Harmonic-reducer flexible-wheel structure design and optimization method

A technology of harmonic reducer and structural design, applied in design optimization/simulation, instrument, calculation, etc., can solve problems such as radial warping of gear teeth, and achieve the effect of low processing cost, realization of design parameters, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A method for designing and optimizing a flexible wheel structure of a harmonic reducer, specifically comprising the following steps:

[0020] The first step, initial scheme design

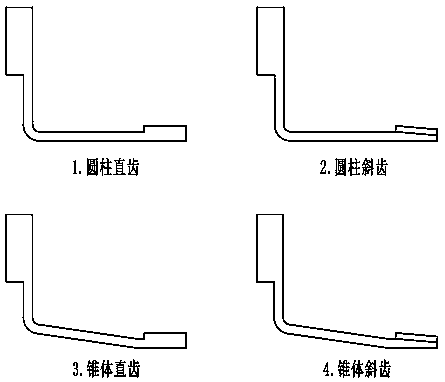

[0021] 1.1 For the contradictory analysis of tooth warpage, four different forms of flexspline models are established, such as figure 1 shown;

[0022] The second step, eigenvalue solution and solution screening

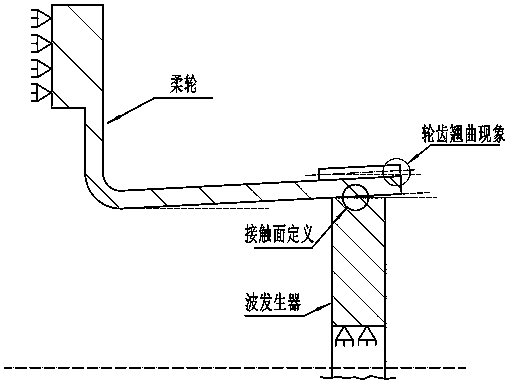

[0023] 2.1 Use the interactive interface to import the model assembled with the wave generator into Ansys Workbench (AW), apply fixed constraints on the left end surface of the flexspline and the inner hole of the wave generator, and use a hexahedral mesh as a whole to define the inner wall of the flexspline and the wave generator There is no friction between the contact surfaces of the outer wall of the device, the normal contact stiffness is 0.01, and the limited penetration depth is 0.01mm, such as figure 2 shown;

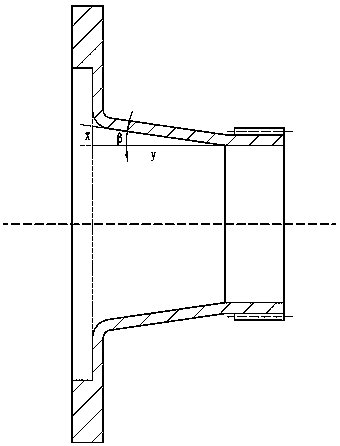

[0024] 2.2 The path direction of the flexspline tooth defi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com