Fully sealed powder sampler and sampling method thereof

A sampler and fully-sealed technology, applied in the field of fully-sealed powder samplers, can solve problems such as damage, wasting time, increasing damage, etc., achieving the effect of simple and compact structure, ensuring safety, and reducing the use of cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings of the description.

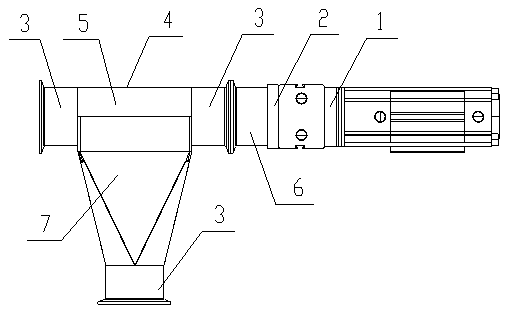

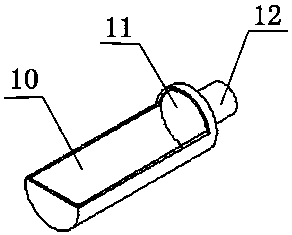

[0027] Such as Figure 1-3 As shown, the fully-sealed powder sampler includes an extension swing cylinder 1, a mounting plate 2, a first quick fitting 3, a sampling hopper 4, a horizontal storage channel 5, a second quick fitting 6, a vertical delivery channel 7, The sampler 8, the pendulum rod 9, the sampling tank 10, the blocking plate 11 and the connection block 12.

[0028] The sampling bucket 4 is fixedly arranged on the stretching swing cylinder 1, and the sampler 8 is arranged in the sampling bucket 4 and is connected with the stretching swing cylinder 1. The sampler 8 includes a sampling tank 10 and a connecting block 12 arranged on one side of the sampling tank 10. A baffle 11 is provided between the groove 10 and the connecting block 12, and the baffle 11 cooperates with the horizontal accommodation channel 5 to prevent the sample from spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com