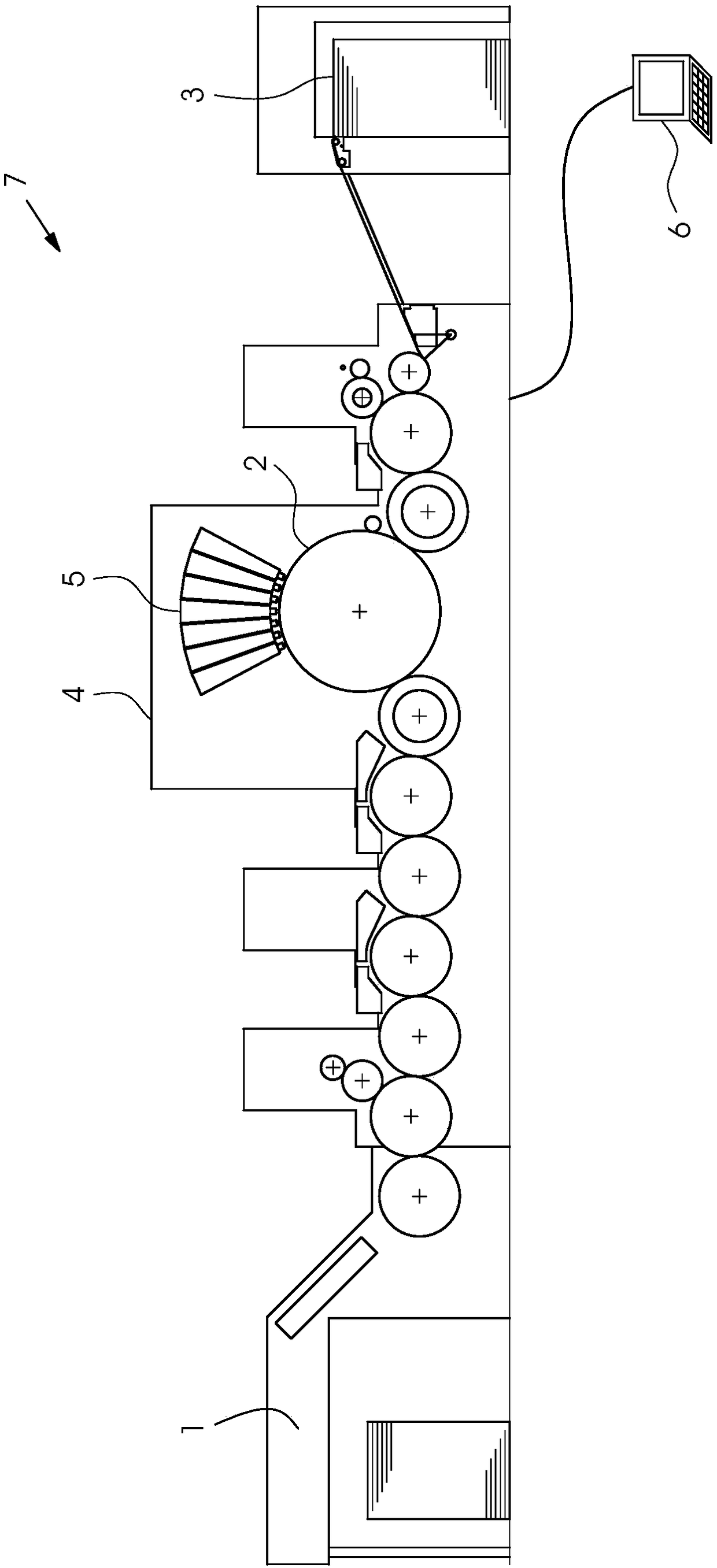

[0034] The field of application of the preferred embodiment variant is the inkjet printer 7 . exist figure 1 An example of the basic structure of the machine 7 is shown in , which comprises a feeder 1 up to an outfeed 3 for feeding a printed substrate 2 to a printing unit 4 in which the printed substrate is Printed by print head 5. The machine is here an inkjet sheet printing press 7 , which is controlled by a control computer 6 .

