Dust collector and operation method thereof

An operation method and technology of vacuum cleaners, which are applied in the directions of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems of laborious operation and inconvenient use when the vacuum cleaner pours dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

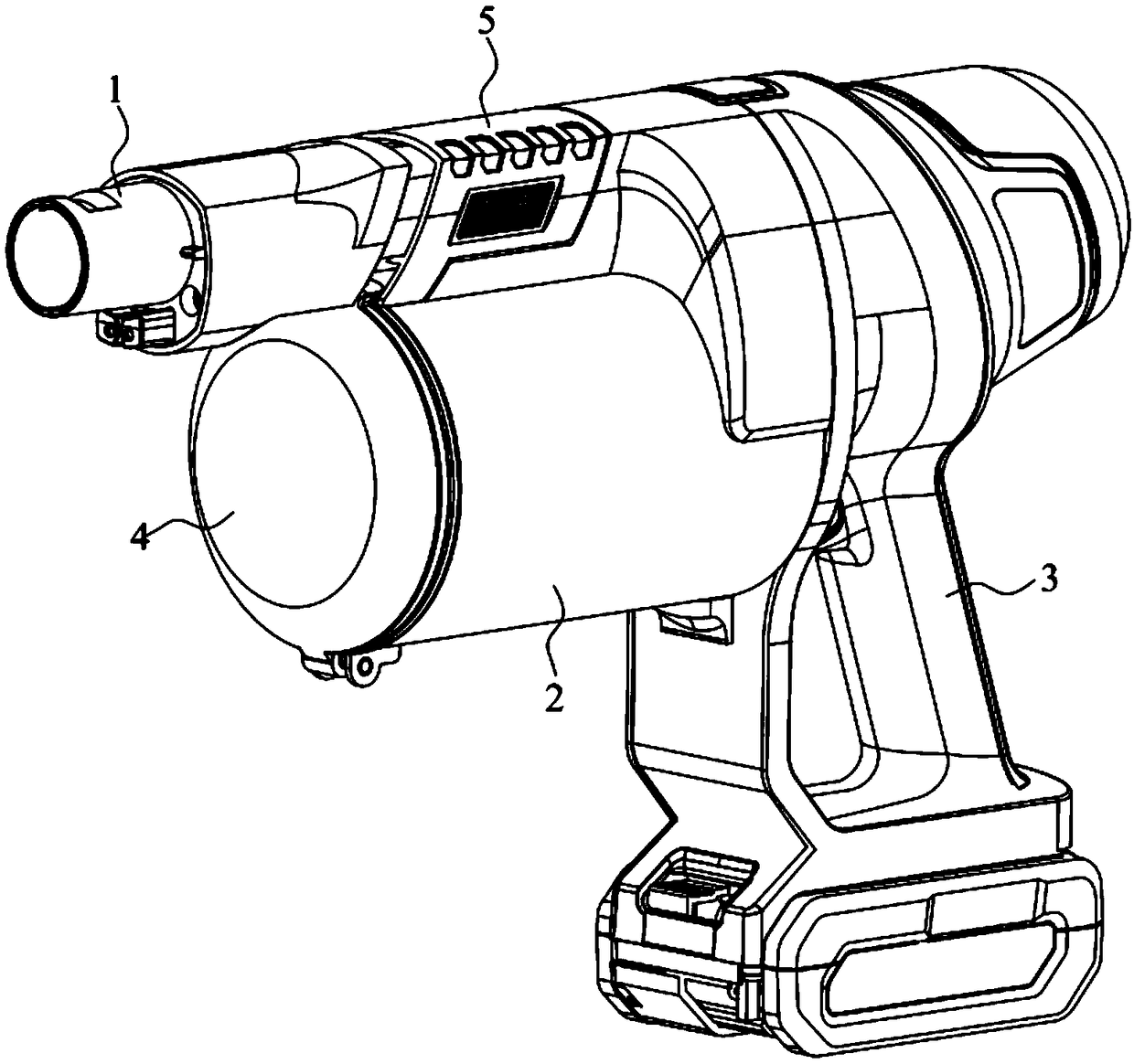

[0036] see Figure 1 to Figure 4 , the embodiment of the present invention provides a vacuum cleaner, including an air intake pipe 1, a dust cup 2, a handle 3 and a cup cover 4, the dust cup 2 is located on the lower side of the air intake pipe 1, and one end is connected to the handle 3, and the dust cup 2 is far away from the handle 3 One end of the container is provided with an ash outlet 21, and the ash outlet 21 is provided with a cup cover 4, and the cup cover 4 can open or close the ash outlet 21.

[0037] One end of the cup cover 4 close to the intake pipe 1 is clamped with the dust cup 2, and the other end of the cup cover 4 is hinged with the dust cup 2; Sliding in the direction of the axis to push the cup cover 4 and the dust cup 2 out of engagement. The clamping method of the cup cover 4 and the dust cup 2 can be a lock, a clip or a buckle assembly. During the sliding process, the slider 5 unlocks the clip joint between the cup cover 4 and the dust cup 2, so that ...

Embodiment 2

[0049] Figure 15 Embodiment 2 is shown, in which components identical or corresponding to those in Embodiment 1 are identified with reference numerals corresponding to Embodiment 1. For simplicity, only the differences between Embodiment 2 and Embodiment 1 are described. The difference is that an operating part 54 is provided on at least one side of the main body part 52 , and when the sliding part 5 is pushed by hand, the hand contacts the operating part 54 , which is convenient for pushing the sliding part 5 smoothly.

[0050] In this embodiment, the operating part 54 is disposed at an end of the friction part 53 close to the cup cover 4 . When pushing the sliding part 5 by hand, under the cooperation of the friction part 53 and the operating part 54, the hand is limited, so that the hand is in close contact with the sliding part 5, which is convenient for pushing the sliding part 5 smoothly.

[0051] The embodiment of the present invention also provides a method for oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com