Safety syringe and safety mechanism therefor

A safety syringe and safety mechanism technology, applied in the directions of syringes, hypodermic injection devices, infusion sets, etc., can solve the problems of time-consuming, prone to errors, etc., and achieve the effects of preventing accidental stab wounds, simple structure, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

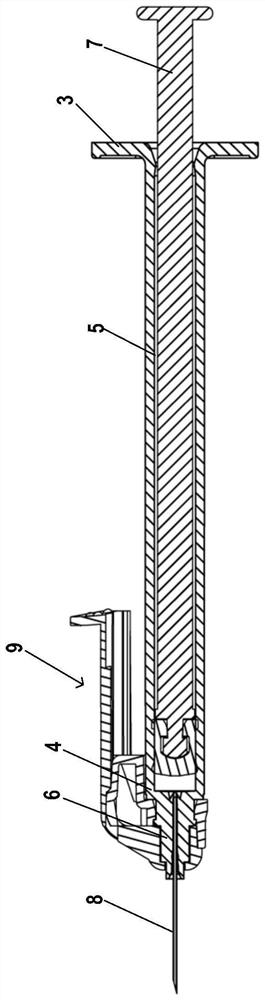

[0048] The structure and working principle of the safety syringe of the present invention, especially its safety mechanism, will be explained below with reference to the accompanying drawings. However, those skilled in the art should understand that the safety mechanism of the present invention is not limited to syringes, and can also be applied to other medical devices, such as blood collection needles. The "proximal side", "far side", "proximal end" and "distal end" mentioned in this article are all relative to the injection operation of the medical staff, and the side or end close to the medical staff performing the injection operation is "proximal side" and "proximal end", and "distal side" and "distal end" on the side or end away from the medical staff performing the injection.

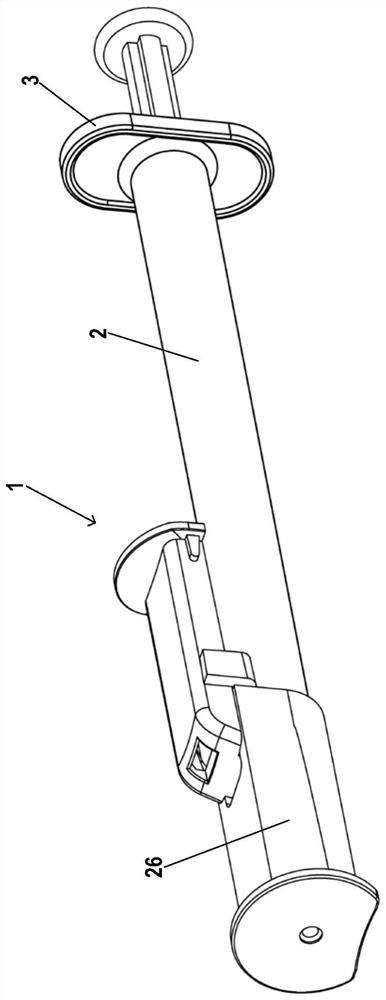

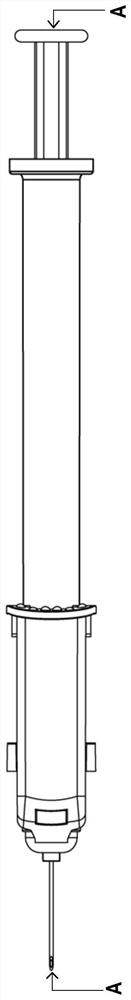

[0049] figure 1 is a perspective view of a safety syringe with a needle shield according to an embodiment of the present invention. The safety syringe 1 comprises a barrel 2 , a plunger 7 , a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com