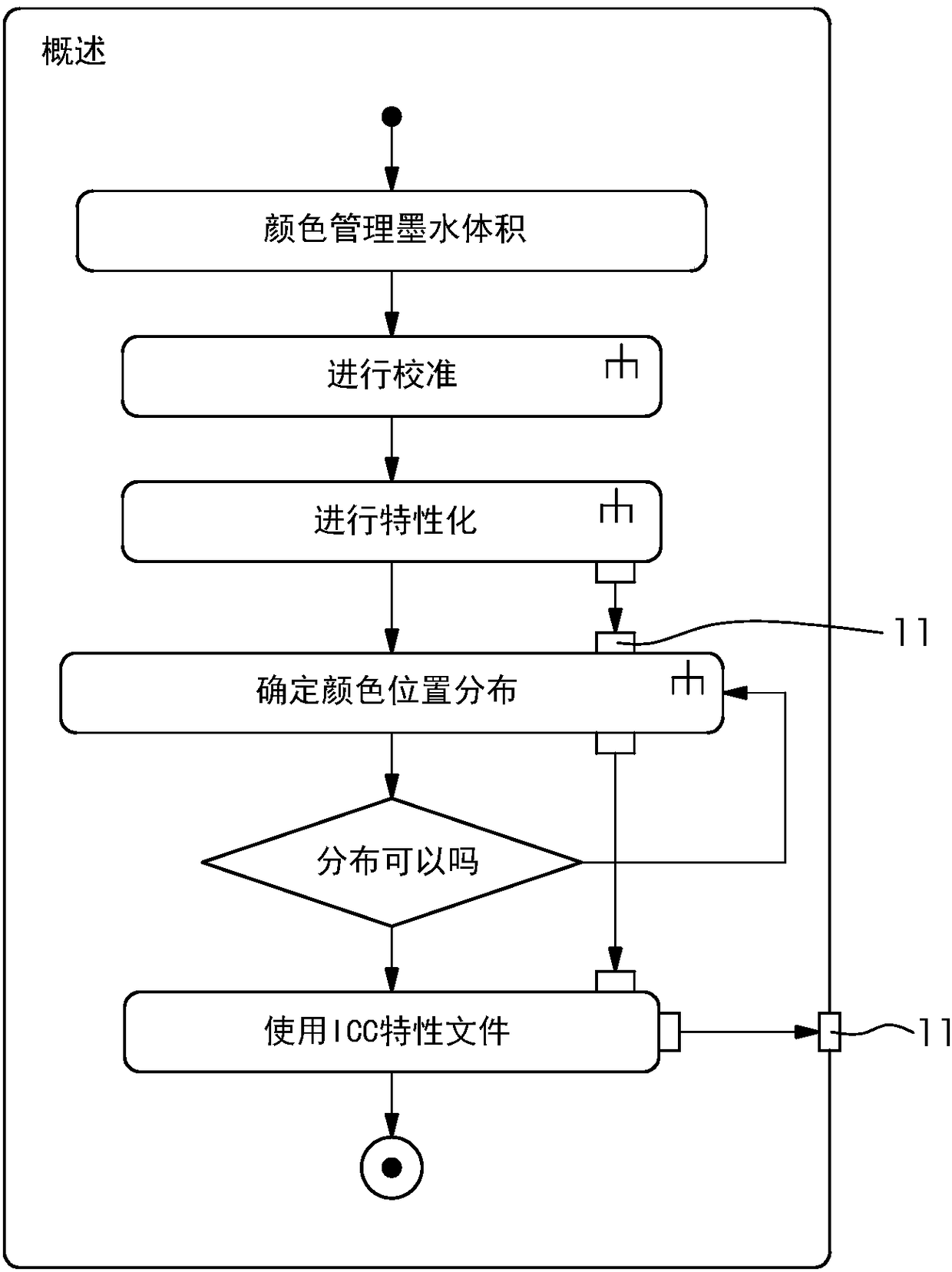

[0035] According to the basic schematic flow process of the method of the present invention in figure 2 shown in . Here, the method comprises four substeps. First, the inkjet printer 7 used is calibrated. This process is Figure 4 in detail. The calibration ends with the generation of a calibration characteristic curve of the printing press 7 .

[0036] A further important substep is the subsequent characterization in which the test patterns required for the color change are adjusted. This process is Figure 5 in detail. The most import...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com