A clutch device used for producing steel

A clutch device, steel technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult operation, complex structure, difficult installation and maintenance, etc., to achieve good safety performance, simple structure design, safety Performance and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further explained below in conjunction with the drawings and embodiments.

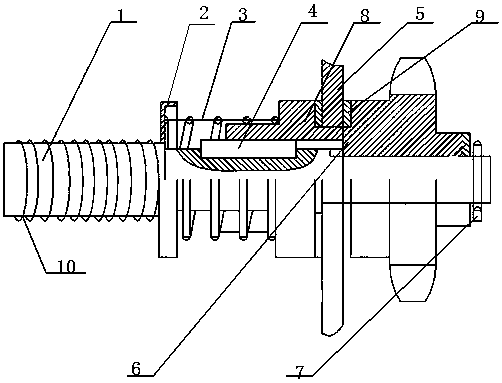

[0012] Such as figure 1 As shown, a clutch device for steel production includes a driving shaft 1, on which a pressure plate 2, a compression spring 3, a guide 4, a clutch pressure plate 5, a transmission gear 6 and a positioning pin 7 are sequentially sleeved, The clutch pressing plate 5 is fixedly connected by rivets 6, and an anti-wear sliding sleeve 8 is provided on the guide 4. An anti-wear pad 9 is provided outside the rivet 6, and the thickness of the anti-wear pad 9 is 1-4 mm. The pressure plate 2 or the clutch pressure plate 5 is made of high-temperature ceramic material, and the pressure plate 2 or the clutch pressure plate 5 is 2-3 cm. A number of reinforcing ribs 10 are provided on the driving shaft 1.

[0013] The invention has simple structure design, is suitable for large-scale industrial production, and has good safety performance and stability.

[0014...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com