Preparation method of zinc-based complex lithium ion battery negative electrode material

A technology of lithium ion battery and negative electrode material, applied in electrode manufacturing, battery electrode, secondary battery manufacturing, etc., to achieve the effects of novel structure, low price, and low requirements for synthesis equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

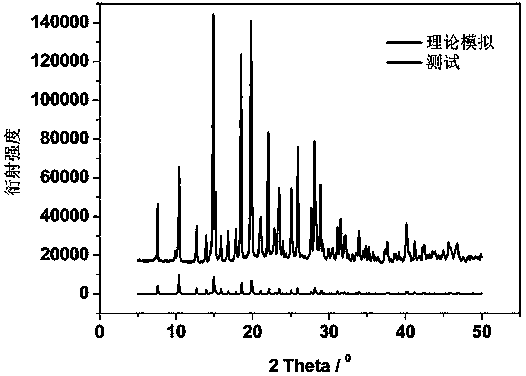

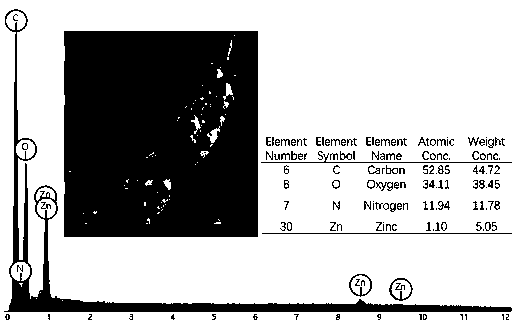

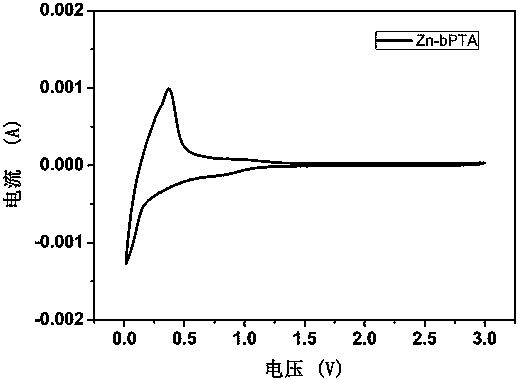

[0041] Embodiment 1: Zn(NO 3 ) 2 ·6H 2 O (1.0 mmol, 297 mg), H 2 bcbpy·2Cl (0.5 mmol, 258 mg), HOOCC 6 h 4 COOH (1.0 mmol, 166 mg), NH 4 PF 6 (1.0 mmol, 163 mg) were mixed, added to a mixed solution of distilled water (8 mL) and DMF (8 mL), and stirred for 30 min at room temperature under an air atmosphere. Then the mixed liquid was transferred to a 25ml Teflon autoclave and heated to 120 °C for 24 h. After the reaction, the temperature was lowered to room temperature at a rate of 10 ˚C / h to obtain white needle-like crystals, which were filtered, washed, and dried to obtain the complex Zn-bPTA with a calculated yield of about 83%. The obtained Zn-bPTA electrode material was ground and passed through a 300-mesh sieve. According to the metal complex Zn-bPTA (0.6g), PVDF (0.1g), KS6 (0.2g), Super-P (0.1g) according to the mass ratio of 60:10:20:10 to configure a mixture, add the solvent NMP (2.5 g), after stirring for 2 h, a black viscous electrode slurry was prepared. ...

Embodiment 2

[0043] Embodiment 2: Zn(NO 3 ) 2 ·6H 2 O (2.0 mmol, 594 mg), H 2 bcbpy·2Cl (1.0 mmol, 516 mg), HOOCC 6 h 4 COOH (2.0 mmol, 332 mg), NH 4 PF 6 (2.0 mmol, 326 mg) were mixed, added to a mixed solution of distilled water (16 mL) and DMF (16 mL), and stirred at room temperature under an air atmosphere for 60 min. Then the mixed liquid was transferred to a 50 ml Teflon autoclave and heated to 120 °C for 24 h. After the reaction was completed, the temperature was lowered to room temperature at a rate of 10°C / h to obtain white needle-like crystals, which were filtered, washed, and dried to obtain the complex Zn-bPTA, with a calculated yield of about 82%. The obtained Zn-bPTA electrode material was ground and passed through a 300-mesh sieve. According to the metal complex Zn-bPTA (0.5g), PVDF (0.1g), KS6 (0.2g), Super-P (0.2g) according to the mass ratio of 50:10:20:20 to configure a mixture, add the solvent NMP (2.5 g), after stirring for 2 h, a black viscous electrode slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com